A kind of method for preparing highly emulsifying egg white emulsion

A technology of emulsifying and egg white liquid, which is applied in the field of preparation of highly emulsifying egg white emulsion, to achieve the effect of improving efficiency, simple process flow and improving emulsifying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

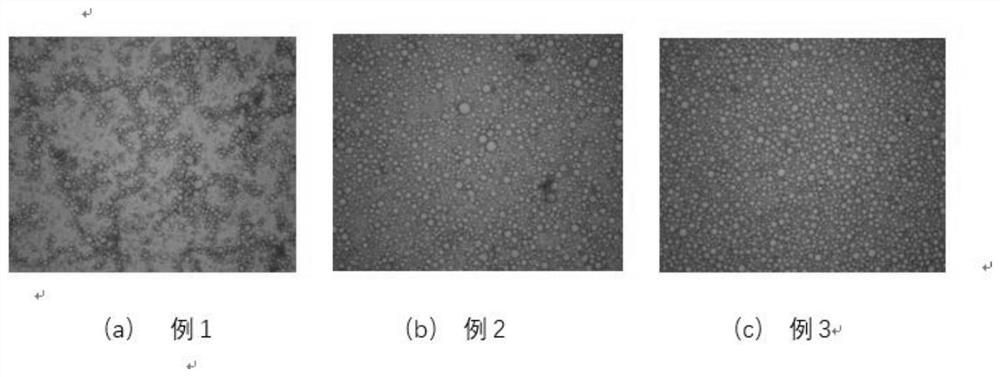

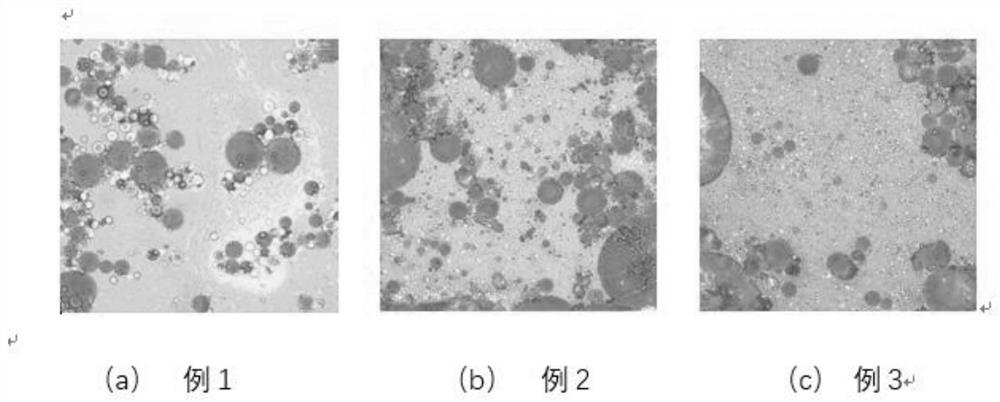

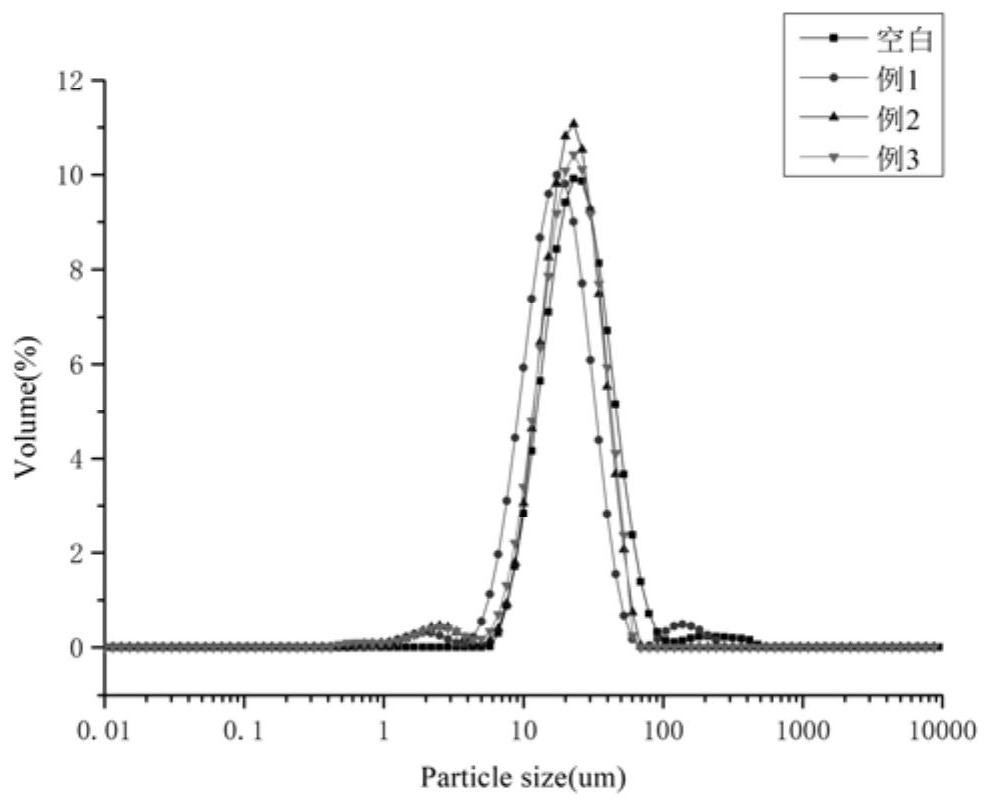

Embodiment 1

[0025] 1) Pretreatment of egg white:

[0026] Separate the egg white from the egg yolk and pick out the ligature in the egg white, stir the egg white evenly with an electric mixer at a stirring speed of 400rpm for 30min, and then vacuum pack it in a sealed bag.

[0027] 2) Co-60 gamma ray treatment:

[0028] The packaged egg white was irradiated with a Co-60γ source supported by the Hubei Academy of Agricultural Sciences, and the sample was irradiated at a dose rate of 3.4 kGy / h, and the radiation dose received by the sample was 1 kGy.

[0029] 3) Add organic acid

[0030] Taking out the irradiated egg white, adding acetic acid with a weight concentration of 1% to the egg white, and adjusting the pH of the egg white to 6;

[0031] 4) Preparation of egg white emulsion

[0032] Dissolve the egg white in water to make an egg white solution with a weight concentration of 15%, then add soybean oil to the egg white solution according to 20% of the volume of the egg white solution...

Embodiment 2

[0034] 1) Pretreatment of egg white:

[0035] Separate the egg whites from the egg yolks and pick out the strings in the egg whites. Stir the egg whites evenly and pack them in a vacuum-sealed bag.

[0036] 2) Co-60 gamma ray treatment:

[0037] The packaged egg white was irradiated with a Co-60γ source, and the sample was irradiated at a dose rate of 4 kGy / h, and the radiation dose received by the sample was 3 kGy.

[0038] 3) Add organic acid

[0039] The irradiated egg white was taken out, and a citric acid solution with a weight concentration of 10% was added to the egg white to adjust the pH of the solution to 5.

[0040] 4) Preparation of egg white emulsion

[0041] Dissolve the egg white in water to prepare an egg white solution with a weight concentration of 6%, then add soybean oil to the egg white solution according to 40% of the volume of the egg white solution, first use a high-speed shear homogenizer at room temperature at 8000rpm for 3 minutes, Then use a hig...

Embodiment 3

[0043] 1) Pretreatment of egg white:

[0044] Separate the egg whites from the egg yolks and pick out the strings in the egg whites. Stir the egg whites evenly and pack them in a vacuum-sealed bag.

[0045] 2) Co-60 gamma ray treatment:

[0046] The packaged egg white was irradiated with a Co-60γ source, and the sample was irradiated at a dose rate of 4.5 kGy / h, and the radiation dose received by the sample was 5 kGy.

[0047] 3) Add organic acid

[0048] The irradiated egg white was taken out, and a 5% malic acid solution by weight was added to the egg white to adjust the pH of the solution to 4.

[0049] 4) Preparation of egg white emulsion

[0050] Dissolve the egg white in water to prepare an egg white solution with a weight concentration of 10%, then add soybean oil to the egg white solution according to 30% of the volume of the egg white solution, first use a high-speed shear homogenizer at room temperature at 9000rpm for 3 minutes, Then use a high-pressure homogeniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com