Fiber curtain smoke and spark insulating device for bag type dust collector

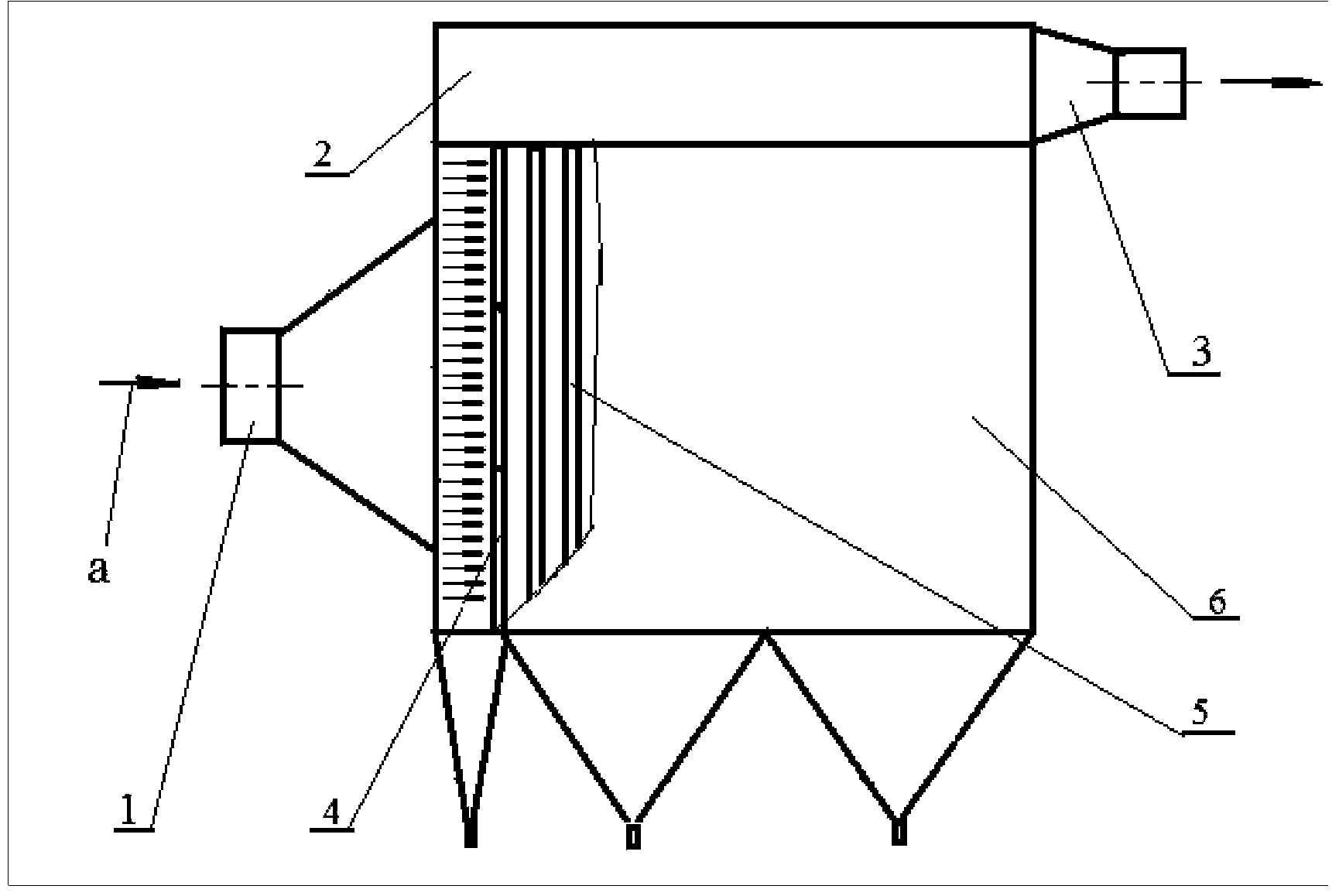

A bag-type dust collector and barrier device technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of reduced barrier effect, large gap between rotating blades, and filter bag burning, and increase the probability of collision. , The effect of reducing impact wear and uniform velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

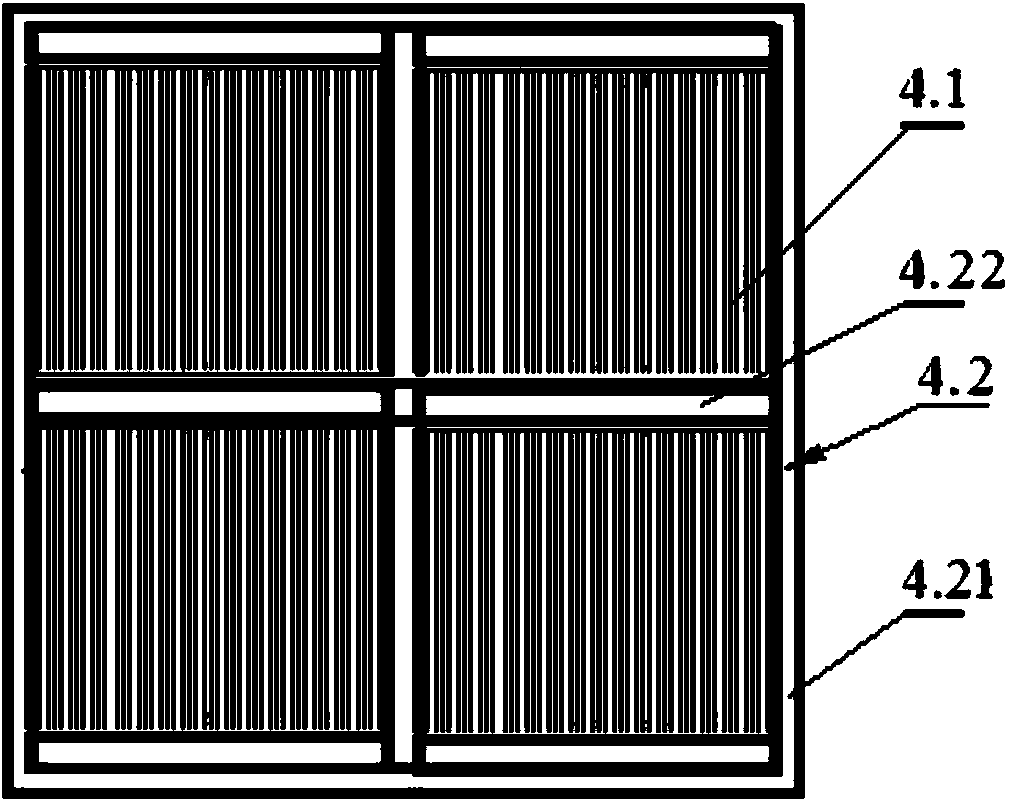

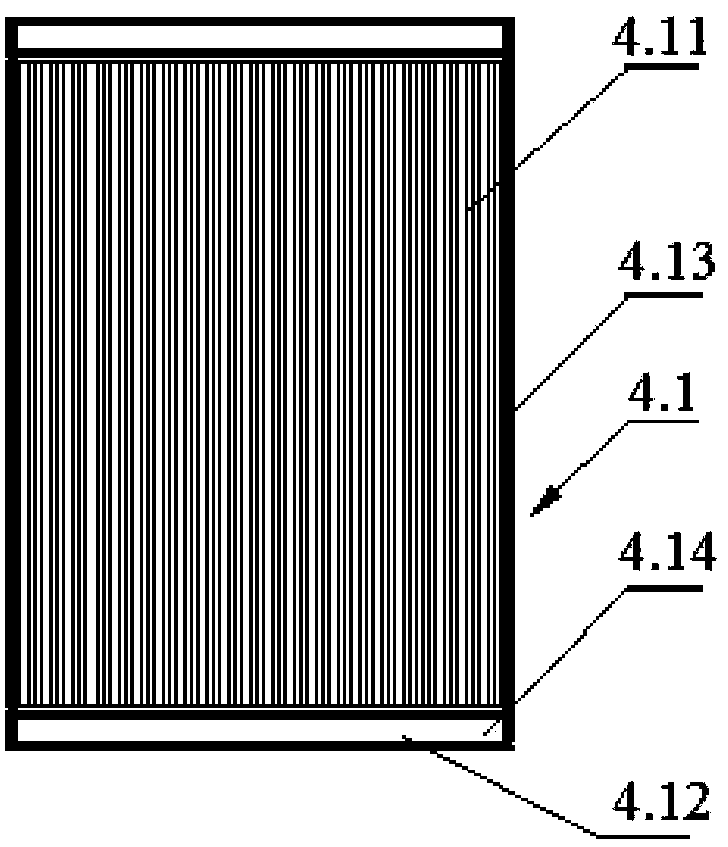

[0021] Such as figure 2 — Figure 4 As shown, the fiber curtain smoke and spark blocking device 4 of the present invention includes one or more fiber curtain units 4.1 arranged in the fiber curtain frame 4.2, and the fiber curtain unit 4.1 includes several shaken fiber filaments arranged vertically and parallel 4.11. The fiber filaments 4.11 are arranged into one or more layers of fiber curtains. The diameter of the fiber filaments 4.11 is 0.1mm-1mm, and the gap between the adjacent fiber filaments 4.11 is 0.1-0.5mm. The material of the fiber filament 4.11 is stainless steel wire.

[0022] In the above scheme, the fiber filaments of each adjacent layer in the multi-layer fiber curtain are arranged in a staggered manner, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com