Multi-functional molding machine for air hoses

A forming machine and multi-functional technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems that the diameter of the pipe collar cannot be adjusted, the metal plate cannot be smoothly exported, and the bending degree of the hoop bar cannot be adjusted. , to achieve the effect of simplifying the machine structure and operation process, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

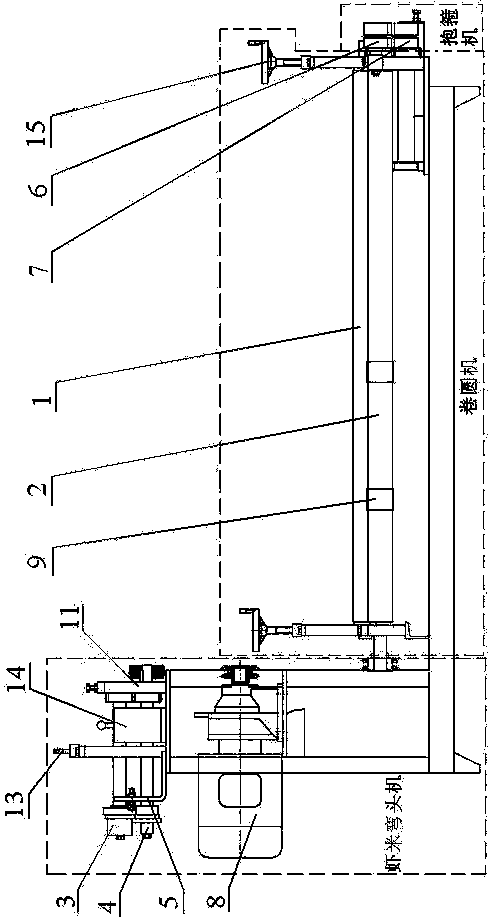

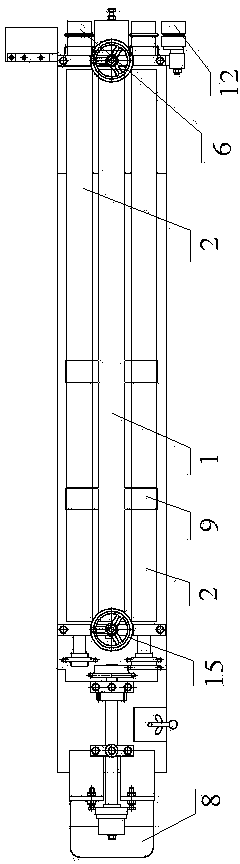

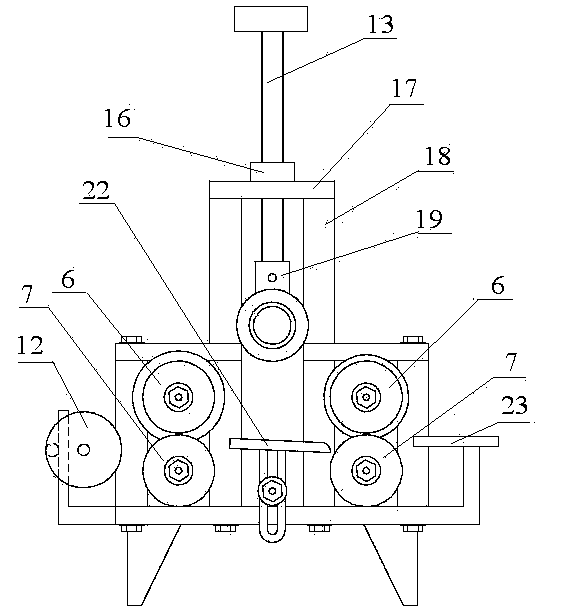

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] The structure of a multifunctional air duct forming machine of the present invention is as follows: Figure 1-4 As shown, it includes a rolling machine for bending and forming sheet metal parts, a shrimp elbow machine for connecting and forming dispersed curved duct segments, and a duct assembly for several segments composed of dispersed ducts. The connected hoop machine, the round machine, the shrimp elbow machine and the hoop machine are fixedly connected to each other. The rolling machine includes an upper pressing roller shaft 1 and a lower feeding roller shaft 2 arranged parallel to each other and rotatable, and the upper pressing roller shaft 1 is arranged in parallel above the lower feeding roller shaft 2; the dried shrimp elbow machine includes an upper die roller 3, The lower mold roller 4 and the limit baffle 5 used to limit the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com