Processing method and device for slaughter wastewater

A technology for slaughtering wastewater and treatment devices, which is applied in animal processing wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of high system operation and maintenance requirements, large construction investment costs, and high operating costs , to achieve the effect of low operator requirements, large construction investment costs, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

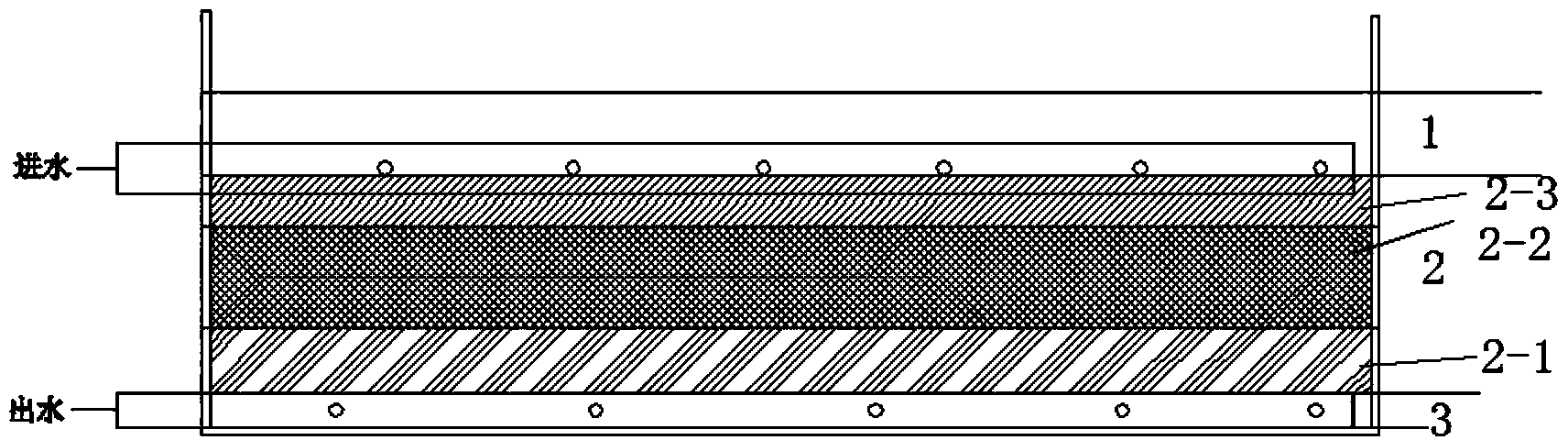

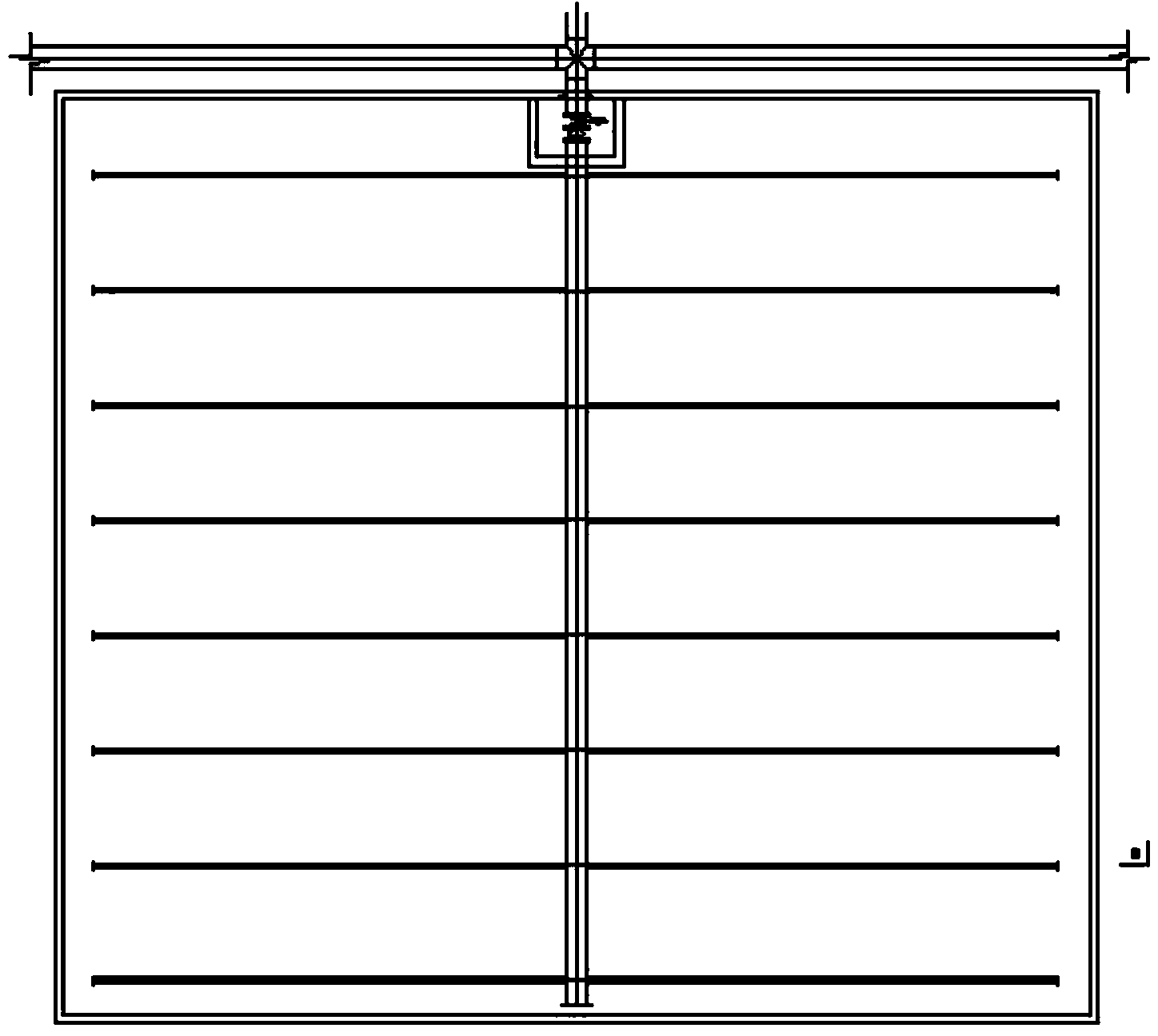

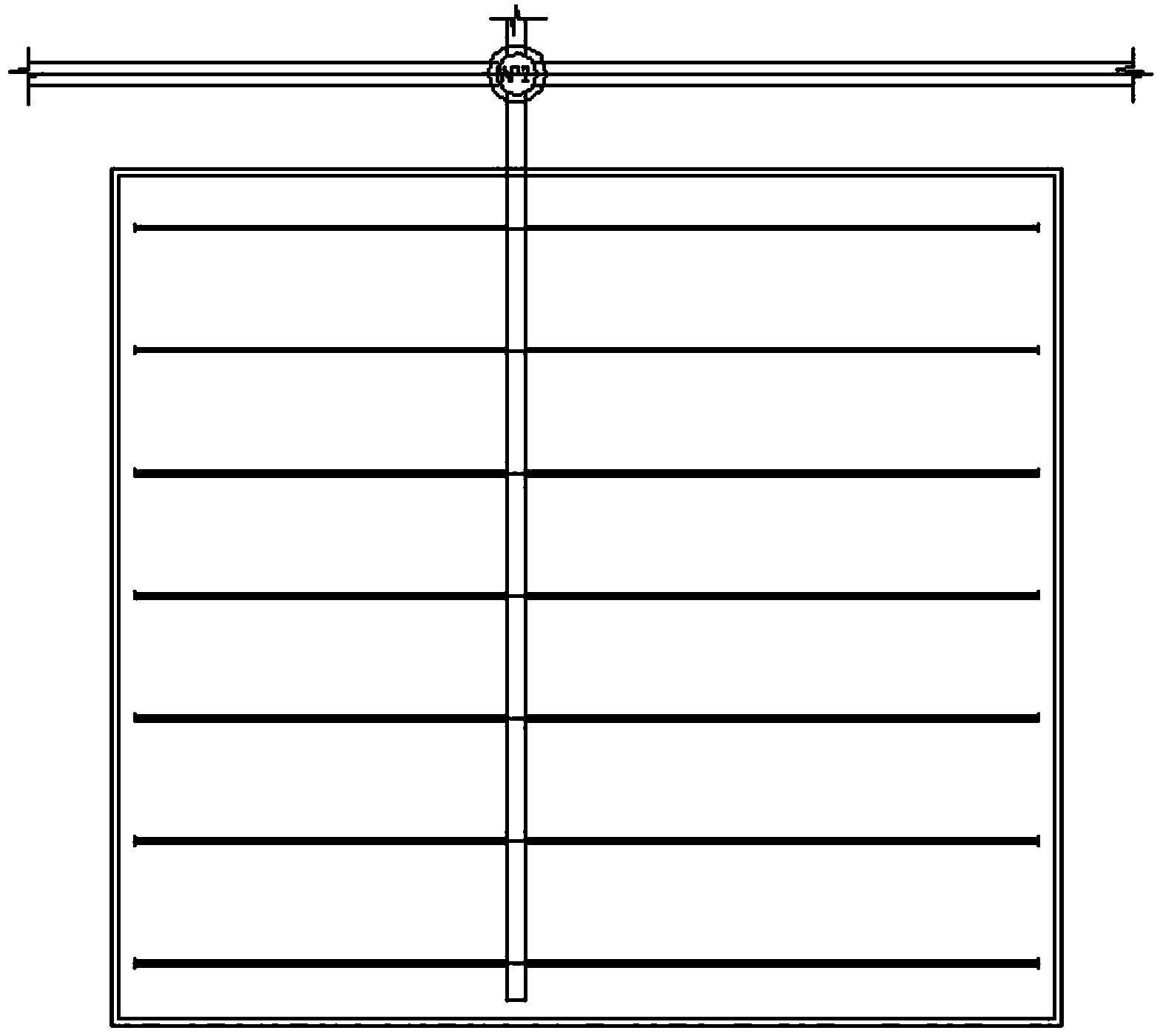

[0029] As shown in the figure, the water distribution system 1, the filtration system 2, the water collection system 3, and the water distribution pipe 4. The upper layer is a coarse and fine filter layer 2-3, 2-2, 2-1 is a supporting layer.

[0030] Taking a slaughter wastewater treatment station as an example, the relevant parameters are as follows:

[0031] 1. Design treatment water volume: 7000m3 / d;

[0032] 2. PH value: 6-9;

[0033] 3. Hydraulic load: 1.825m3 / (m2.d);

[0034] 4. Single pool area: 640m2;

[0035] 5. Arrangement form: double-row symmetrical arrangement;

[0036] 6. Single water distribution time: 30min;

[0037] 7. Single operation cycle: 6h;

[0038] 8. Single tank size: L×B×H=26.75m×23.9m×2.4m;

[0039] 9. Supporting layer height: 600mm (500mm+100mm);

[0040] 10. Filling layer height: 1200mm (500mm+700mm);

[0041] 11. The main and main pipes of water distribution are DN500 glass fiber reinforced plastics, and the branch pipes of water distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com