Leather greasing agent endowing leather with function of shielding ultraviolet ray and preparation method thereof

A technology of leather fatliquor and ultraviolet rays, applied in the direction of small raw hide/big raw hide/leather/fur treatment, leather impregnation, small raw hide/big raw hide/leather skin/fur chemical treatment, etc., to achieve the effect of avoiding phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

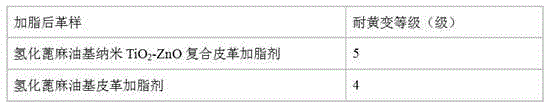

Examples

Embodiment 1

[0033] Step 1: Nano TiO 2 - Preparation and modification of ZnO composite particles:

[0034] Add 100mL of 1mol / L titanium tetrachloride solution and 1L of 2mol / L urea solution into a 75°C three-neck flask equipped with a reflux condenser, a stirring device and a temperature control device, and react in a constant temperature water bath for 2 hours;

[0035] Add 100mL of 5mol / L zinc chloride solution and 1mL of 1mol / L surfactant solution, raise the temperature to 90°C and react for 2h to obtain a white precipitate, which is centrifuged, washed, dried at 60°C for 24h in vacuum, and placed in a muffle furnace at 500°C Calcined for 2h to get nano-TiO 2 - ZnO composite particles;

[0036] Then 0.5g nano-TiO 2 -ZnO composite particles, 70mL of absolute ethanol and 5mL of water were added to a three-necked flask at 60°C, stirred for 30 minutes, adjusted to pH 9, and 25mL of absolute ethanol dissolved with 0.02g of modifier was slowly added dropwise, reacted in a constant temperat...

Embodiment 2

[0043] Step 1: Nano TiO 2 - Preparation and modification of ZnO composite particles:

[0044] Add 100mL of 1mol / L titanium tetrachloride solution and 1L of 2mol / L urea solution into a 76°C three-neck flask equipped with a reflux condenser, a stirring device and a temperature control device, and react in a constant temperature water bath for 2 hours;

[0045] Add 100mL of 4mol / L zinc chloride solution and 1mL of 1mol / L surfactant solution, raise the temperature to 90°C and react for 2h to obtain a white precipitate, which is centrifuged, washed, dried at 60°C for 24h in vacuum, and placed in a muffle furnace at 600°C Calcined for 2h to get nano-TiO 2 - ZnO composite particles;

[0046] Then 0.5g nano-TiO 2 -ZnO composite particles, 70mL of absolute ethanol and 5mL of water were added to a three-necked flask at 60°C, stirred for 30 minutes, adjusted to a pH of 9.5, and 25mL of absolute ethanol dissolved with 0.04g of modifier was slowly added dropwise, reacted in a constant t...

Embodiment 3

[0053] Step 1: Nano TiO 2 - Preparation and modification of ZnO composite particles:

[0054] Add 100mL of 1mol / L titanium tetrachloride solution and 1L of 2mol / L urea solution into a 77°C three-necked flask equipped with a reflux condenser, a stirring device and a temperature control device, and react in a constant temperature water bath for 2 hours;

[0055] Add 100mL of 3mol / L zinc chloride solution and 1mL of 1mol / L surfactant solution, raise the temperature to 90°C for 2h to obtain a white precipitate, centrifuge, wash, dry at 60°C for 24h in vacuum, and place in a muffle furnace at 700°C Calcined for 2h to get nano-TiO 2 - ZnO composite particles;

[0056] Then 0.5g nano-TiO 2 -ZnO composite particles, 70mL of absolute ethanol and 5mL of water were added to a three-necked flask at 60°C, stirred for 30 minutes, adjusted to pH 9, and 25mL of absolute ethanol dissolved with 0.06g of modifier was slowly added dropwise, reacted in a constant temperature water bath for 30mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com