Vanadium extraction process based on extraction-reverse extraction

A stripping agent and extraction technology, applied in the field of vanadium smelting, can solve the problems of high impurity content of vanadium products, high content of free chloride ions, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Adopt the method of the present invention to extract vanadium

[0045] 1. Test raw materials

[0046] (1) The chemical composition of vanadium-containing tailings is shown in Table 1;

[0047] Table 1 Chemical composition of vanadium-containing tailings (wt%)

[0048] Element

V 2 o 5

Ca0

SiO 2

Cr 2 o 3

P

TF

content

3.6

21

7.6

2

0.8

19.35

[0049] (2) Specifications of sulfuric acid: industrial sulfuric acid

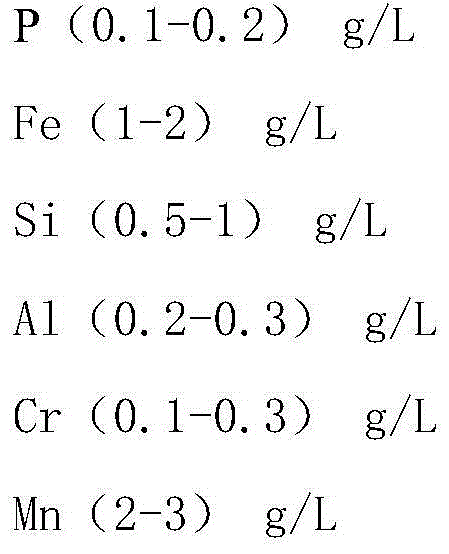

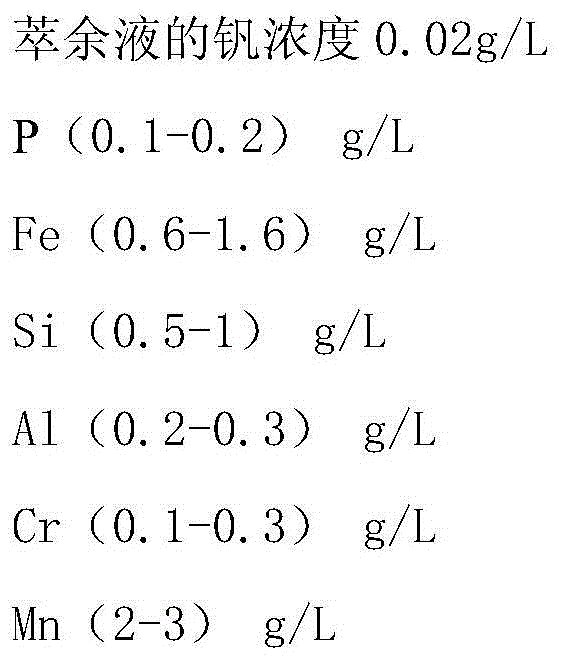

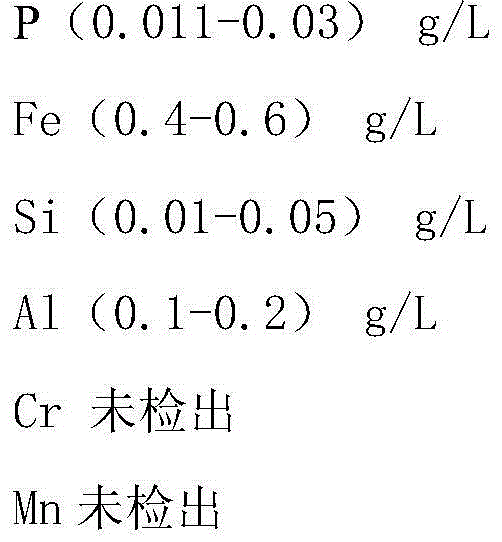

[0050]

[0051]

[0052] (3) Reducing agent: Na 2 S 2 o 5

[0053] (4) Extractant: 28% P204+6% TBP+66% sulfonated kerosene (volume ratio)

[0054] (5) stripping agent: 2mol / L sulfuric acid

[0055] (6) Vanadium precipitation agent: NH 4 HCO 3

[0056] 2. Test method

[0057] (1) Reductive acid leaching of vanadium-containing materials

[0058] Vanadium-containing material 125Kg (dry basis weight), by weight, water: vanadium-containing material=4: 1, add...

Embodiment 2

[0067] Embodiment 2 Adopt the method of the present invention to extract vanadium

[0068] Carry out according to the method in embodiment 1, difference is, the liquid vanadium content after solid-liquid separation is 4.8g / L, P (0.1g / L), Fe (1.2g / L), Si (0.6g / L) , Al (0.3g / L), Cr (0.2g / L), Mn (2.5g / L). Extractant ratio (volume ratio) 20% P204+6% TBP+74% sulfonated kerosene, the extraction rate of vanadium is 96%, the stripping rate is 98.7%, the vanadium precipitation rate is 99.7%, the purity of vanadium pentoxide: V 2 o 5 (98.2%), P (0.038%), Fe (0.42%), C (0.001%), S (0.001%), Si (0.25%).

Embodiment 3

[0069] Example 3 Using the method of the present invention to extract vanadium

[0070] Carry out according to the method in embodiment 1, difference is, the liquid vanadium content after solid-liquid separation is 4.8g / L, P (0.1g / L), Fe (1.2g / L), Si (0.6g / L) , Al (0.3g / L), Cr (0.2g / L), Mn (2.5g / L). Extractant ratio (volume ratio) 20% P507+6% TBP+74% sulfonated kerosene, the extraction rate of vanadium is 87%, the stripping rate is 98.5%, the vanadium precipitation rate is 99.7%, the purity of vanadium pentoxide: V 2 o 5 (98.05%), P (0.041%), Fe (0.51%), C (0.001%), S (0.001%), Si (0.23%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com