FBG (fiber bragg grating) based pressure sensor and application thereof

A technology of pressure sensor and optical fiber grating, which is applied in the field of pressure sensor structure, can solve problems such as crosstalk, long-period grating temperature sensitivity, and inconvenient large-scale application, and achieve the effect of easy processing, optional sensitivity and dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. The structural features of the pressure sensor of the present invention:

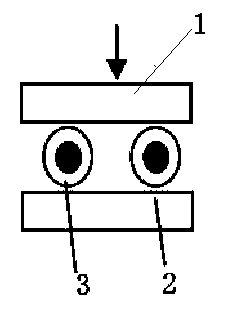

[0027] Such as figure 1 As shown, the pressure sensor consists of two metal plates 1, a supporting optical fiber 2, and an optical fiber 3 with a FBG-FP structure. The supporting optical fiber 2 and the optical fiber 3 with the FBG-FP structure are clamped between two metal plates 1 in parallel; the opposite surfaces of the two metal plates 1 are respectively smooth planes.

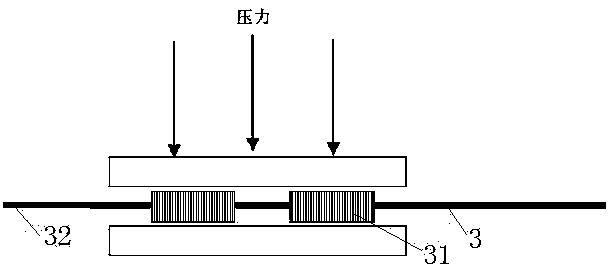

[0028] Such as figure 2 As shown, the optical fiber 3 with the FBG-FP structure is a single-mode optical fiber that includes two identical fiber gratings 31, and the two metal plates 1 completely cover the two fiber gratings in the optical fiber 3 with the FBG-FP structure. 31 serves as a Fabry-Perot structure section of the reflective surface, and the two ends 32 and 33 of the optical fiber 3 with the FBG-FP structure are respectively arranged on the outer sides of the two metal plates 1 .

[0029] Second, the charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com