Method for detecting internal crack developing of cement-based material under action of load

A technology of cement-based materials and detection methods, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of poor accuracy, low reliability, and inability to obtain intuitive data, and achieves the goal of overcoming poor accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1) Sample: Ordinary Portland cement with PO42.5 specifications (manufacturer: Yingde Nanshan Cement Factory) and standard sand produced in accordance with the national standard GB / T17671-1999 (manufacturer: Xiamen Aisiou Standard Sand Co., Ltd. ) and ordinary water, according to the ratio C:S:H=1:1:0.4, import it into a mold (self-made) with a standard diameter of 10mm and a height of 10mm, smooth the surface of the sample to form a flat surface, and vibrate , dense, forming; 24 hours to remove the formwork, and then placed in a standard curing room (relative humidity is 99%, room temperature is 21 ℃) curing for 28 days, after taking out and drying, it can be used as a cement mortar sample for testing.

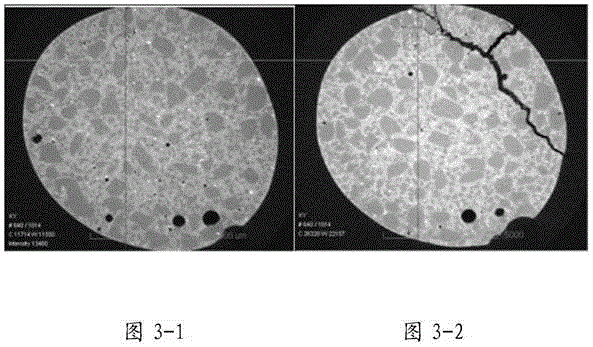

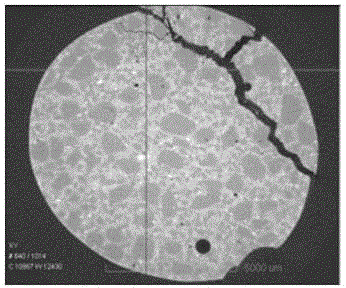

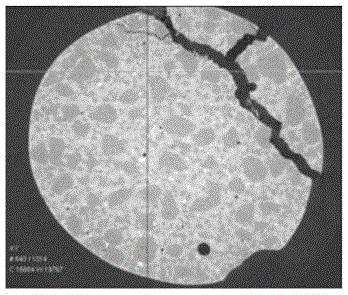

[0056] 2) Test: Load the sample with Deben X-ray tomography microscopic material testing tension and compression instrument (manufacturer: DEBEN, model: Mechanical Operation V1.0,), the equipment is equipped with an internal lifting and lowering pressure device and X Ra...

Embodiment 2

[0067] 1) Sample: Use PO42.5 ordinary Portland cement (manufacturer: Yingde Nanshan Cement Factory) and ordinary water, according to the ratio: cement: water = C: W = 1: 0.4, the standard diameter is 10mm, In a cylinder mold with a height of 10mm, the surface of the sample is smoothed to form a flat surface, and vibrated, compacted, and formed; the mold is removed after 24 hours, and then placed in a standard curing room (relative humidity is more than 95%, The room temperature is 21°C) and cured for 28 days. After taking out and drying, it can be used as a cement paste sample for testing.

[0068] 2) Test: Load the sample with the Deben X-ray tomography microscopic material testing tension and compression instrument, set the loading force as 0N and 900N, respectively pressurize in order, and then use the three-dimensional reconstruction imaging X-ray microscope to test Scan the sample and record the results.

[0069] 3) Reconstruction analysis: Use XCT-400's built-in reconst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com