Al2O3/SiON inactivation layer structure of LED (light emitting diode) chip and growth method thereof

A technology of LED chip and growth method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low density of passivation layer materials, small pinhole density, etc., achieve good compactness and reduce leakage , the effect of high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings. The LP-MOCVD used in the examples is a self-made MOCVD equipment dedicated to growing oxide materials, and the model is SCMD-600B. The plasma-enhanced chemical vapor deposition PECVD used is commercially available The model sold is Plasmalab800Plus.

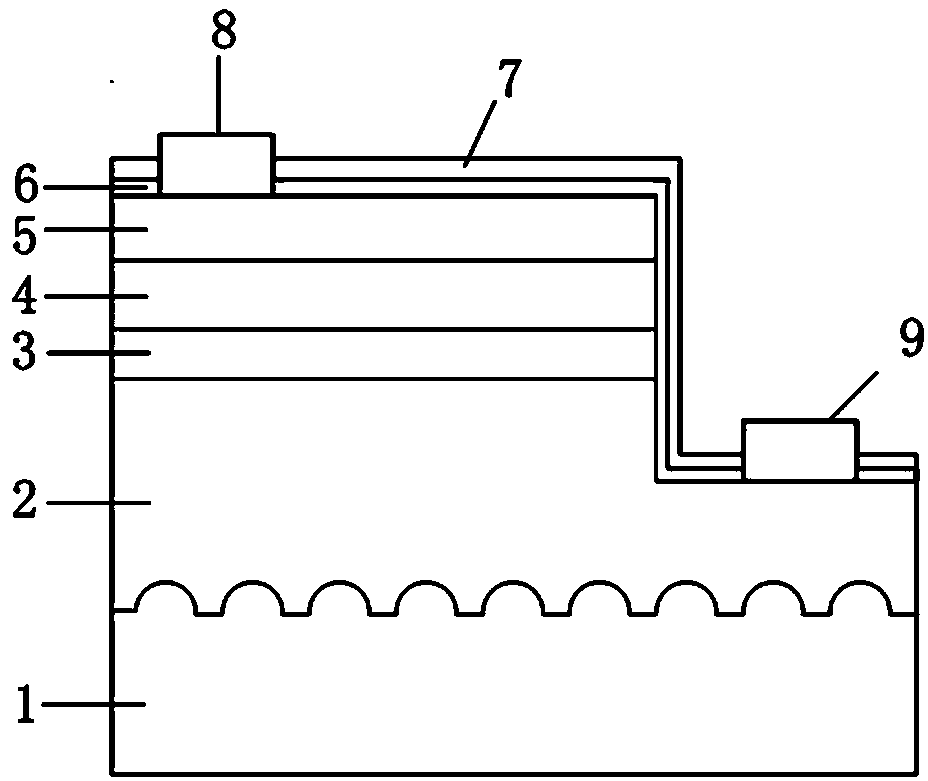

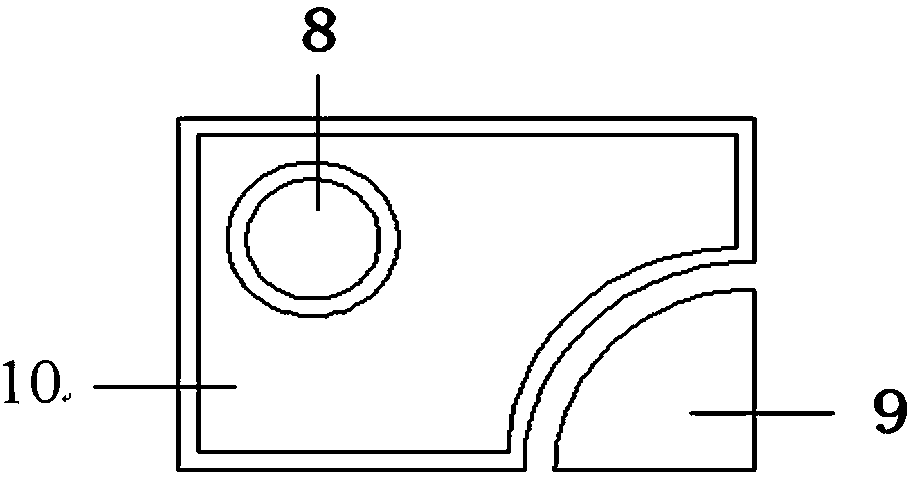

[0034] Such as figure 1 and figure 2 As shown, the Al of a kind of LED chip provided by the present invention 2 o 3 / SiON passivation layer structure, including pattern substrate 1, GaN-based epitaxial layer, ITO conductive film 5, P electrode 8, N electrode 9 and Al 2 o 3 / SiON composite layer 10, wherein the GaN-based epitaxial layer includes N-GaN2, quantum well MQW light-emitting layer 3 and P-GaN4, Al 2 o 3 / SiON composite layer 10 comprising Al 2 o 3 Passivation film 6 and SiON anti-reflection film 7. The manufacturing method of the above-mentioned embodiment is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com