Prochloraz microcapsule suspending agent and compound preparation thereof

A microcapsule suspending agent and microcapsule suspending technology, applied in the directions of insecticides, biocides, fungicides, etc., can solve the problems such as the lack of a good solution for the viscous solidification of prochloraz, so as to mask odor and reduce evaporation. Speed, the effect of suppressing volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1 Preparation of prochloraz microcapsule suspension

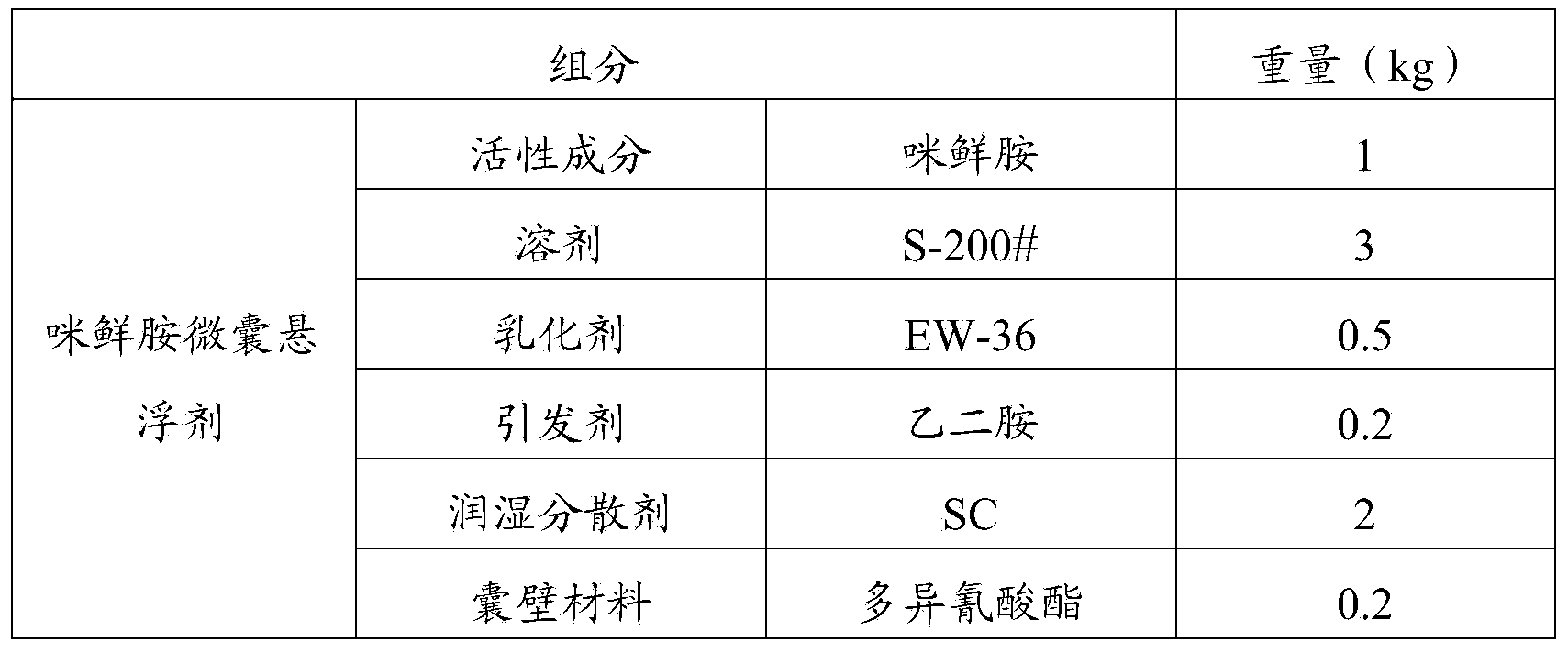

[0065] The formula of prochloraz microcapsule suspension is as shown in table 1:

[0066] Table 1 The formula of prochloraz microcapsule suspension

[0067]

[0068]

[0069] In a reaction vessel with heat preservation and stirring, the active component prochloraz is dissolved in a solvent, and after adding emulsifier, wetting and dispersing agent, water and capsule wall material and stirring evenly at a high speed (1 hour), add the initiator, change to Stir at a low speed, and gradually raise the temperature to 60°C, then stir at a low speed for 6 hours under the condition of 60°C heat preservation, to obtain a microcapsule suspension containing 1% prochloraz.

[0070] Wherein, the process parameters in the above preparation method are: the speed of high-speed stirring is controlled at 1000-1500 rpm, and the speed of low-speed stirring is controlled at 60-150 rpm.

[0071] The appearance of the pr...

Embodiment 2

[0072] Embodiment 2 Preparation of prochloraz microcapsule suspension

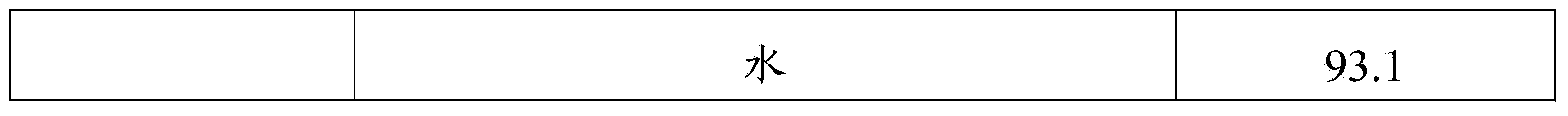

[0073] The formula of prochloraz microcapsule suspension is as shown in table 2:

[0074] Table 2 The formula of prochloraz microcapsule suspension

[0075]

[0076] In a reaction vessel with heat preservation and stirring, the active component prochloraz is dissolved in a solvent, and after adding emulsifier, wetting and dispersing agent, water and capsule wall material and stirring evenly at a high speed (1 hour), add the initiator, change to Stir at a low speed, and gradually raise the temperature to 60°C, then stir at a low speed for 6 hours under the condition of 60°C heat preservation, to obtain a microcapsule suspension containing 1% prochloraz.

[0077] Wherein, the process parameters in the above preparation method are: the speed of high-speed stirring is controlled at 1000-1500 rpm, and the speed of low-speed stirring is controlled at 60-150 rpm.

[0078] The appearance of the prepared proch...

Embodiment 3

[0079] Example 3 Preparation of prochloraz microcapsule suspension

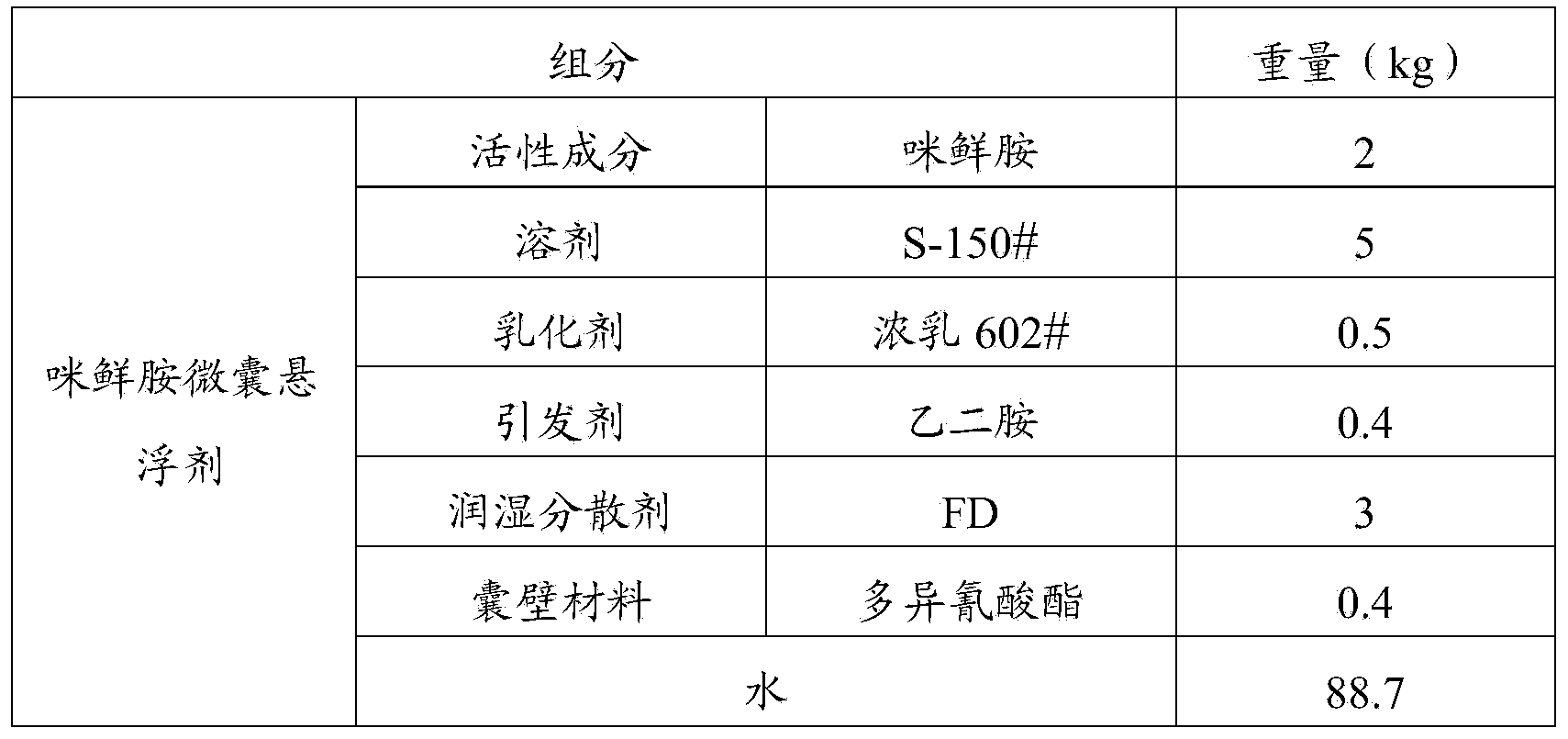

[0080] The formula of prochloraz microcapsule suspension is as shown in table 3:

[0081] Table 3 Formula of prochloraz microcapsule suspension

[0082]

[0083] In a reaction vessel with heat preservation and stirring, the active component prochloraz is dissolved in a solvent, and after adding emulsifier, wetting and dispersing agent, water and capsule wall material and stirring evenly at a high speed (1 hour), add the initiator, change to Stir at a low speed, and gradually raise the temperature to 60° C., then stir at a low speed for 6 hours at 60° C. to obtain a microcapsule suspension containing 1% prochloraz.

[0084] Wherein, the process parameters in the above preparation method are: the speed of high-speed stirring is controlled at 1000-1500 rpm, and the speed of low-speed stirring is controlled at 60-150 rpm.

[0085] The appearance of the prepared prochloraz microcapsule suspension is a flowabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com