Preparation method of fermented type gingko and peanut milk beverage

A peanut milk and fermented technology, applied in dairy products, milk substitutes, applications, etc., to achieve the effects of simple production process, saving bacteria, and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

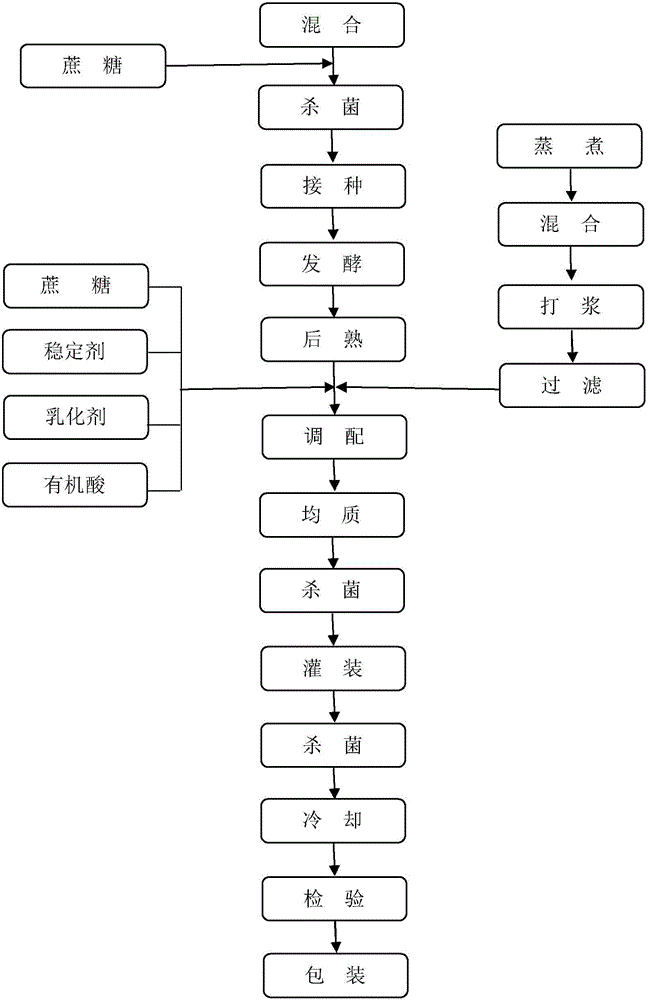

Method used

Image

Examples

Embodiment 1

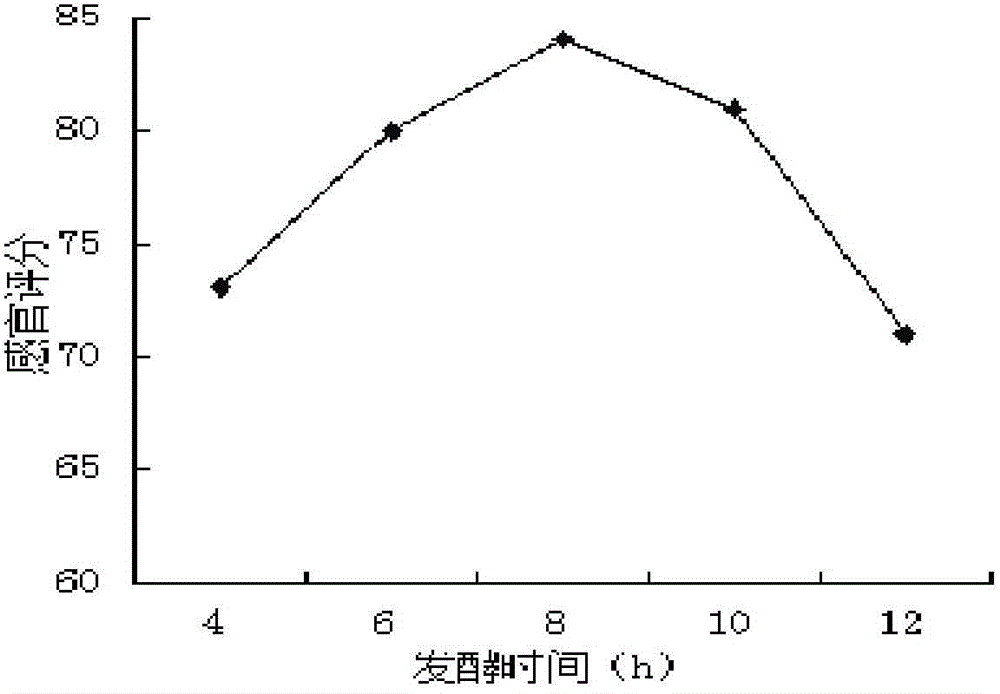

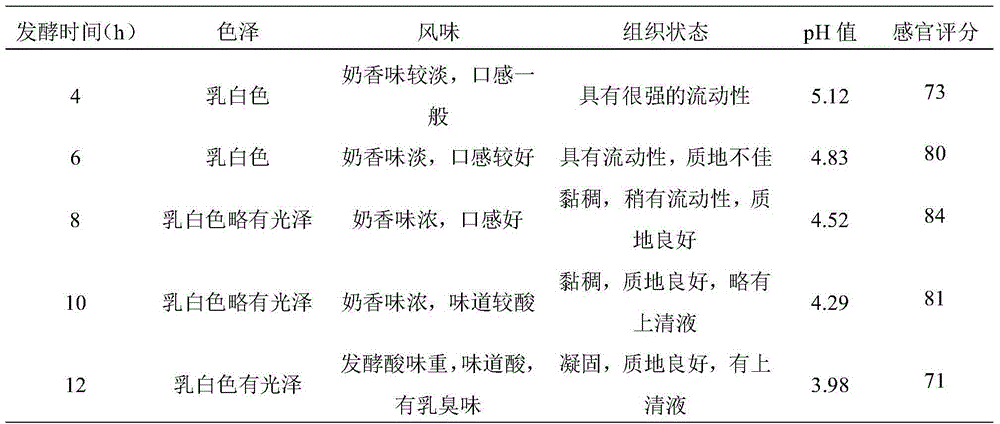

[0043] Skim milk powder and demineralized water are mixed at a mass ratio of 1:7 to make skim milk, 4g of sucrose is added, and heated to dissolve to make a mixed emulsion; a tubular sterilizer is used for instantaneous sterilization, the inlet temperature is 30°C, the sterilization temperature is 130°C, and the sterilization time is 5s, the outlet temperature is 82°C; inoculate a lactic acid bacteria strain on the medium containing MRS and activate it 1 to 2 times, inoculate it in the mixed emulsion, and inoculate 2mL of the bacterial solution, the concentration of the bacterial solution is 2.0×10 8 pieces / mL; the mixed emulsion was fermented at a constant temperature of 44°C for 6 hours, and the pH value of the fermented milk was measured to be 4.50, and after 12 hours of post-ripening; the ginkgo and peanuts were steamed for 20 minutes, and then the ginkgo and peanuts were mixed at a mass ratio of 1 :1 mixed, then be beaten with demineralized water at a mass ratio of 1:4, an...

Embodiment 2

[0045] Skim milk powder and demineralized water are mixed at a mass ratio of 1:8 to make skim milk, 5g of sucrose is added, and heated to dissolve to make a mixed emulsion; a tubular sterilizer is used for instantaneous sterilization, the inlet temperature is 40°C, the sterilization temperature is 135°C, and the sterilization time is 3s, the outlet temperature is 85°C; inoculate a lactic acid bacteria strain on the medium containing MRS to activate 1-2 times, inoculate it in the mixed emulsion, and inoculate 6mL of the bacterial solution, the concentration of the bacterial solution is 1.8×10 8 pieces / mL; the mixed emulsion was fermented for 8 hours at a constant temperature of 42°C, and the pH value of the fermented milk was measured to be 4.52, and after 12 hours of post-ripening; the ginkgo and peanuts were steamed for 40 minutes, and then the ginkgo and peanuts were mixed at a mass ratio of 1 :1 mixed, then be beaten with demineralized water in a mass ratio of 1:4, and the s...

Embodiment 3

[0047] Skim milk powder and demineralized water are mixed at a mass ratio of 1:9 to make skim milk, add 8g of sucrose, and heat to dissolve to make a mixed emulsion; use a tubular sterilizer for instant sterilization, the inlet temperature is 35°C, the sterilization temperature is 136°C, and the sterilization time is 3s, the outlet temperature is 95°C; inoculate a lactic acid bacteria strain on the medium containing MRS and activate it for 1-2 times, inoculate it in the mixed emulsion, and inoculate 4mL of the bacteria solution, the concentration of the bacteria solution is 1.4×10 8 pieces / mL; the mixed emulsion was fermented at a constant temperature of 40°C for 10 hours, and the pH value of the fermented milk was measured to be 4.60, and after 12 hours of post-ripening; the ginkgo and peanuts were steamed for 35 minutes, and then the ginkgo and peanuts were mixed at a mass ratio of 1 :1 mixed, then beating with demineralized water in a mass ratio of 1:4, and the slurry is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com