Two-effect titanium liquid concentration device and concentration process

A two-effect concentration and titanium liquid technology, applied in multi-effect evaporation, evaporation, flash evaporation, etc., can solve problems such as easy formation of calcium sulfate or gypsum solid deposits, large heat transfer area of heat exchangers, and influence on heat transfer efficiency , to achieve low cost, reduce heat transfer area, avoid fouling and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

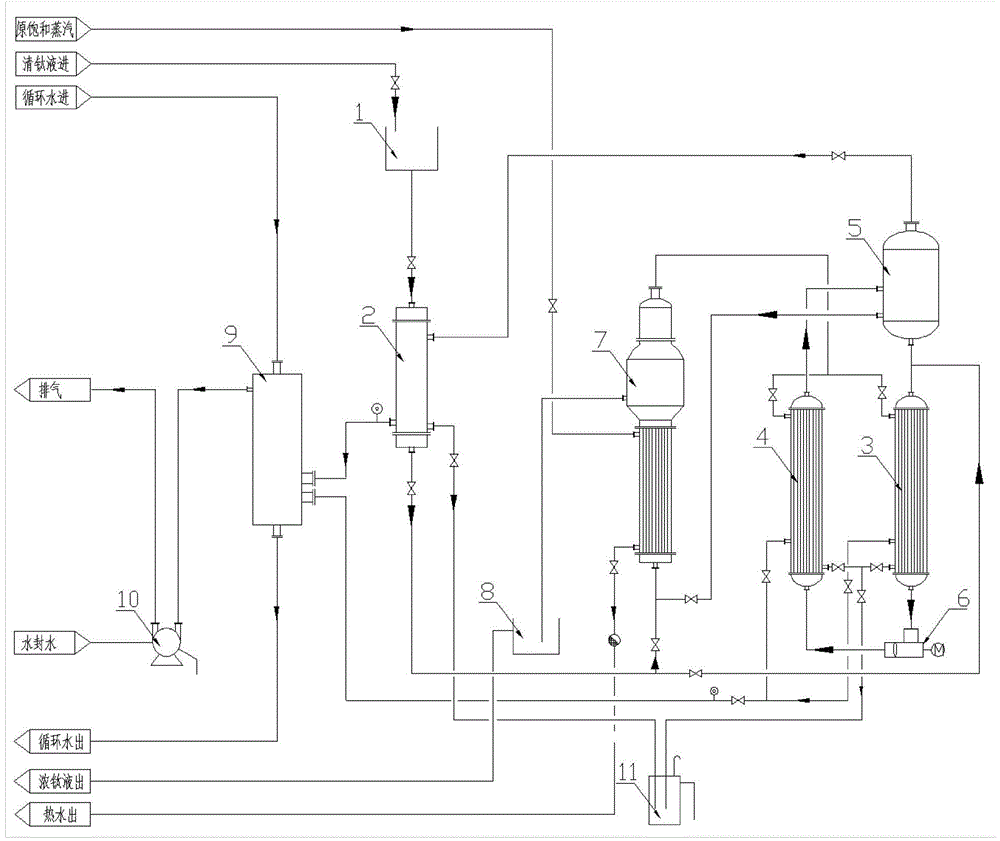

[0016] Below in conjunction with accompanying drawing, the present invention is described in detail:

[0017] Such as figure 1 As shown, the titanium liquid two-effect concentration device of the present invention includes a high-level liquid storage tank 1, a preheater 2, a primary heat exchanger 3, a secondary heat exchanger 4, a flash tank 5, a circulation pump 6, and a thin film evaporator 7. Concentrated liquid storage tank 8, atmospheric condenser 9, vacuum pump 10 and liquid seal pool 11. The concentration process of the concentration device of the present invention is as follows: the dilute titanium liquid enters the preheater 2 from the high-level liquid storage tank 1 to preheat, and the heat source of the preheater is the secondary steam flashed out of the flash tank 5 . Then enter the forced circulation evaporation system, the forced circulation evaporation system is composed of primary heat exchanger 3, secondary heat exchanger 4, circulation pump 6, circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com