Light-weight bullet-proof glass and preparation method thereof

A bullet-proof glass, lightweight technology, applied in the direction of chemical instruments and methods, glass/slag layered products, adhesive types, etc., can solve the problems of bullet-proof glass monomer weight, product unit weight, low light transmittance, etc., to achieve Excellent anti-penetration performance, good impact resistance effect, high light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

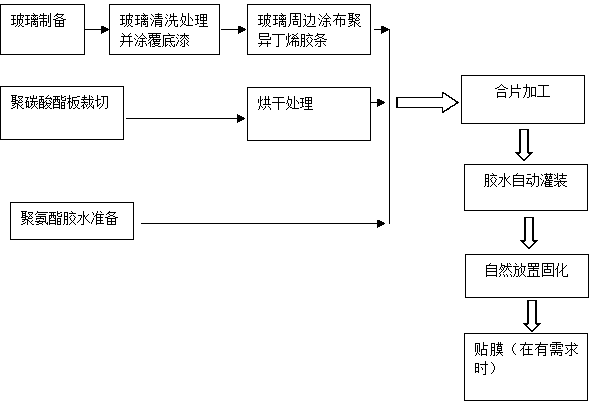

[0034] Such as figure 1 As shown, the lightweight bulletproof glass is bonded with polyurethane glue between the glass and the polycarbonate plate. The polyurethane glue is a two-component polyurethane glue, which includes: A component: polyol polymer; B component: isocyanate, The volume ratio of the two components A:B=100:65. Among them, the polyol polymer is 80% silyl polyether, 20% butanediol; the isocyanate is 3-trimethyl-5-isocyanato-1-isocyanate (base) methylcyclohexane 50% %, polyisocyanate 50%. One side of the glass bonded with polyurethane glue is coated with a layer of primer, and the primer is composed of 72% distilled water, 20% silane coupling agent, and 8% isopropanol.

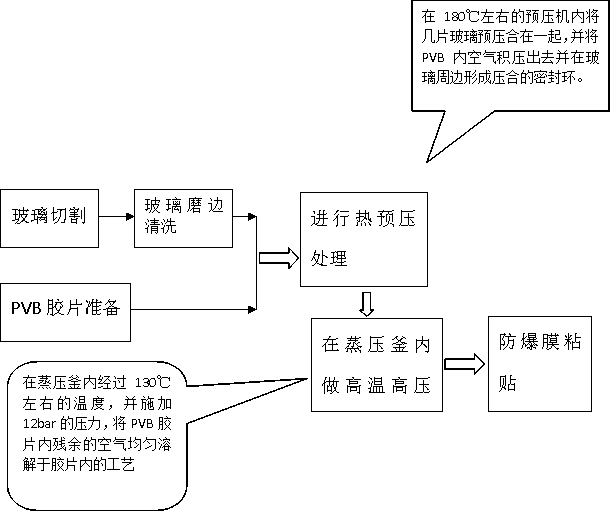

[0035] The preparation method of lightweight bulletproof glass is:

[0036] First cut the PC board into the required size, then dry it at 40~60°C for 12 hours, and then place it in an environment with a relative humidity of 18~23°C and 50%RH for use; cut and grind the glass After edge molding...

Embodiment 2

[0038] Lightweight bulletproof glass, glass and polycarbonate panels are bonded with polyurethane glue, the polyurethane glue is a two-component polyurethane glue, which includes: A component: polyol polymer; B component: isocyanate, two components The volume ratio of A:B=100:70. Among them, the polyol polymer is 85% silyl polyether, butanediol 15%; the isocyanate is 3-trimethyl-5-isocyanato-1-isocyanate (base) methylcyclohexane 70 %, polyisocyanate 30%. One layer of primer is coated on one side of the glass bonded with polyurethane glue, and the primer is composed of 80% distilled water, 15% silane coupling agent, and 5% isopropanol.

[0039] Its preparation method is with embodiment 1.

Embodiment 3

[0041] Lightweight bulletproof glass, glass and polycarbonate panels are bonded with polyurethane glue, the polyurethane glue is a two-component polyurethane glue, which includes: A component: polyol polymer; B component: isocyanate, two components The volume ratio of A:B=100:75. Among them, the polyol polymer is 90% of silyl polyether, 10% of butanediol; the isocyanate is 3-trimethyl-5-isocyanato-1-isocyanate (base) methylcyclohexane %, Polyisocyanate 25%. One layer of primer is coated on one side of the glass bonded with polyurethane glue, and the primer consists of 74% distilled water, 20% silane coupling agent, and 6% isopropanol.

[0042] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com