Concrete with improved construction performance and preparation method thereof

A technology of construction performance and concrete, which is applied in the field of building materials and its preparation, and can solve problems such as short setting time and long setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

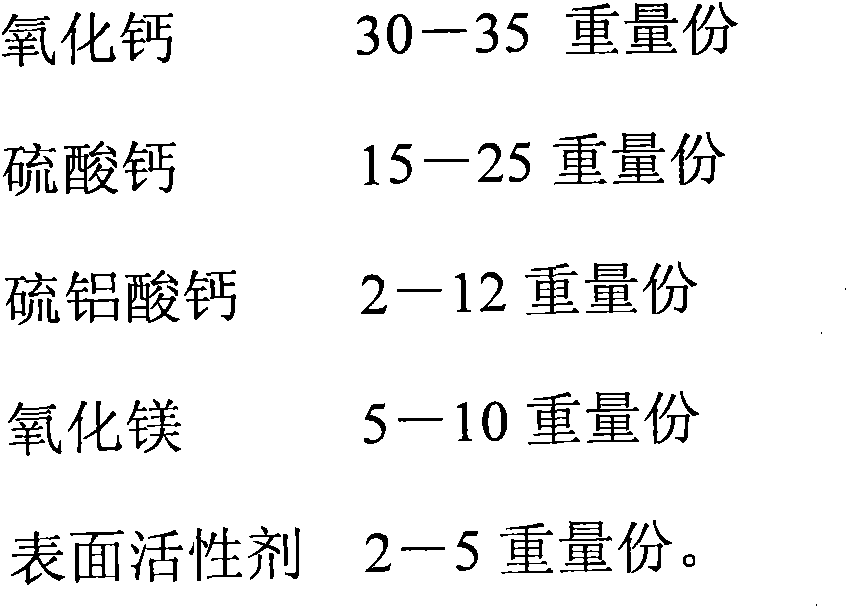

Method used

Image

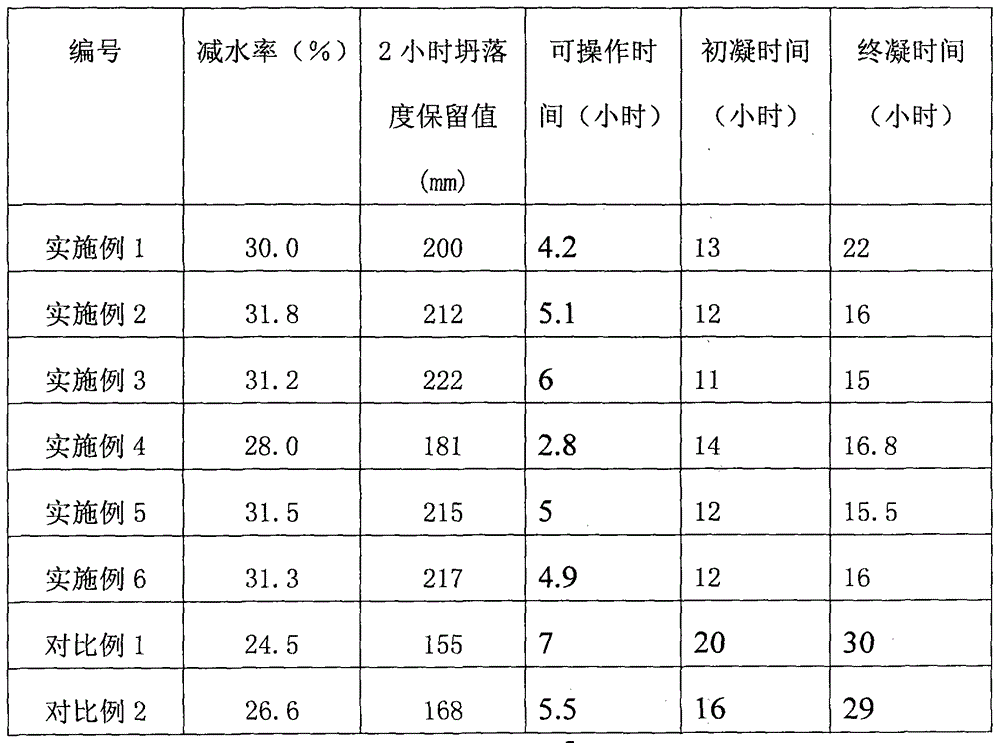

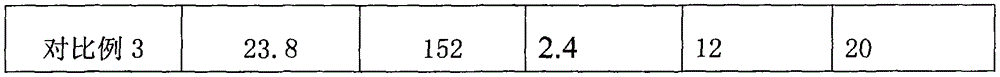

Examples

preparation Embodiment 1-1

[0029] 180 grams of methyl vinyl polyoxyethylene ether (molecular weight is 1000-2000) and 122 grams of soft water are dropped into the reactor, the temperature is raised to 35 ° C, and then 0.5 gram of dicumyl peroxide is added to make the bottom material;

[0030] Add 2.5 grams of dipolycyanamide, 15 grams of acrylic acid, 60 grams of demineralized water and 0.45 grams of mercaptopropionic acid in the batching kettle to make A material, which is pumped to the metering tank for subsequent use.

[0031] Add 105 grams of demineralized water and 0.1 gram of sodium bisulfite formaldehyde in another batching still, be made into B material, be pumped to metering tank, standby.

[0032] Add material A and material B dropwise to the bottom material at a constant speed, the dropping time of material A is 180 minutes, and the delivery time of material B is 210 minutes. After the dropping is completed, keep warm for 90 minutes. Subsequently, 9 g of 32% aqueous sodium hydroxide solution ...

preparation Embodiment 1-2

[0034] Other steps are the same as in Example 1-1, except that dipolycyanamide is replaced with oleylamine. The yield was 97%.

preparation Embodiment 1-3

[0036] Other steps are the same as in Example 1-1, except that oleoylethanolamine is used instead of dicyandiamide. The yield was 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com