Preparation method of plasticizer triethylene glycol di-2-ethylhexoate

A technology of triethylene glycol and isooctanoate, which is applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of low content and yield of triethylene glycol diisooctanoate. and other problems, to achieve the effect of reducing product yield, improving ester content and yield, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

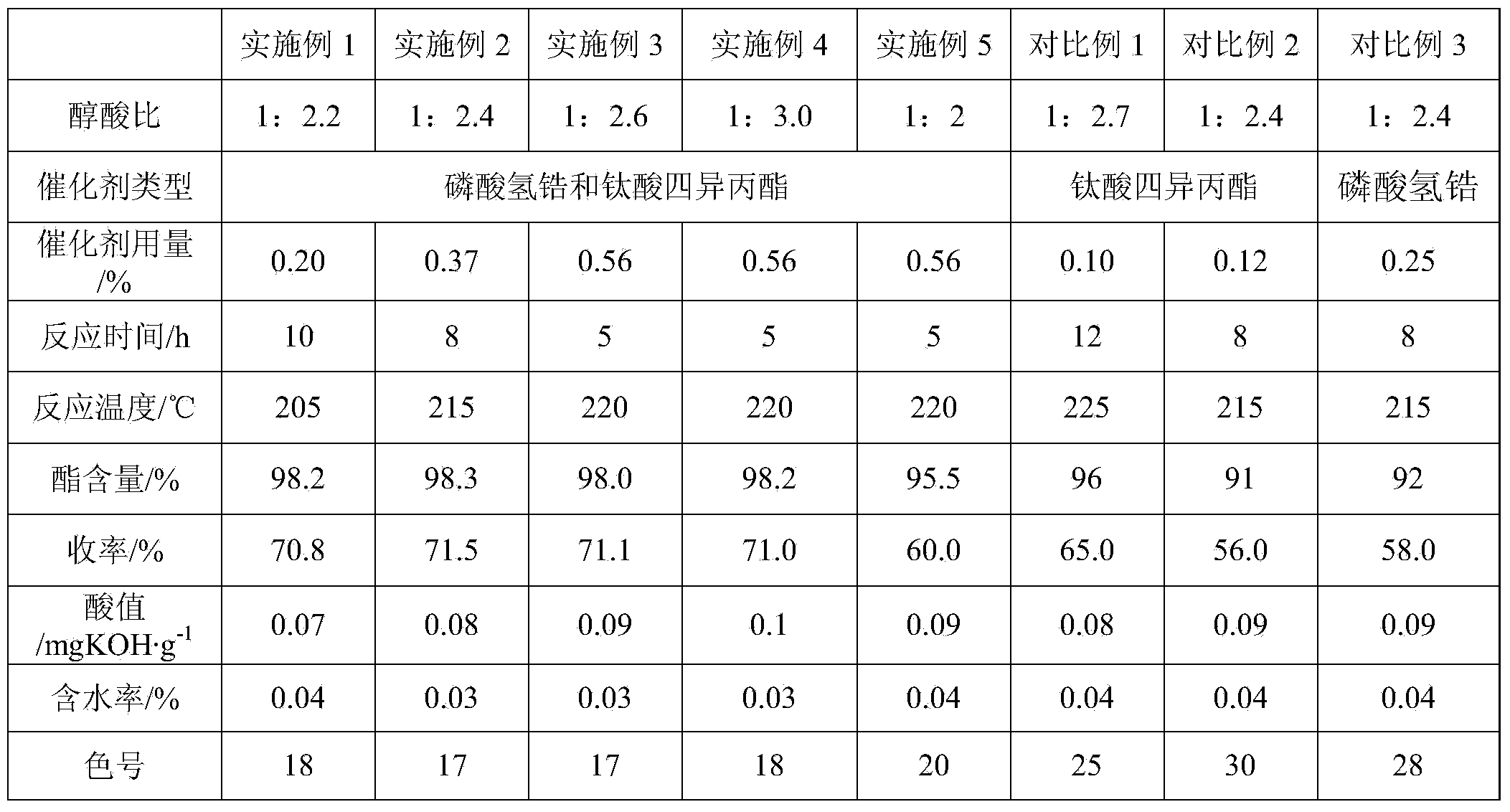

Examples

Embodiment 1

[0025] Weigh 100g triethylene glycol, 220g isooctanoic acid, 1.22g gac, 0.58gN,N-dimethylformamide, 0.32g zirconium hydrogen phosphate (crystalline zirconium hydrogen phosphate [α-Zr(HPO 4 ) 2 ·H 2 [0], the same below) and 0.32g of tetraisopropyl titanate were added to a three-neck flask (800ml) equipped with a thermometer, a water separator and a reflux condenser, stirred and heated to reflux, and heated to 205°C for esterification reaction for 10 hours Finally, no water belt was observed in the water separator, and the esterification reaction was completed, and unreacted excess isooctanoic acid was recovered by distillation. The reaction solution of the esterification reaction is filtered to obtain the crude triethylene glycol diisocaprylate liquid, and the crude triethylene glycol diisocaprylate liquid is neutralized and washed until the acid value of the crude product is lower than 0.1mgKOH g -1 . The crude triethylene glycol diisocaprylate washed with neutralization wa...

Embodiment 2

[0027] Weigh 100g of triethylene glycol, 240g of isooctanoic acid, 1.36g of activated carbon, 0.68g of N,N-dimethylformamide, 0.85g of zirconium hydrogen phosphate and 0.41g of tetraisopropyl titanate, add a thermometer and water separator In a three-necked flask (800ml) with a reflux condenser, stir and heat to reflux, and heat up to 215°C for esterification for 8 hours. After 8 hours of esterification, no water bands are observed in the water separator. bitter. The reaction solution of the esterification reaction is filtered to obtain the crude triethylene glycol diisocaprylate liquid, and the crude triethylene glycol diisocaprylate liquid is neutralized and washed until the acid value of the crude product is lower than 0.1mgKOH g -1 . The crude triethylene glycol diisocaprylate washed with neutralization water was dehydrated at a vacuum degree of 5 kPa and a temperature of 120° C. for 2 hours to obtain 221.69 g of a crude triethylene glycol diisocaprylate. Add 0.22g of ac...

Embodiment 3

[0029] Weigh 100g of triethylene glycol, 260g of isooctanoic acid, 1.62g of activated carbon, 0.82g of N,N-dimethylformamide, 1.44g of zirconium hydrogen phosphate and 0.57g of tetraisopropyl titanate, add a thermometer, water separator and In the three-necked flask (800ml) of the reflux condenser, stir and heat to reflux, and raise the temperature to 220°C for 5 hours of esterification reaction. bitter. The reaction solution of the esterification reaction is filtered to obtain the crude triethylene glycol diisocaprylate liquid, and the crude triethylene glycol diisocaprylate liquid is neutralized and washed until the acid value of the crude product is lower than 0.1mgKOH g -1 . The crude triethylene glycol diisocaprylate washed with neutralized water was dehydrated at a vacuum degree of 5 kPa and a temperature of 120° C. for 2 hours to obtain 233.32 g of a crude triethylene glycol diisocaprylate. Add 0.23g of activated carbon to the dehydrated crude triethylene glycol diiso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com