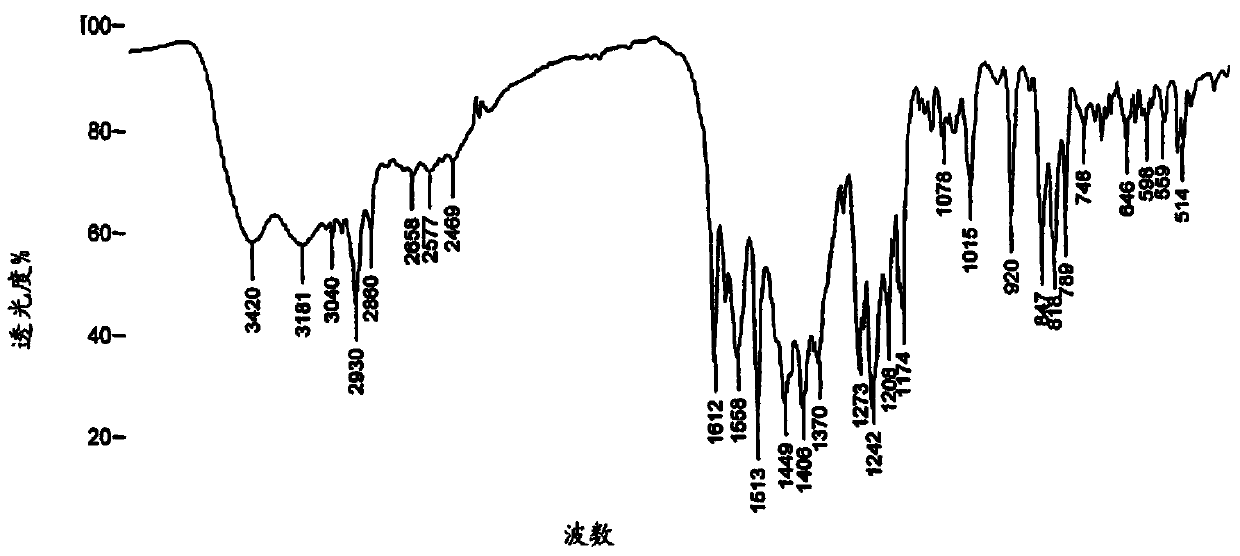

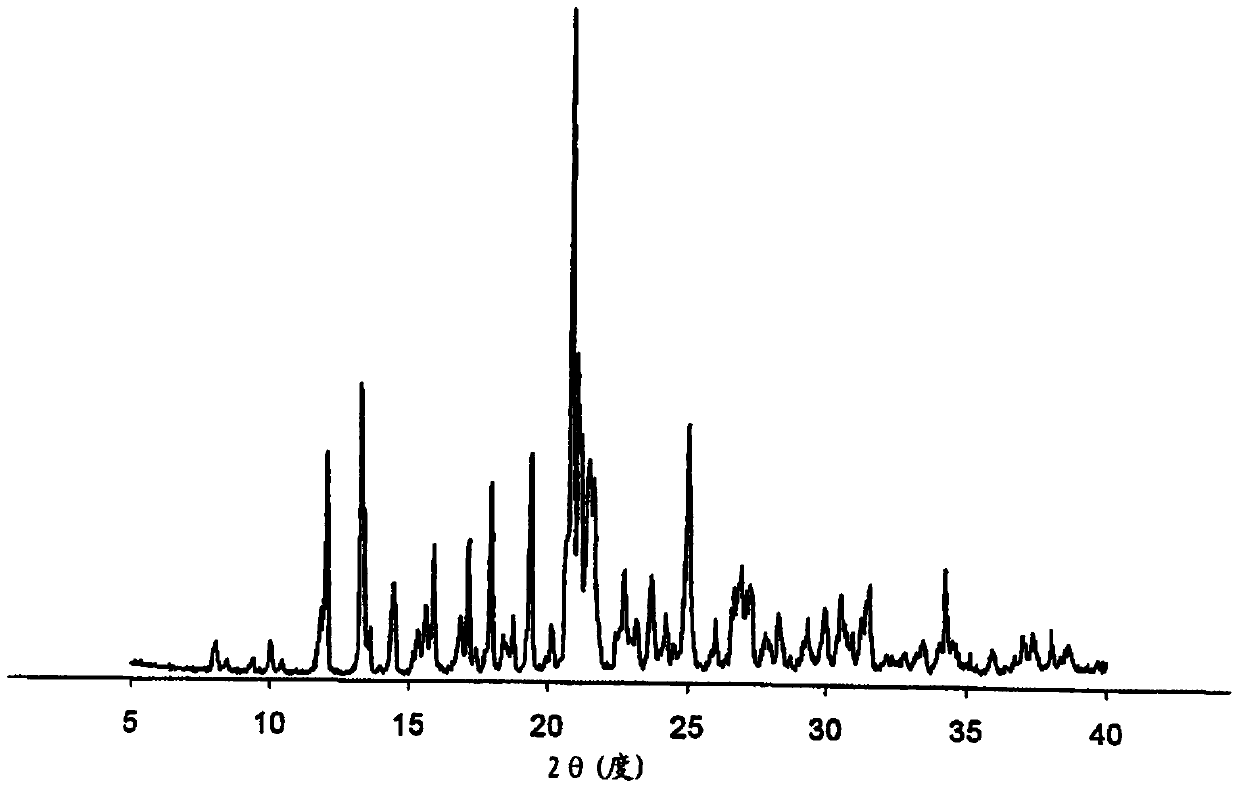

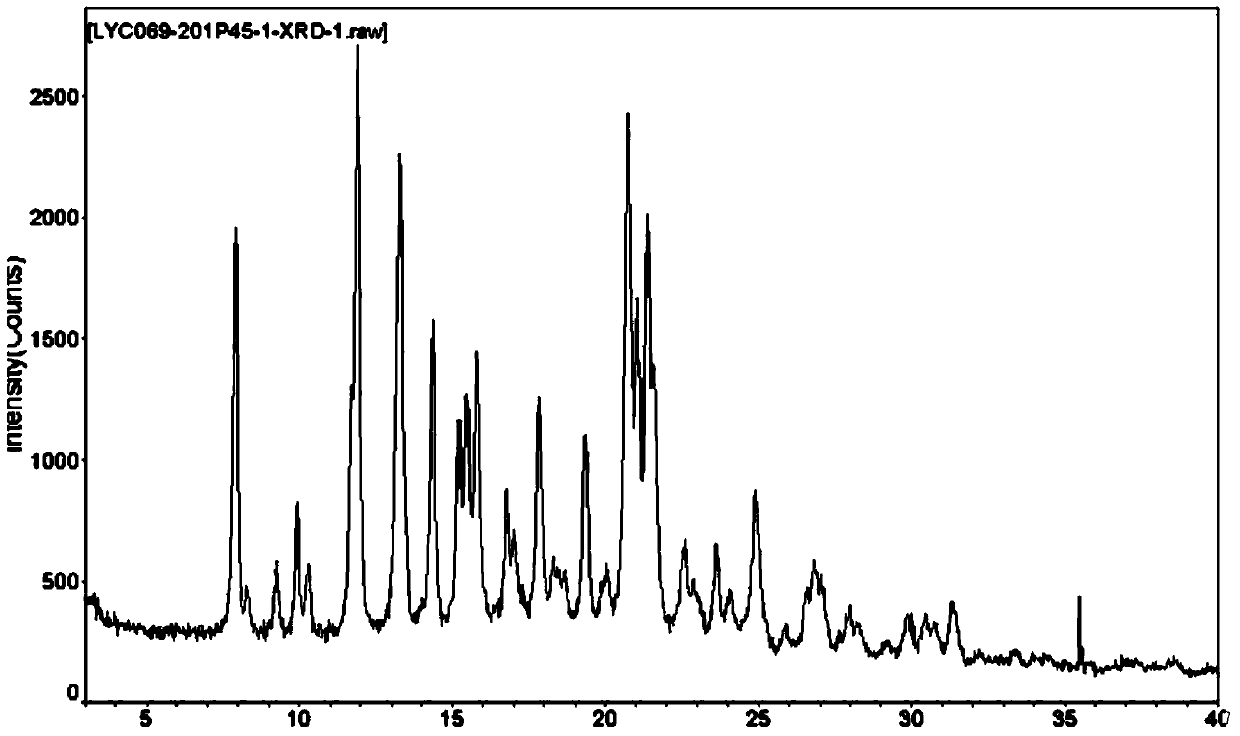

Preparation method of bazedoxifene acetate polycrystalline type B

A technology of bazedoxifene acetate and its polymorphic forms, which is applied in the field of pharmacy, can solve the problems of no public preparation of polymorphic form B, no detailed description of the salt-forming process, and unsuitability for large-scale production, so as to shorten the production cycle and cost Salt crystallization time is short, suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 4.0g of bazedoxifene free base and 12.0g of methyl tert-butyl ether into a 250mL three-neck flask, control the temperature and stir to dissolve at 18°C, add 1.1g (3eq) of glacial acetic acid and continue to insulate and stir for 1 hour, then cool down to Suction filtration at 10°C, and the filter cake was washed with an appropriate amount of methyl tert-butyl ether to obtain bazedoxifene acetate polymorph B solid. The solid was vacuum-dried at 35°C to obtain 3.19 g of bazedoxifene acetate, with a yield of 98.0%.

Embodiment 2

[0036] Weigh 4.0g of bazedoxifene free base and 40.0g of methyl tert-butyl ether in a 250mL three-neck flask, stir and dissolve under temperature control at 27°C, add 0.37g (1eq) of glacial acetic acid and continue to insulate and stir for 2 hours before cooling down to Suction filtration at 20°C, and the filter cake was washed with an appropriate amount of methyl tert-butyl ether to obtain bazedoxifene acetate polymorph B solid. The solid was vacuum-dried at 40°C to obtain 3.16 g of bazedoxifene acetate, with a yield of 97.0%.

Embodiment 3

[0038] Weigh 4.0g of bazedoxifene free base and 160.0g of methyl tert-butyl ether in a 250mL three-necked flask, control the temperature and stir to dissolve at 35°C, add 0.73g (2eq) of glacial acetic acid and continue to insulate and stir for 3 hours before cooling down to Suction filtration at 10°C, and the filter cake was washed with an appropriate amount of 4-methyl-2-pentanone to obtain bazedoxifene acetate polymorph B solid. The solid was vacuum-dried at 40°C to obtain 3.18 g of bazedoxifene acetate, with a yield of 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com