Rubber composite modified by carbon nano tubes and graphene jointly

A carbon nanotube and modified rubber technology, which is applied in the field of rubber composite materials, can solve the problems of improved electrical conductivity, low friction resistance of rubber, poor heat dissipation, etc., achieve good wear resistance, improve electrical conductivity, and improve antistatic and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

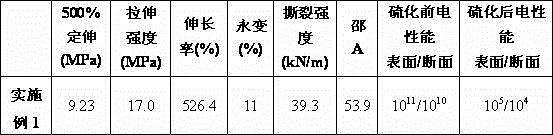

Embodiment 1

[0021] The rubber composite material modified jointly by carbon nanotubes and graphene is composed of 0.005 parts by weight of graphene, 0.01 parts of carbon nanotubes, 2 parts of fillers, and 50 parts of natural rubber.

[0022] The rubber composite material modified by carbon nanotubes and graphene is mixed in proportion and placed on a two-roll mill at 30 to 40 o Roll pressing at C for 58 minutes; press with an electric heating flat vulcanizer, and the hot pressing temperature is 80-100 o C, 10 minutes, cold pressing for 20 minutes to obtain a mixed compound of graphene, carbon nanotubes and rubber; the mixed compound of carbon nanotubes and rubber is at a rotor speed of 45 to 60 rpm and a temperature of 50 to 60 o React in the torque rheometer of C for 2 to 5 minutes; add stearic acid, anti-aging agent, accelerator and sulfur in turn and mix for 4 to 8 minutes to obtain the mixed rubber; place the obtained mixed rubber in two places at room temperature Supplementary mixin...

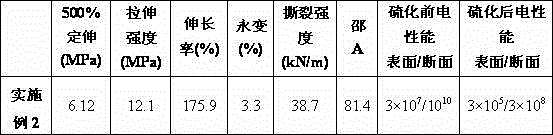

Embodiment 2

[0026] The rubber composite material modified jointly by carbon nanotubes and graphene is composed of 0.005 parts by weight of graphene, 0.01 parts of carbon nanotubes, 2 parts of fillers, and 50 parts of nitrile rubber.

[0027] The rubber composite material modified by carbon nanotubes and graphene is mixed in proportion and placed on a two-roll mill at 30 to 40 o Roll pressing at C for 58 minutes; press with an electric heating flat vulcanizer, and the hot pressing temperature is 80-100 o C, 10 minutes, cold pressing for 20 minutes to obtain a mixed compound of graphene, carbon nanotubes and rubber; the mixed compound of carbon nanotubes and rubber is at a rotor speed of 45 to 60 rpm and a temperature of 50 to 60 o React in the torque rheometer of C for 2 to 5 minutes; add stearic acid, anti-aging agent, accelerator and sulfur in turn and mix for 4 to 8 minutes to obtain the mixed rubber; place the obtained mixed rubber in two places at room temperature Supplementary mixin...

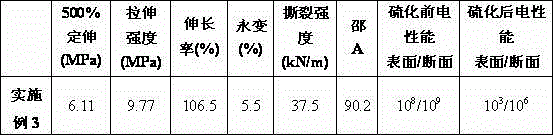

Embodiment 3

[0031] The rubber composite material modified jointly by carbon nanotubes and graphene is composed of 0.005 parts by weight of graphene, 0.01 parts of carbon nanotubes, 2 parts of fillers, and 50 parts of styrene-butadiene rubber.

[0032] The rubber composite material modified by carbon nanotubes and graphene is mixed in proportion and placed on a two-roll mill at 30 to 40 o Roll pressing at C for 58 minutes; press with an electric heating flat vulcanizer, and the hot pressing temperature is 80-100 o C, 10 minutes, cold pressing for 20 minutes to obtain a mixed compound of graphene, carbon nanotubes and rubber; the mixed compound of carbon nanotubes and rubber is at a rotor speed of 45 to 60 rpm and a temperature of 50 to 60 o React in the torque rheometer of C for 2 to 5 minutes; add stearic acid, anti-aging agent, accelerator and sulfur in turn and mix for 4 to 8 minutes to obtain the mixed rubber; place the obtained mixed rubber in two places at room temperature Supplemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com