Medical antibacterial material and preparation method thereof

A technology of antibacterial materials and antioxidants, applied in the field of medical antibacterial materials and their preparation, can solve problems such as unsatisfactory antibacterial performance, and achieve the effect of good comprehensive performance and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

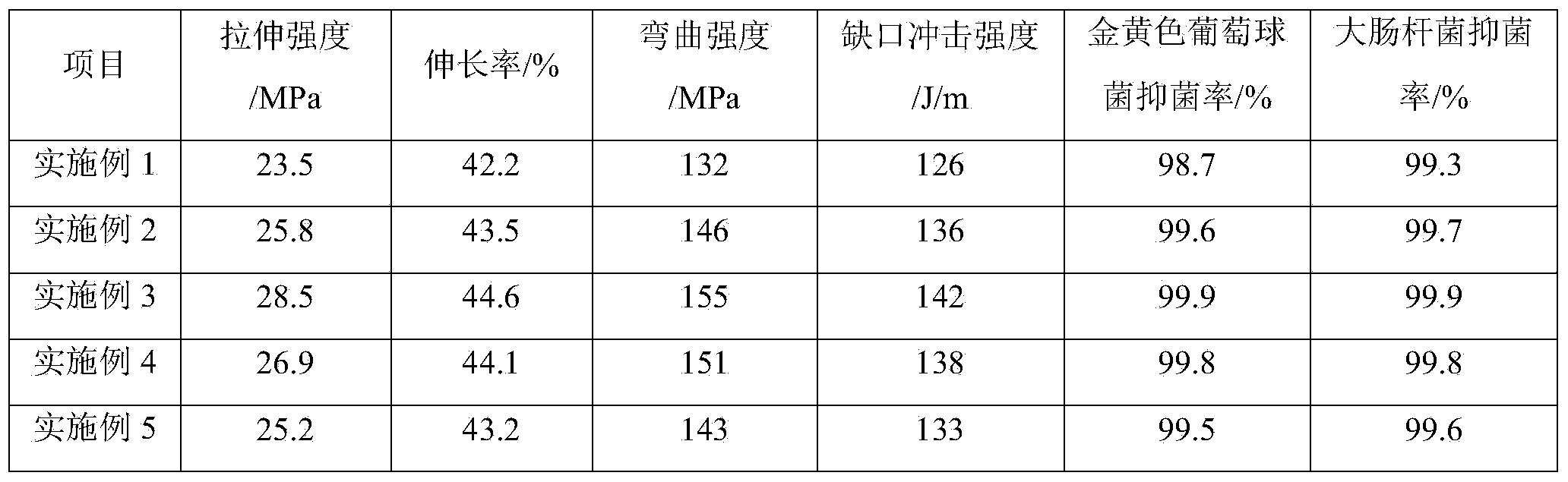

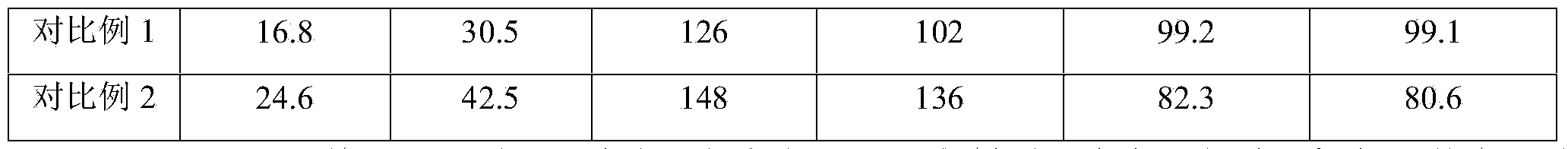

Examples

Embodiment 1

[0024] A medical antibacterial material, comprising by weight components: 65 parts of PE, 0.8 part of antioxidant CA, 0.8 part of co-antioxidant DLTP, 3 parts of butyl acetate, 1 part of sodium carbonate, 5 parts of tall oil fatty acid, 5 parts of lauryl betaine, 0.5 part of sodium tripolyphosphate, 0.8 part of sodium xylene sulfonate, 1 part of dodecyl dimethyl benzyl ammonium chloride.

[0025] The preparation method of above-mentioned medical antibacterial material, comprises the following steps:

[0026] Step 1: Add PE, butyl acetate and tall oil fatty acid to the reaction kettle, add sodium carbonate, lauryl betaine, sodium tripolyphosphate, sodium xylene sulfonate and dodecyl dimethyl benzyl chloride Dissolve ammonium chloride in 20 parts of water, then add it into the reaction kettle, stir and mix evenly under the condition of 50°C, the stirring speed of stirring and mixing evenly is 150 rpm, the mixing time is 20 minutes, and then under the vacuum degree of 0.02MPa Ra...

Embodiment 2

[0030] A medical antibacterial material, comprising by weight components: 70 parts of PE, 1 part of antioxidant CA, 1 part of co-antioxidant DLTP, 6 parts of butyl acetate, 2 parts of sodium carbonate, 7 parts of tall oil fatty acid, 6 parts of lauryl betaine, 0.6 part of sodium tripolyphosphate, 1.2 parts of sodium xylene sulfonate, 1 part of dodecyl dimethyl benzyl ammonium chloride.

[0031] The preparation method of above-mentioned medical antibacterial material, comprises the following steps:

[0032] Step 1: Add PE, butyl acetate and tall oil fatty acid to the reaction kettle, add sodium carbonate, lauryl betaine, sodium tripolyphosphate, sodium xylene sulfonate and dodecyl dimethyl benzyl chloride Dissolve ammonium chloride in 22 parts of water, then add it into the reaction kettle, stir and mix evenly at 53°C, the stirring speed of stirring and mixing is 160 rpm, the mixing time is 25 minutes, and then under the vacuum degree of 0.03MPa Raise the temperature to 82°C, ...

Embodiment 3

[0035] A medical antibacterial material, comprising by weight components: 75 parts of PE, 1.2 parts of antioxidant CA, 1.2 parts of co-antioxidant DLTP, 7 parts of butyl acetate, 3 parts of sodium carbonate, 8 parts of tall oil fatty acid, 7 parts of lauryl betaine, 0.7 parts of sodium tripolyphosphate, 1.4 parts of sodium xylene sulfonate, 2 parts of dodecyl dimethyl benzyl ammonium chloride.

[0036] The preparation method of above-mentioned medical antibacterial material, comprises the following steps:

[0037] Step 1: Add PE, butyl acetate and tall oil fatty acid to the reaction kettle, add sodium carbonate, lauryl betaine, sodium tripolyphosphate, sodium xylene sulfonate and dodecyl dimethyl benzyl chloride Dissolve ammonium chloride in 26 parts of water, then add it to the reaction kettle, stir and mix evenly at 55°C, wherein the stirring speed of stirring and mixing is 180 rpm, the mixing time is 30 minutes, and then under the vacuum degree of 0.04MPa Raise the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com