Method for preparing oil fracturing proppant from high-aluminum fly ash

A high-alumina fly ash and fracturing proppant technology, which is applied in chemical instruments and methods, earthwork drilling, and drilling compositions, can solve the problems of high production cost and high density of ceramsite proppant, and achieve The effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

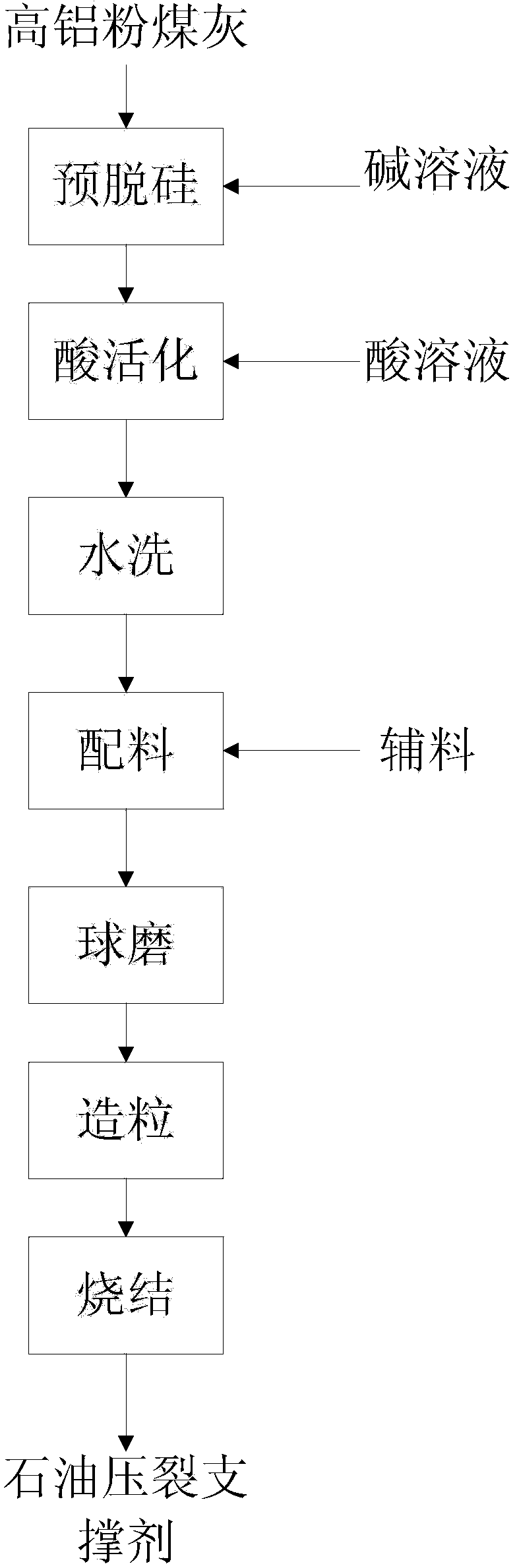

Method used

Image

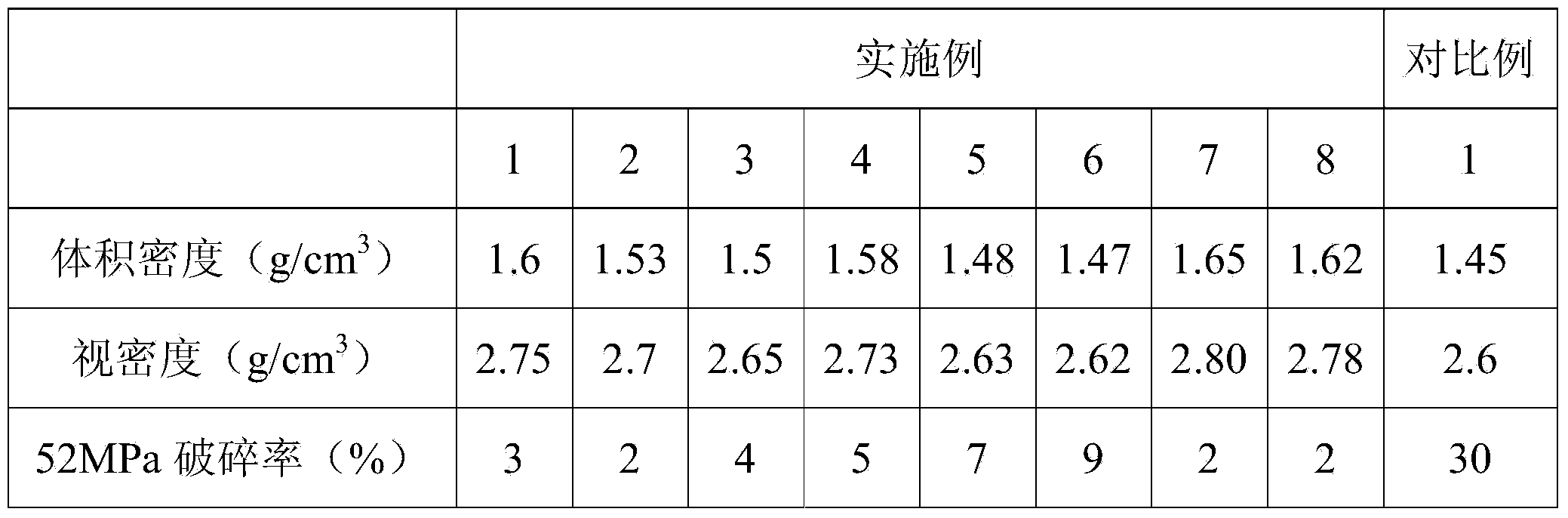

Examples

Embodiment 1

[0065] Pre-desilication reaction: put high-aluminum fly ash in 20% sodium hydroxide solution, the liquid-solid ratio is 4:1, heat up to 120°C, and stir at a stirring rate of 300r / min for 3h to react.

[0066] Acid activation reaction: filter and wash the fly ash after the pre-desilication reaction, put it in 10% hydrochloric acid solution, the liquid-solid ratio is 3:1, heat up to 75°C, and stir at a stirring rate of 300r / min for 2h to react .

[0067] After pre-desiliconization and acid activation reaction, washing and filtering, the high-alumina fly ash content is obtained: 65.8% of aluminum oxide, 31.4% of silicon oxide, 0.4% of iron oxide, wherein 10% of the total material mass is added as an auxiliary material (wherein the auxiliary material composition is Clay 30%, manganese ore powder 70%) were mixed evenly, and wet ball milled for 5 hours. The average particle size of the material after ball milling was 15 μm. After ball milling, the material was filtered and put into ...

Embodiment 2

[0069] Pre-desilication reaction: put high-aluminum fly ash in 15% sodium hydroxide solution, the liquid-solid ratio is 3:1, heat up to 110°C, and stir at a stirring rate of 400r / min for 2h to react.

[0070] Acid activation reaction: filter the fly ash after the pre-desiliconization reaction, wash it with water, put it in 15% hydrochloric acid solution, the liquid-solid ratio is 3:1, heat up to 65°C, and stir at a stirring rate of 300r / min for 2h to react .

[0071] After pre-desilication and acid activation reaction, washing and filtering, the high-alumina fly ash content is obtained: 60.5% of aluminum oxide, 35.4% of silicon oxide, 1.3% of iron oxide, wherein 6% of the total material mass is added as an auxiliary material (wherein the auxiliary material composition is 20% clay, 80% manganese ore powder) were mixed evenly, and wet ball milled for 3 hours. The average particle size of the material after ball milling was 23 μm. After ball milling, the material was filtered and...

Embodiment 3

[0073] Pre-desilication reaction: put high-alumina fly ash in 20% sodium hydroxide solution with a liquid-solid ratio of 4:1, heat up to 100°C, and stir at a stirring rate of 300r / min for 1h to react.

[0074] Acid activation reaction: filter and wash the fly ash after the pre-desiliconization reaction, put it in 10% hydrochloric acid solution, the liquid-solid ratio is 4:1, heat up to 70°C, and stir at a stirring rate of 400r / min for 1h to react .

[0075] After pre-desilication and acid activation reaction, washing and filtering, the high-alumina fly ash content is obtained: 57.6% of aluminum oxide, 38.2% of silicon oxide, 1.1% of iron oxide, wherein 6% of the total material mass is added as an auxiliary material (wherein the auxiliary material composition is Clay 10%, manganese ore powder 90%) were mixed evenly, and wet ball milled for 6 hours. The average particle size of the material after ball milling was 12 μm. After ball milling, the material was filtered and dried in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com