A new type of blended wool and its mercerizing process

A wool, a new type of technology, applied in the treatment of textile materials, mercerizing, mercerizing of yarn/thread/filament, etc., can solve the problems of high price and limited use of pure wool, and achieve omission of dyeing process, reduction of pollution, contact large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

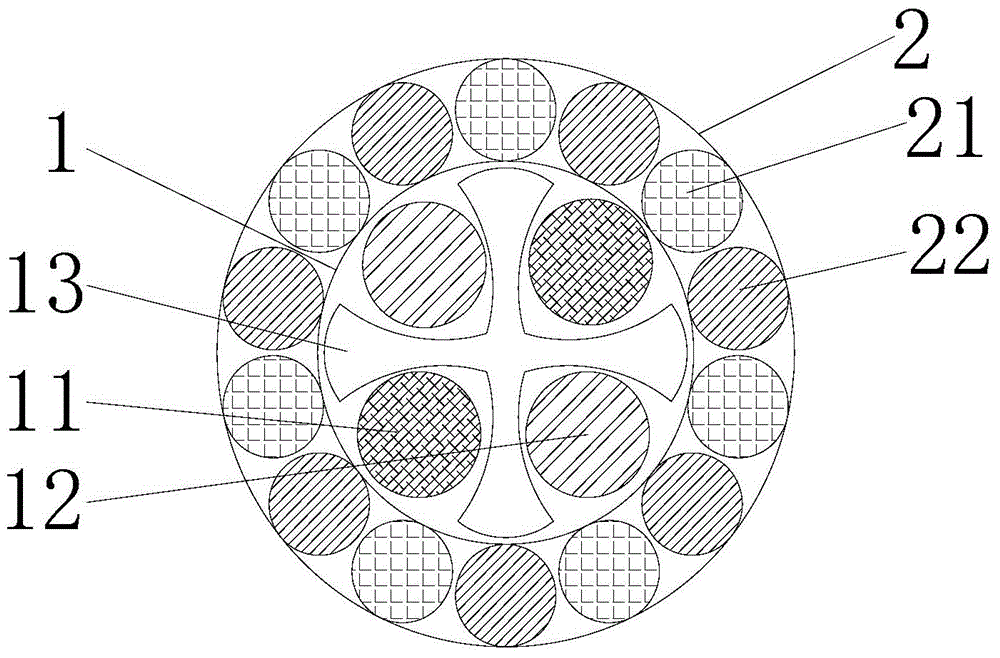

[0017] refer to figure 1 , a novel blended wool of the present invention, comprising a central layer 1 and a surface layer 2, the surface layer 2 is wrapped around the central layer 1, and the central layer 1 is made of mulberry silk 11, long-staple cotton 12 and chitin fiber 13. The surface layer 2 is formed by mixing modal fiber 21 and wool 22, the content of mulberry silk 11 in the central layer 1 is 5-15 parts, the content of long-staple cotton 12 is 25-40 parts, and the content of chitin fiber 13 is 30 parts. ~50 parts, the modal fiber 21 in the surface layer 2 is 30~50 parts, the wool 22 is 30~50 parts, the wool 22 adopts unmyelinated hair, the wool 22 adopts fine wool, and the quality count of the fine wool It is 60~80, and the diameter of wool 22 is 25~40um. .

[0018] The surface layer 2 is composed of modal fibers 21 and wool 22 distributed at equal intervals of 1:1. In the central layer 1, mulberry silk 11 is 10 parts, long-staple cotton 12 is 35 parts, and chitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com