Electrostatic chuck and plasma processing equipment

A technology of electrostatic chuck and chuck body, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of increased heat loss of heating element 16, uneven temperature of chuck body 110, and reduced heating efficiency of electrostatic chuck. Achieve the effects of reducing heat loss, improving heating efficiency and heating uniformity, and ensuring sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order for those skilled in the art to better understand the technical solution of the present invention, the electrostatic chuck and the plasma processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

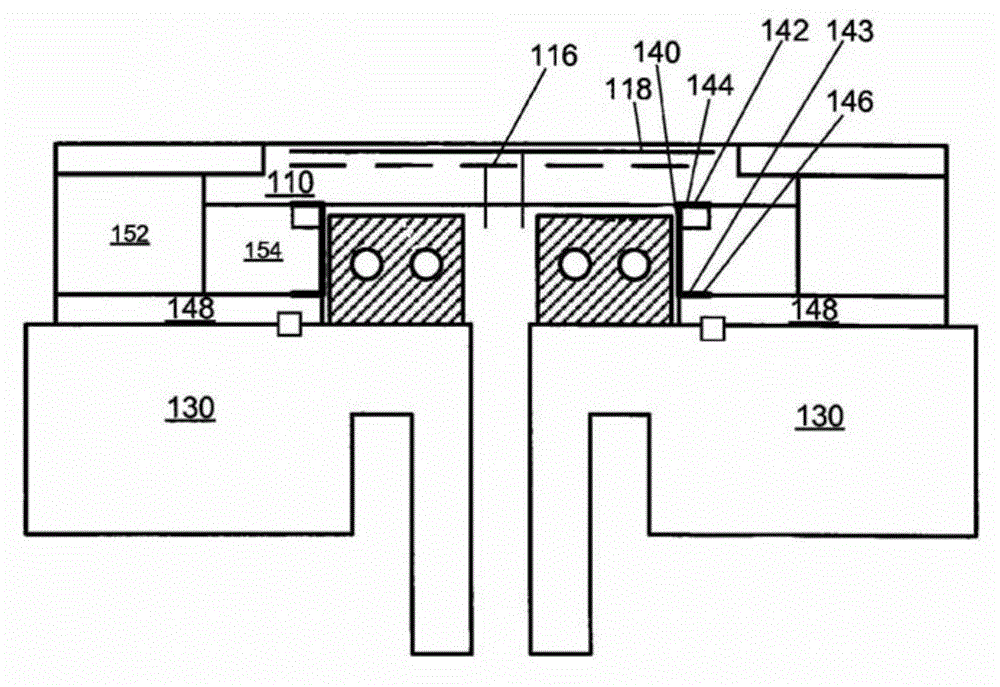

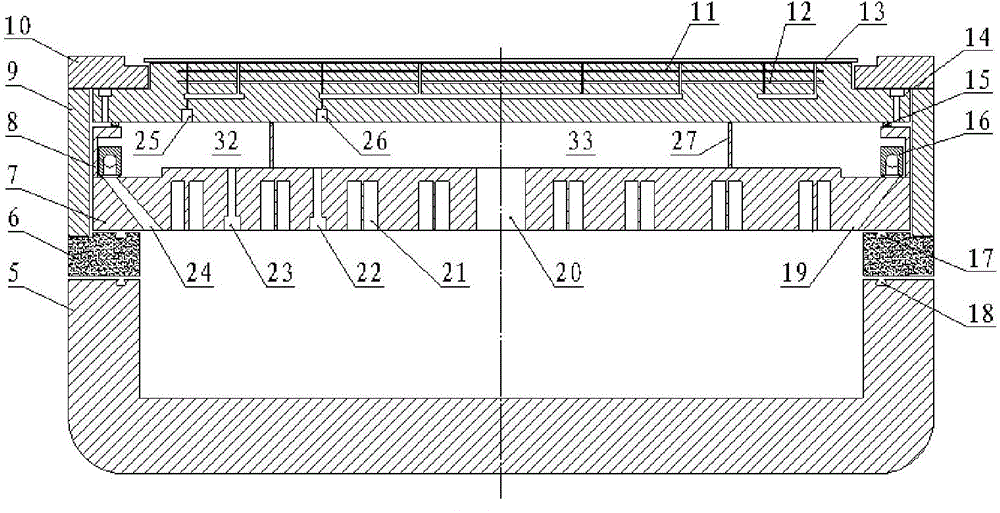

[0036] Figure 3A A cross-sectional view of an electrostatic chuck provided by an embodiment of the present invention. Figure 3B for Figure 3A Partial enlarged view of the middle electrostatic chuck. Please also refer to Figure 3A and Figure 3B , the electrostatic chuck includes a chuck for carrying a workpiece 13 to be processed, a base 5 , a cooling plate 7 and a thermal insulation assembly 8 . Wherein, the chuck includes a chuck body 14 , an electrostatic electrode 11 and a heating unit 12 arranged in the chuck body 14 . The electrostatic electrode 11 is connected to a DC power supply (not shown in the figure), and the DC power supply provides energy to the electrostatic electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com