Lithium battery pack charging method

A charging method and technology of lithium battery packs, which are applied in the direction of secondary battery charging/discharging, battery circuit devices, batteries, etc., can solve the problems of shortening the life of battery packs and large inconsistencies of battery cells, so as to prolong the charging time and reduce the size of the battery. Differentiation, the effect of long battery pack life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

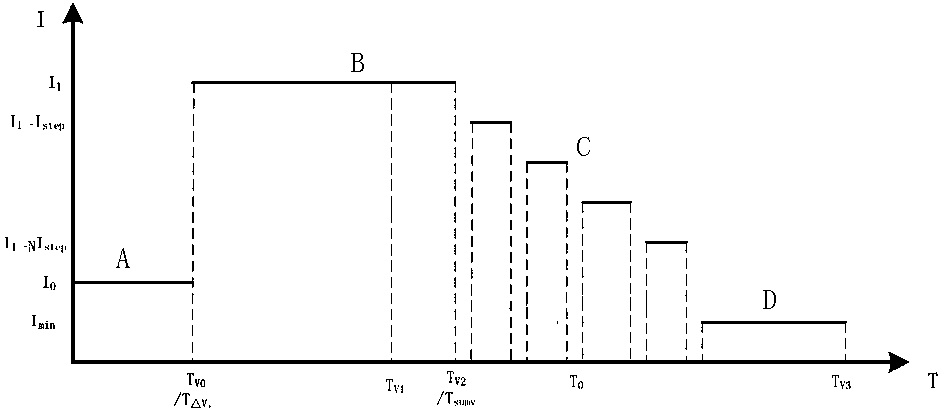

[0018] Such as figure 1 As shown, a lithium battery pack charging method, the entire charging process includes a constant current precharge mode, a constant current equalization charging mode, a constant voltage current charging mode, and a constant current trickle charging mode. These four charging modes are carried out in sequence, so that the differences of battery cells are gradually reduced. The following is an example of a 20V 100AH lithium iron phosphate battery pack:

[0019] Constant current pre-charge mode A: After charging is turned on, refer to the battery factory setting value, and use the battery's nominal capacity of 0.1C to perform a small current constant current value 0 =10A precharge, the small current constant current value can be recalibrated as the battery capacity decays, when the average voltage of the battery pack reaches the set value V O =2.8V or the difference between the highest cell voltage and the lowest cell voltage △V (Vmax-Vmin) reaches the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com