Preparation technology of ampelopsis grossedentata green tea

A production process and technology for rattan tea, applied in the field of production technology of rattan tea green tea, can solve the problems of time-consuming brewing of fermented tea, strong tea flavor, etc., and achieve the effects of improved production rate, easy technology and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

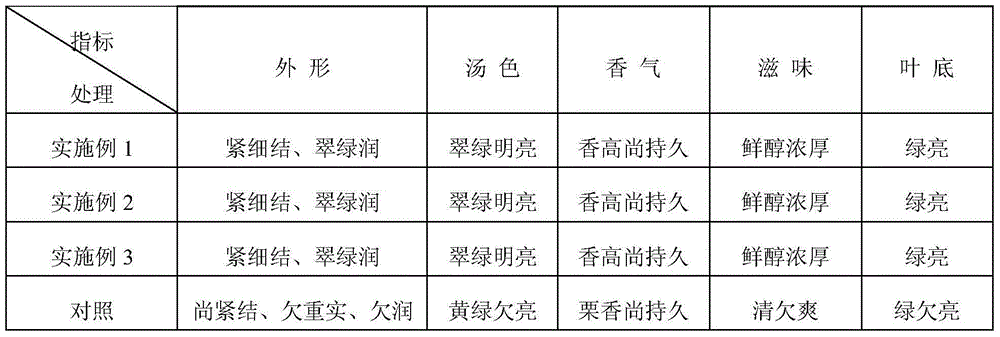

Examples

Embodiment 1

[0035] Fresh leaf raw materials: collect fresh leaves of rattan tea varieties, and pick one bud and one leaf when the delicate tea buds picked before Qingming is one bud and three leaves.

[0036] Cool green: 40min / 18℃.

[0037] Qingliangqing: Control the weight loss at 4%.

[0038] Shaking: Slow shaking motion is the main method to promote water movement, remove bitterness and astringency, and increase aroma.

[0039] Crimping: Quickly kill at a high temperature of 180°C for 2 minutes, and the moisture content of the cured leaves is 50%.

[0040] Kneading: Air pressure 6min→light pressure 4min.

[0041] Mao fire: Mao fire uses 84-type pearl tea pot, the pot temperature is about 120 ℃, and the fire is 3 minutes.

[0042] Shaping: The temperature of the pot is about 100℃, and the shaping is divided into 5 times, each time is 20 minutes, and the pot is left to cool for 3 minutes.

[0043] Full heat: temperature 100 ℃, bake for 2 minutes, bake to 5% water content.

[0044] Tilting incense: The...

Embodiment 2

[0047] Fresh leaf raw materials: collect fresh leaves of rattan tea varieties, and pick one bud and one leaf when the delicate tea buds picked before Qingming is one bud and three leaves.

[0048] Cool green: 40min / 22℃.

[0049] Qingliangqing: Control the weight loss at 5%.

[0050] Shaking: Slow shaking motion is the main method to promote water movement, remove bitterness and astringency, and increase aroma.

[0051] Cure: Quickly kill at 220 ℃ high temperature, cure for 3 minutes, and the water content of the cured leaves is 50%.

[0052] Kneading: Air pressure 6min→light pressure 4min.

[0053] Mao fire: Mao fire uses 84-type pearl tea pot, the pot temperature is about 120 ℃, and the fire is 5 minutes.

[0054] Plastic surgery: The temperature of the pot is about 100℃, and the plastic surgery is divided into 5 times, each time is 25 minutes, and the pot is left to cool for 5 minutes.

[0055] Full heat: temperature 100 ℃, bake 4min, bake to 6% water content.

[0056] Tilting incense: Th...

Embodiment 3

[0059] Fresh leaf raw materials: Tengcha tea, the delicate tea buds picked before Qingming, namely one bud and three leaves, pick one bud and one leaf.

[0060] Cool green: 40min / 18℃.

[0061] Qingliangqing: Control the weight loss at 4%.

[0062] Shaking: Slow shaking motion is the main method to promote water movement, remove bitterness and astringency, and increase aroma.

[0063] Crimping: Quickly kill at a high temperature of 180°C for 2 minutes, and the moisture content of the cured leaves is 50%.

[0064] Kneading: Air pressure 6min→light pressure 4min.

[0065] Mao fire: Mao fire uses 84-type pearl tea pot, the pot temperature is about 120 ℃, and the fire is 3 minutes.

[0066] Shaping: The temperature of the pot is about 100℃, and the shaping is divided into 5 times, each time is 20 minutes, and the pot is left to cool for 3 minutes.

[0067] Full heat: temperature 100 ℃, bake for 2 minutes, bake to 5% water content.

[0068] Tilting incense: The temperature is about 130℃, and it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com