Phycomycete complex fermented feed additive and preparation method thereof

A feed additive, compound fermentation technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problem of little production and development, and achieve the effect of promoting animal growth, improving survival rate, and enriching nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

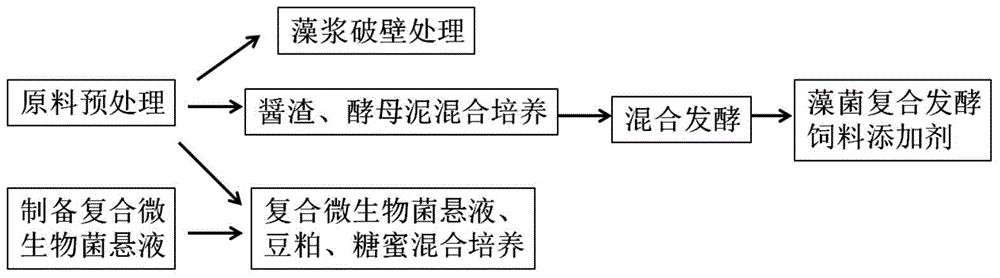

Method used

Image

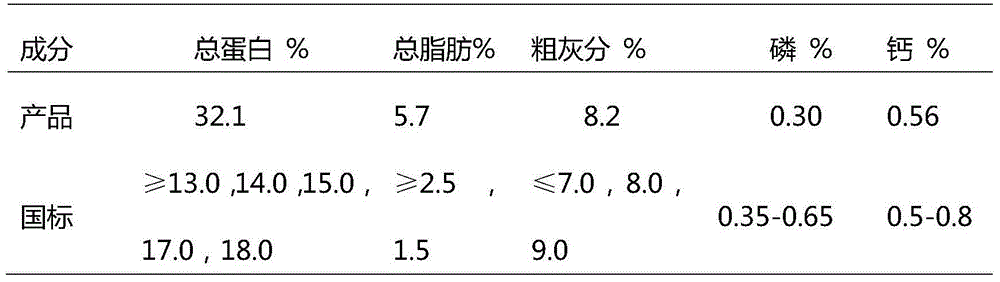

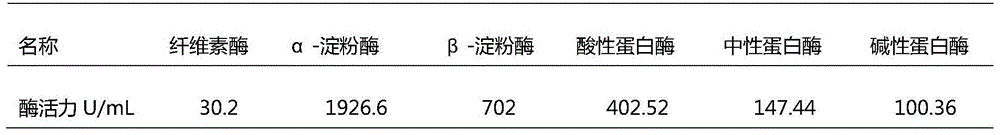

Examples

preparation example Construction

[0023] A preparation method for preparing an algae and bacteria compound fermented feed additive includes the following steps:

[0024] 1) Prepare algae powder (spirulina powder or chlorella algae powder) and water in a ratio of 1:10 to obtain algae slurry;

[0025] 2) Weigh 10-40 parts by weight of the algae pulp obtained in step 1) and 0.01-0.12 parts by weight of cellulase, mix them evenly, and perform wall breaking treatment at a temperature of 40-45°C, a pH of 5.5, and stirring for 24 hours to obtain Raw material algae pulp for wall breaking treatment;

[0026] 3) Weigh 5-8 parts by weight of sauce residue, add 20-32 parts by weight of water, and mix evenly to obtain a thin sauce residue liquid;

[0027] 4) Mix the thin sauce residue liquid obtained in step 3) with 25-35 parts by weight of yeast puree, mix uniformly, and ferment culture at 28-34° C., 60-100 rpm, and continuously culture for 24 hours to obtain mixture I;

[0028] 5) Weigh 15-30 parts by weight of soybean meal, add ...

Embodiment 1

[0035] An algae and bacteria composite fermentation feed additive, which contains: 10kg of algae pulp, 5kg of molasses, 5kg of sauce residue, 25kg of yeast mud, 25kg of soybean meal, 10kg of composite microorganism suspension, 0.01kg of cellulase, and 145kg of water.

[0036] A preparation method for preparing an algae and bacteria compound fermented feed additive includes the following steps:

[0037] 1) Prepare spirulina powder and water in a ratio of 1:10 to obtain algae slurry;

[0038] 2) Weigh 10kg of the algae pulp obtained in step 1) and 0.01kg of cellulase, mix them uniformly, and perform wall breaking treatment at a temperature of 40°C, pH value of 5.5, and stirring for 24 hours to obtain the raw material algae pulp for wall breaking treatment;

[0039] 3) Weigh 5 kg of sauce residue, add 20 kg of water, and mix well to obtain a thin sauce residue liquid;

[0040] 4) Mix the thin sauce residue liquid obtained in step 3) with 25 kg of yeast puree, and then ferment and culture a...

Embodiment 2

[0046] An algae and bacteria composite fermentation feed additive, containing: 15kg of algae pulp, 8kg of molasses, 8kg of sauce residue, 35kg of yeast mud, 30kg of soybean meal, 15kg of composite microorganism suspension, 0.045kg of cellulase, and 182kg of water.

[0047] A preparation method for preparing an algae and bacteria compound fermented feed additive includes the following steps:

[0048] 1) Prepare chlorella algae powder and water in a ratio of 1:10 to obtain algae slurry;

[0049] 2) Weigh 15 kg of the algae pulp obtained in step 1) and 0.045 kg of cellulase, mix them evenly, and perform wall breaking treatment at a temperature of 45°C, pH value of 5.5, and stirring for 24 hours to obtain the raw material algal pulp for wall breaking treatment;

[0050] 3) Weigh 8 kg of sauce residue, add 32 kg of water, and mix well to obtain a thin sauce residue liquid;

[0051] 4) Mix the thin sauce residue liquid obtained in step 3) with 35 kg of yeast puree, mix uniformly, and ferment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com