Potato cake stuffing and processing method thereof

A potato and mashed potato technology, which is applied in baking, baked food, food preparation, etc., can solve the problem that pastry fillings cannot meet the purpose of coarse grain health preservation, and achieve good economic benefits, good taste, and good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

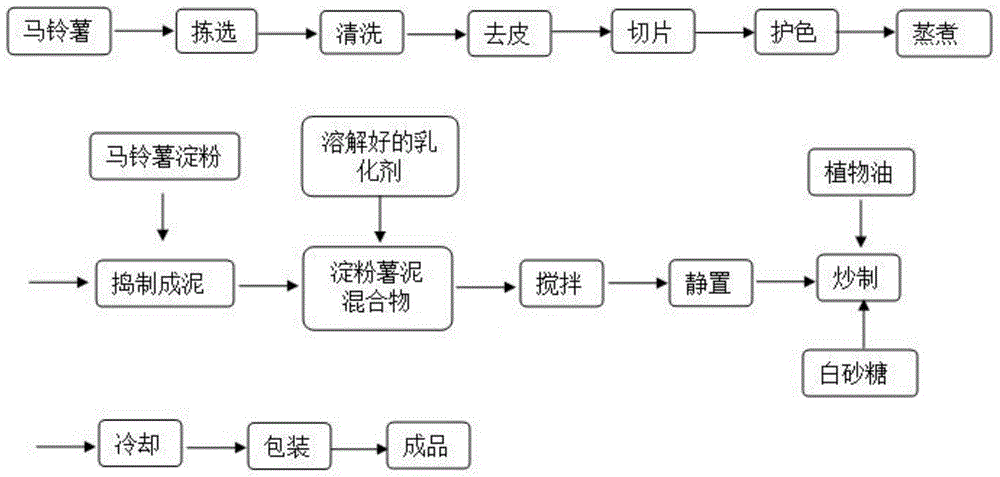

Image

Examples

Embodiment 1

[0050] Formula: The main ingredients are composed of the following components in terms of mass percentage: 38% mashed potato, 38% potato starch, 14% vegetable oil, and 10% white sugar. The sum of the mass percentages of the above components is 100%; the amount of auxiliary materials added: The mass of the main ingredient is 0.4% monoglyceride, and the mass of the main ingredient is 0.04% of the sucrose fatty acid ester.

[0051] Step 1, preparation of mashed potatoes

[0052] Wash the potatoes, remove bud eyes and discolored parts, and peel them. Cut the processed potatoes into thin slices with a thickness of 1 cm, soak them in water to prevent discoloration, and cook them at 100°C for 40 minutes. Cool the steamed potatoes to room temperature (25°C) within 30 minutes and mash them into puree;

[0053] Step 2, the deployment of fillings

[0054] Stir and mix the potato starch and mashed potatoes evenly; mix the monoglyceride and sucrose fatty acid ester, add 5% vegetable oil ...

Embodiment 2

[0060]Formula: The main ingredients are composed of the following components in terms of mass percentage: 40% mashed potato, 40% potato starch, 12% vegetable oil, and 8% white sugar. The sum of the mass percentages of the above components is 100%; the amount of auxiliary materials added: The mass of the main ingredient is 0.6% of monoglyceride, and the mass of the main ingredient is 0.06% of sucrose fatty acid ester.

[0061] Step 1, preparation of mashed potatoes

[0062] Wash the potatoes, remove bud eyes and discolored parts, and peel them. Cut the processed potatoes into thin slices with a thickness of 1.5 cm, soak them in water to prevent discoloration, and cook them at 100°C for 45 minutes. Cool the steamed potatoes to room temperature (25°C) within 30 minutes and mash them into puree;

[0063] Step 2, the deployment of fillings

[0064] Stir and mix the potato starch and mashed potatoes evenly; mix the monoglyceride and sucrose fatty acid ester, add 4% vegetable oil a...

Embodiment 3

[0070] Formula: The main ingredients are composed of the following components in terms of mass percentages: 42% mashed potato, 42% potato starch, 10% vegetable oil, and 6% white sugar. The sum of the mass percentages of the above components is 100%; the amount of auxiliary materials added: The mass of the main ingredient is 0.8% monoglyceride, and the mass of the main ingredient is 0.08% of the sucrose fatty acid ester.

[0071] Step 1, preparation of mashed potatoes

[0072] Wash the potatoes, remove bud eyes and discolored parts, and peel them. Cut the processed potatoes into thin slices with a thickness of 2 cm and soak them in water to prevent discoloration. Steam them at 100°C for 50 minutes. Cool the steamed potatoes to room temperature within 30 minutes ( 25°C) and pounded into mud;

[0073] Step 2, the deployment of fillings

[0074] Stir and mix the potato starch and mashed potatoes evenly; mix the monoglyceride and sucrose fatty acid ester, add 3% vegetable oil and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com