Welding method for tube plate of robot

A tube sheet welding and robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large volume and weight of pressure vessels, complicated device use and installation process, and low degree of automation, etc. The effect of ensuring welding quality, high degree of intelligence, and improving welding processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

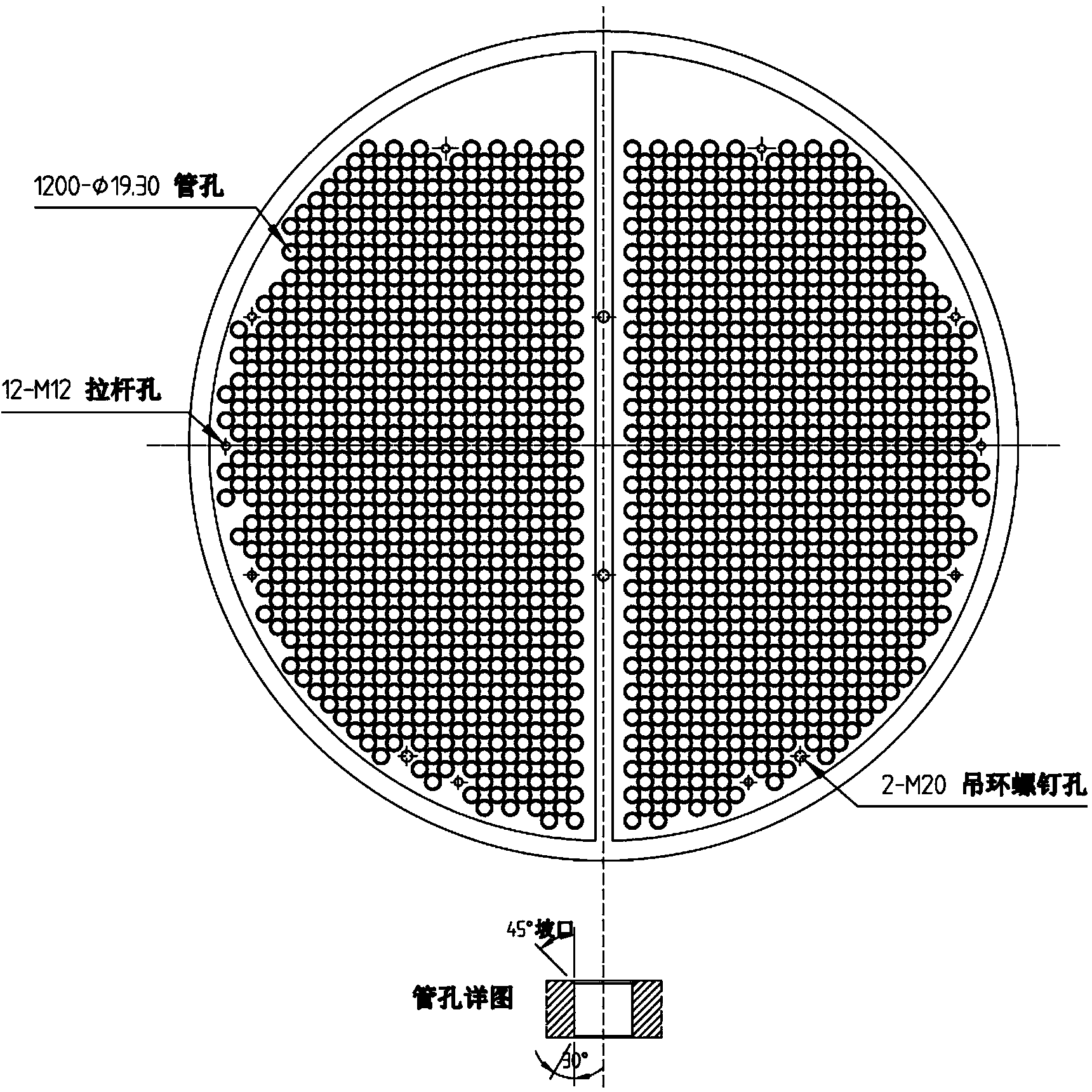

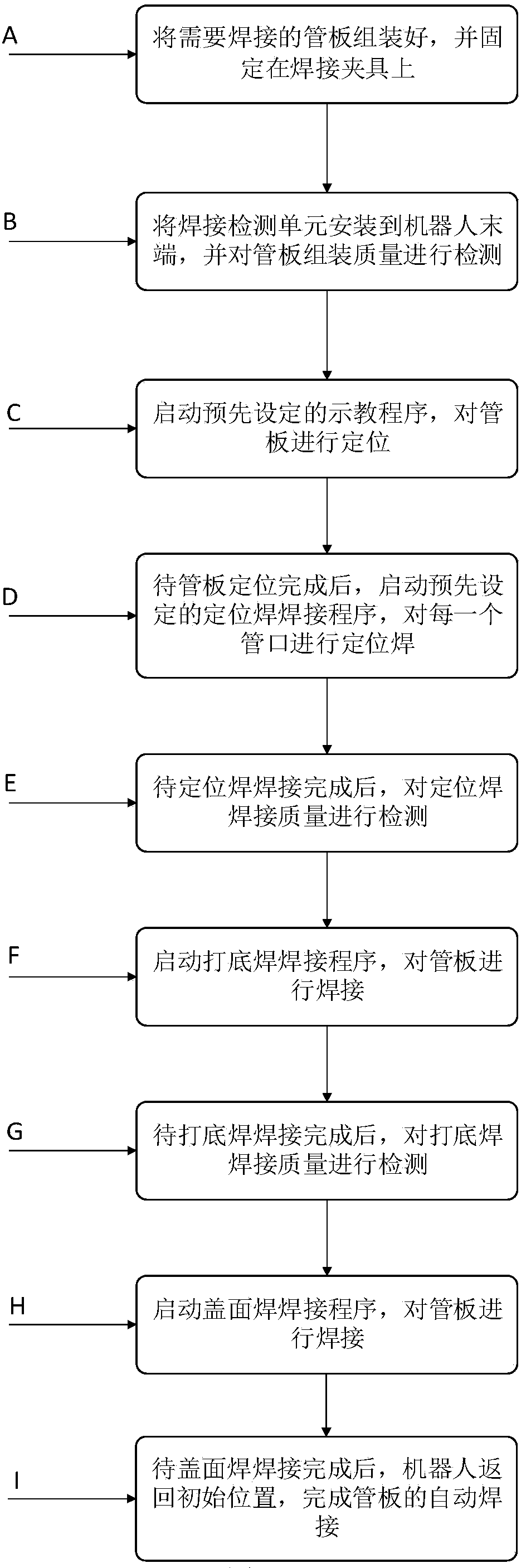

[0023] refer to figure 1 and figure 2 , a robot tube sheet welding method, comprising the following steps:

[0024] A. Assemble the tube sheet to be welded and fix it on the welding fixture;

[0025] At this time, the welding operator assembles the tube sheet, and after confirming that it meets the standard, clamps and fixes it.

[0026] B. Install the welding inspection unit to the end of the robot to inspect the assembly quality of the tube sheet;

[0027] In step B, after the welding inspection unit is installed on the end of the robot, it is necessary to inspect the assembly quality of the tube sheet. The method for inspecting the assembly quality of the tube sheet is a robot vision method, and the external dimensions of the tube sheet are determined by CCD image acquisition and image processing. , the thickness and material of the assembled steel plate, the cleaning status of the area to be welded, the size of the weld processing groove and the welding material to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com