Landfill leachate zero concentrated solution deep treatment system and method

A technology for landfill leachate and advanced treatment, applied in multi-stage water treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problem of inability to effectively reduce pollutant load, high operating and investment costs, operating energy consumption and costs Improve and other problems, to avoid high cost and high energy consumption problems, solve the problem of concentrated liquid disposal, avoid the effect of environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

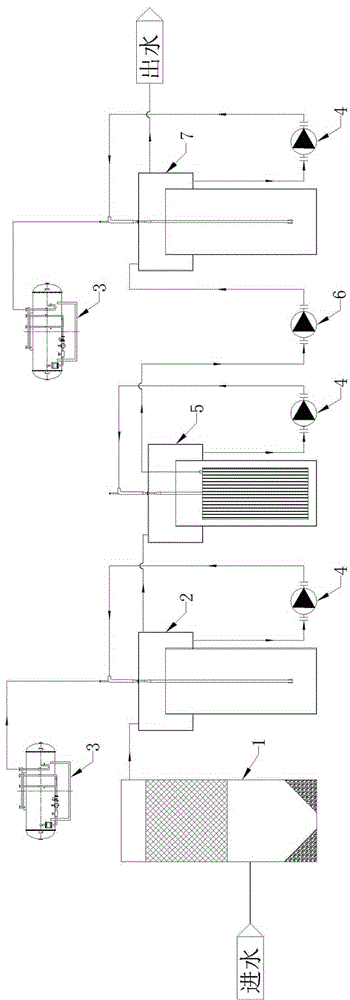

[0030] See figure 1 , which shows a landfill leachate zero concentrate advanced treatment system of this embodiment, wherein:

[0031] The equipment labeled 1 is a flocculation catalytic filtration reactor CFR; a precious metal frame is fixed inside it, and the precious metal frame is filled with active fillers. Refractory organic matter interacts with the active filler in the reactor, and under the catalysis of the precious metal in the reactor, the refractory organic pollutants in the landfill leachate interact with the active filler, and some of the organic pollutants Under this action, the substances are degraded into easily biodegradable substances, and the other part of the refractory macromolecular organic substances are precipitated in the form of precipitates and replaced with heavy metal ions at the same time, which reduces the COD of landfill leachate and removes the toxicity of landfill leachate. ; Wherein, a specific example of the flocculation catalytic filtrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com