Production process of energy-saving sintered shale hollow blocks with full internal combustion once-by-combustion

A hollow block and production process technology, which is applied in the field of energy-saving sintered shale hollow block full internal combustion once-combustion production process, can solve the problems of high cost, waste of resources, and less process flow, and achieve a high degree of automation and energy saving resource and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

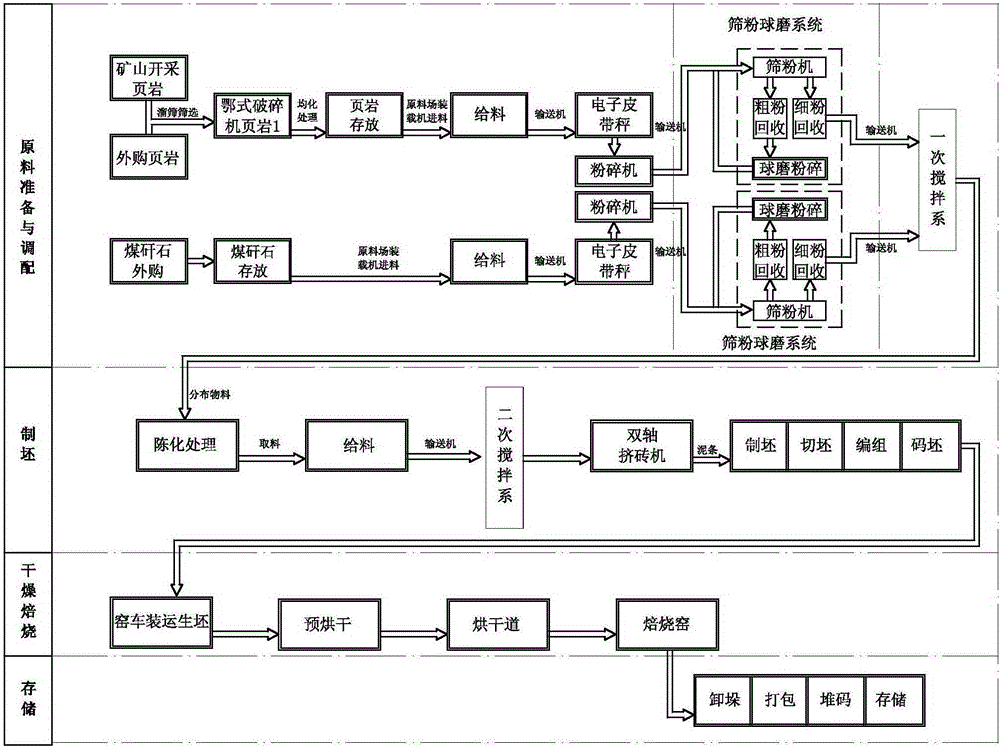

[0049] Such as figure 1 Shown: an energy-saving sintered shale hollow block full internal combustion one-time co-sintering production process, which consists of four steps of raw material preparation and deployment, billet making, drying and co-sintering and storage, and is characterized in that:

[0050] 1. Raw material preparation and deployment

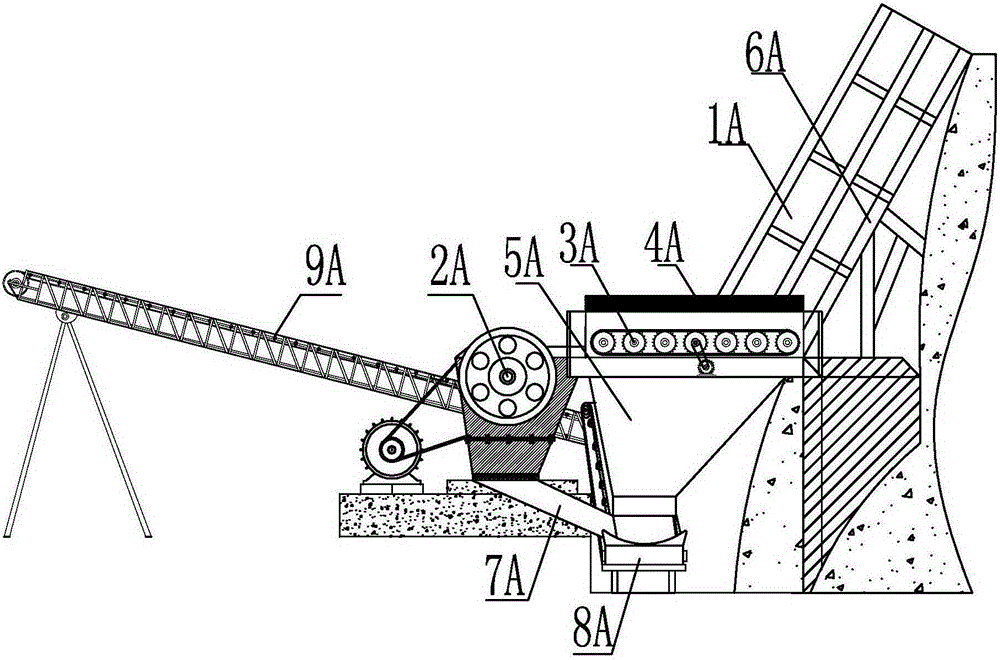

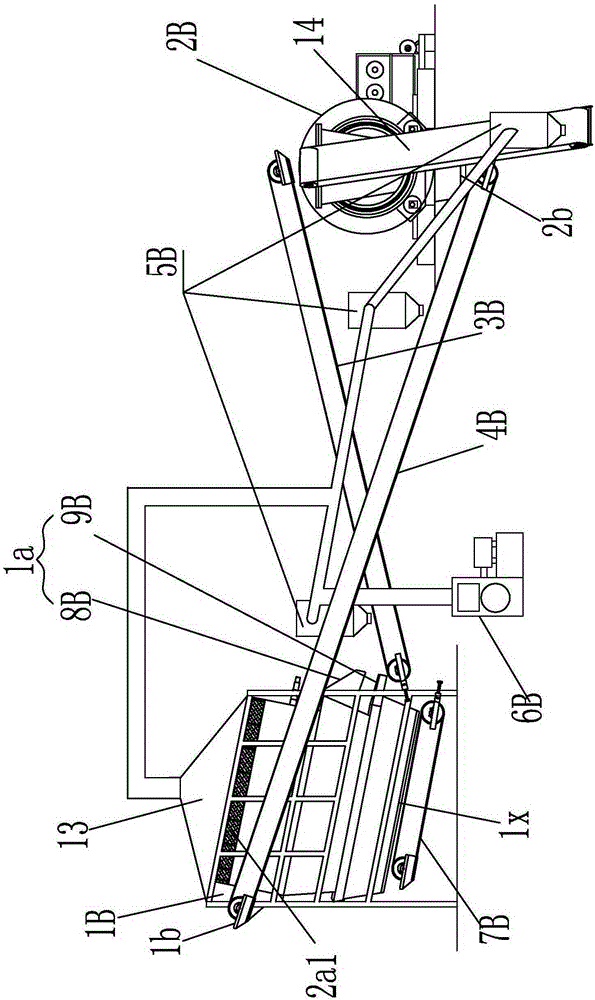

[0051] a. Send the mined or purchased shale to the crushing device for homogenization and crushing and separate the coarse and fine powder. The coarse powder is homogenized and crushed again, and the fine powder is discharged with a particle size of less than 3mm. The fine powder is accurately dosed by an electronic belt scale , and the prepared shale is sent to the pulverizer for crushing, and then to the sieving and ball milling system for circular fine grinding and sieving out materials with a particle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com