A kind of connection method of ceramic green body

A ceramic green body and connection method technology, which is applied in the field of ceramic-ceramic connection, can solve the problems affecting the uniformity of the microstructure of the connected body and high slurry dependence, so as to improve the uniformity of the microstructure, improve the mechanical properties, and promote interconnection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] (1) Preparation of ceramic gel: use water as solvent, add water-soluble butene polymer and ceramic powder, wherein: the mass ratio of water-soluble butene polymer to water can be 0.005:1~0.05 : 1; the solid phase content of the ceramic powder can be between 50~58vol%. Inject the prepared ceramic slurry into the forming mold, and then perform in-situ curing and aging at 30°C to 80°C after sealing;

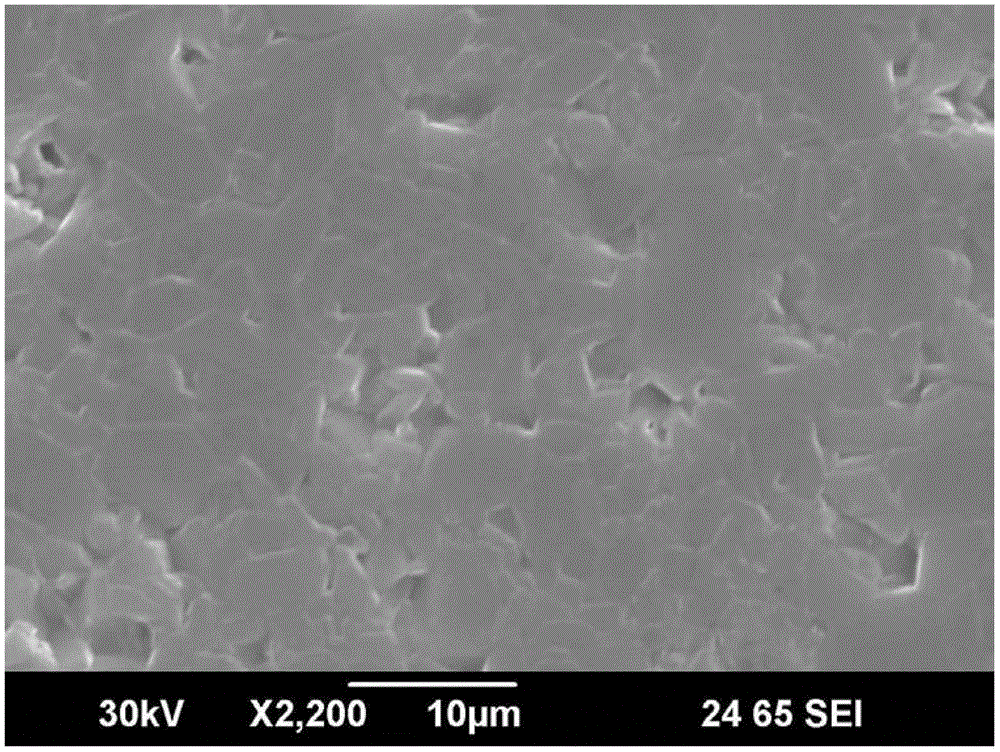

[0026] (2) After the aged ceramic gel is removed from the mold, the flatness of the connection surface is treated, and then the two ceramic gels are directly butted together to realize the connection. The functional groups of the organic molecular chains in the ceramic gel have a bonding effect and are reactive during the aging process, so that the ceramic gel exhibits natural plasticity and viscosity. The two connecting surfaces are connected into a whole by the action of organic molecules, and there is no need to add any adhesive or apply pressure to the connection.

[00...

Embodiment 1

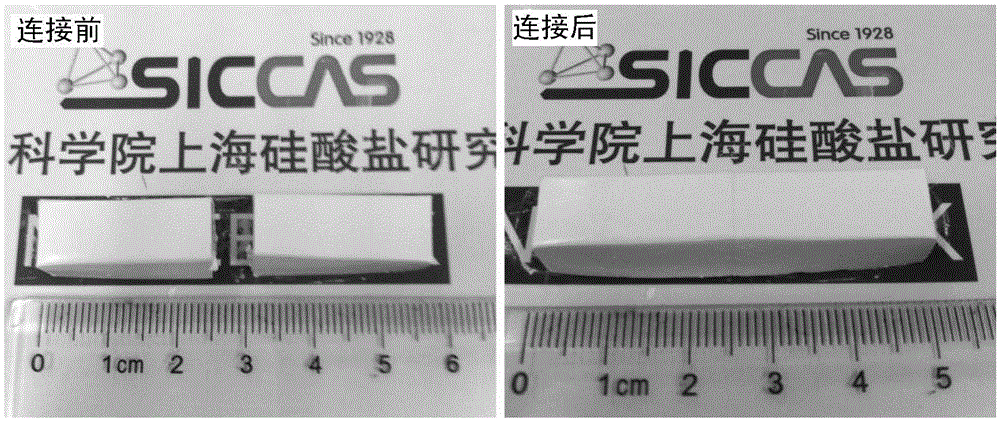

[0039] Embodiment 1: the connection method of alumina ceramic gel

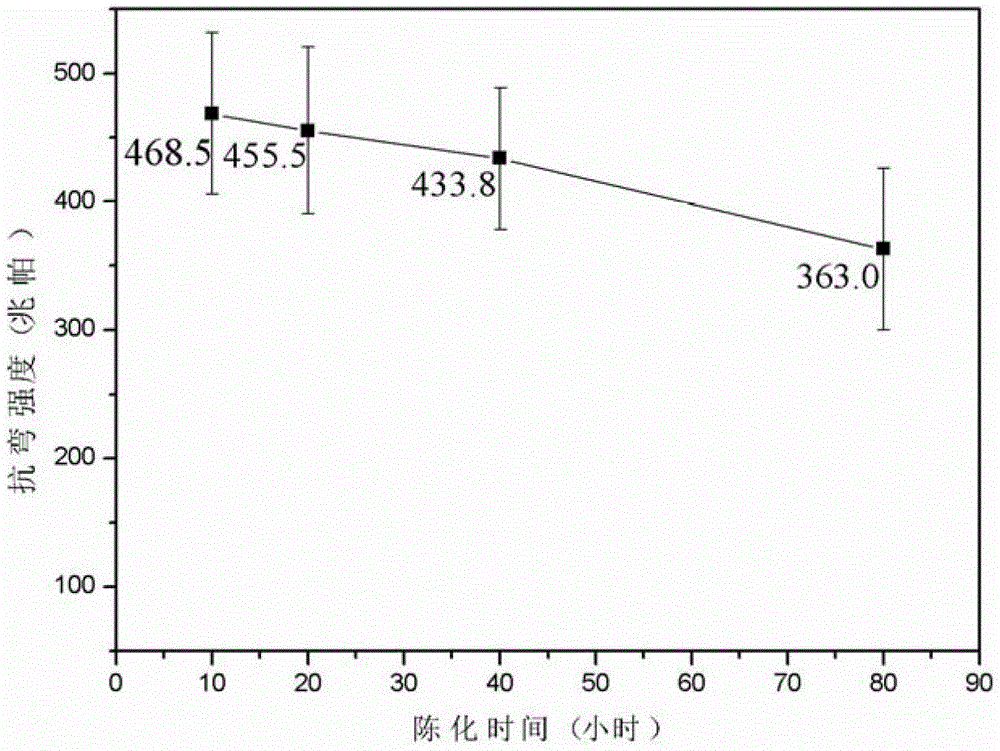

[0040] The alumina ceramic powder used is provided by Sumitomo Chemical Co., Ltd., Japan, with an average particle size of about 0.45 μm. Add 0.6g of cis-butene polymer combined with long and short chains to 50g of deionized water, mix and dissolve in water for 10min, then add 200g of alumina ceramic powder, mix and ball mill with a planetary ball mill for 30min, after mixing evenly, vacuum remove the ceramic slurry gas. After degassing, the slurry was injected into a plastic mold, sealed with a PVC film and placed in a 50°C constant temperature box for in-situ curing and aging. After aging for 1 to 80 hours, take it out and demould, and perform mechanical cutting on the connecting surface to ensure the cleanliness and flatness of the surface, and then figure 1 The alumina ceramic gels are shown directly butted against each other. The connected ceramic gel is dried in a constant temperature and humidity box...

Embodiment 2

[0041] Embodiment 2: the preparation method of zirconia connector

[0042] Add 1.08 g of butene-based polymers combining long and short chains and 360 g of zirconia ceramic powder to 50 g of deionized water, and mix for 30 minutes with a planetary ball mill. After mixing evenly, the ceramic slurry is vacuum degassed, then poured into a plastic mold, sealed with a PVC film, and placed in a 50°C constant temperature box for in-situ curing and aging. After aging for 1 to 80 hours, take it out and demould, and perform mechanical cutting on the connecting surface to ensure the cleanliness and flatness of the surface. The zirconia ceramic gels are directly connected to each other, and the connected ceramic gels are dried in a constant temperature and humidity box. The drying is controlled at a temperature of 30°C and a humidity of 75%. After drying, the zirconia connected body can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com