Magnetically oriented ice-template method for conductive and wear-resistant composites

A technology of composite materials and ice templates, applied in the field of conductive and wear-resistant composite materials, can solve the problems that are not enough to meet the actual use requirements, and achieve the effect of low price and simple process principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

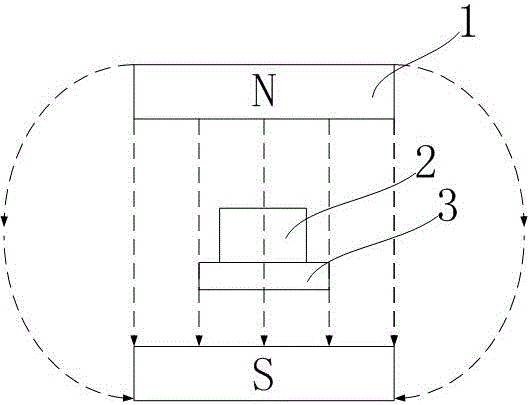

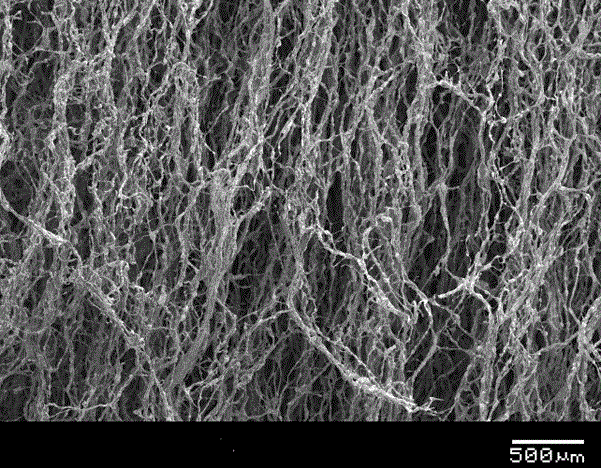

Method used

Image

Examples

Embodiment 1

[0039] (1) Place 1 g of multi-walled carbon nanotubes with a diameter of 10-30 nm and a length greater than 2 μm in concentrated H 2 SO 4 : concentrated HNO 3(Volume ratio) = 3:1 in 200ml mixed acid solution, ultrasonically oscillate for 20 minutes, freeze and stand for 10 minutes, and repeat this process for 3 hours; then ultrasonically oscillate for 20 minutes, stand at room temperature for 10 minutes, and after repeated treatment for 17 hours, wash with water until neutral. During the sonication process, keep the temperature at 40°C.

[0040] (2) the carbon nanotube that obtains in the step (1) is dropped into the 10g / L SnCl of 200ml 2 2H 2 Sensitization treatment was carried out in O and 40g / L HCl mixed solution for 40min, and then washed to neutrality; the carbon nanotubes after sensitization treatment were put into 0.5g / LPdCl 2 , 0.25mL HCl, 20g / LH 3 BO 3 200ml of the mixed solution was activated for 40min, followed by washing with water until neutral. Configure 1...

Embodiment 2

[0045] (1) 1.5 g of multi-walled carbon nanotubes with a diameter of 10-30 nm and a length greater than 2 μm were placed in concentrated H 2 SO 4 : concentrated HNO 3 (Volume ratio) = 3:1 in 250ml mixed acid solution, ultrasonically oscillate for 15 minutes, refrigerate for 15 minutes, and repeat this process for 3 hours; then ultrasonically oscillate for 20 minutes, and stand at room temperature for 10 minutes. After repeated treatment for 20 hours, wash with water until neutral. During sonication, keep the temperature at 45°C.

[0046] (2) the carbon nanotube that obtains in the step (1) drops into the 10g / L SnCl of 250ml 2 2H 2 Sensitization treatment was carried out in O and 40g / L HCl mixed solution for 40min, and then washed to neutrality; the carbon nanotubes after sensitization treatment were put into 0.5g / LPdCl 2 , 0.25mL HCl, 20g / LH 3 BO 3 250ml of the mixed solution was activated for 40min, followed by water washing to neutrality. Configure 1.5L plating soluti...

Embodiment 3

[0051] (1) 2 g of multi-walled carbon nanotubes with a diameter of 10-30 nm and a length greater than 2 μm were placed in concentrated H 2 SO 4 : concentrated HNO 3 (Volume ratio) = 3:1 in 250ml mixed acid solution, ultrasonically oscillate for 18 minutes, refrigerate for 13 minutes, and repeat this process for 3 hours; then ultrasonically oscillate for 20 minutes, and stand at room temperature for 10 minutes. After repeated treatment for 18 hours, wash with water until neutral. During the sonication process, keep the temperature at 50°C.

[0052] (2) the carbon nanotube that obtains in the step (1) drops into the 10g / L SnCl of 250ml 2 2H 2 Sensitization treatment was carried out in O and 40g / L HCl mixed solution for 40min, and then washed to neutrality; the carbon nanotubes after sensitization treatment were put into 0.5g / LPdCl 2 , 0.25mL HCl, 20g / L H 3 BO 3 250ml of the mixed solution was activated for 40min, followed by water washing to neutrality. Configure 2L plati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com