Device and method for smelting lithium through vacuum thermal reduction of metal

A metal heat and metal lithium technology, applied in the field of metallurgy, can solve the problems of low metal lithium grade, difficult operation, and immature metal lithium collection technology, and achieve high product yield and purity, convenient placement and removal, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

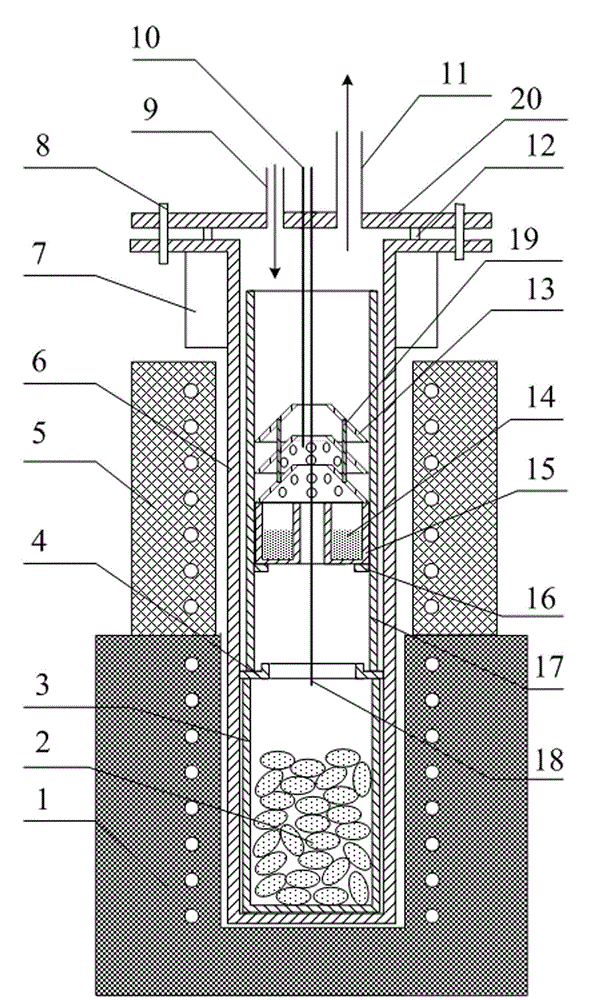

[0033] The structure of the vacuum metallothermic reduction lithium smelting device is as follows: figure 1 As shown, it includes a heating resistance furnace 1 and a reaction tank 6; the bottom of the reaction tank 6 is located in the heating resistance furnace 1, and the top of the reaction tank 6 is provided with a cooling water jacket 7; the top of the reaction tank 6 is sealed with the flange cover 20, The flange cover 20 is provided with a vacuum port 11 and an air filling hole 9;

[0034] The flange cover 20 is fixed together with the reaction tank 6 by fastening bolts 8, and a gasket 12 is arranged between the flange cover 20 and the reaction tank 6;

[0035] Wherein reaction tank 6 is placed with bucket 3, movable support 4 and support cylinder 17; Material bucket 3 is positioned at the bottom of reaction tank 6 and is positioned at the inside of heating resistance furnace 1, movable support 4 is placed on the top of bucket 3, and support cylinder 17 is placed on On ...

Embodiment 2

[0048] The device structure of the vacuum metallothermic reduction smelting lithium is the same as that of Example 1, the difference is that:

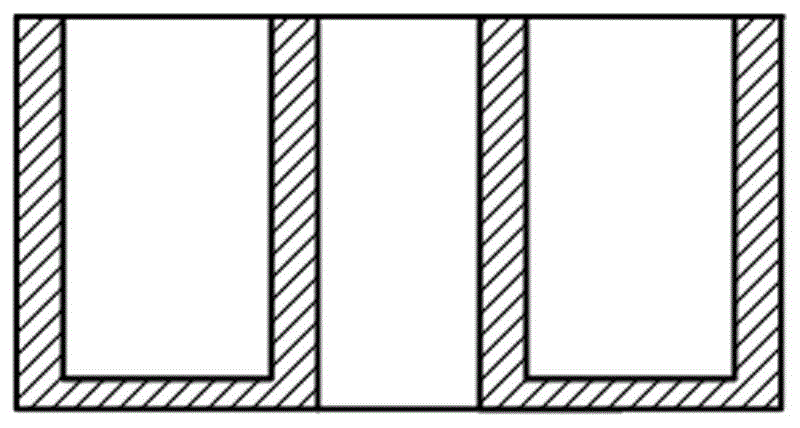

[0049] The condenser is composed of 2 condensing sheets, and the structure of the condensing sheet with through holes is as follows: Figure 7 shown;

[0050] The method of vacuum metallothermic reduction refining lithium is the same as embodiment 1, the difference is:

[0051] Lithium carbonate and calcium oxide are mixed at a molar ratio of 1:2.5, and calcined for 1.5 hours at 850°C and a vacuum degree of ≤100Pa to obtain lithium-containing clinker;

[0052] The mixing ratio of lithium-containing clinker and ferrosilicon alloy is 3.6:1 according to the molar ratio of lithium in lithium-containing clinker and silicon in ferrosilicon alloy; the weight content of silicon in ferrosilicon alloy is 85%;

[0053] Vacuum thermal reduction reaction, the reaction time is 4h;

[0054] Heat the reaction tank through the insulation resistance ...

Embodiment 3

[0057] The device structure of the vacuum metallothermic reduction smelting lithium is the same as that of Example 1, the difference is that:

[0058] Condenser consists of 1 condensing sheet, no condensing sheet with through holes;

[0059] The method of vacuum metallothermic reduction refining lithium is the same as embodiment 1, the difference is:

[0060] Lithium carbonate and calcium oxide are mixed at a molar ratio of 1:3, and calcined for 1 hour at 1000°C and vacuum degree ≤100Pa to obtain lithium-containing clinker;

[0061] The mixing ratio of lithium-containing clinker and ferrosilicon alloy is 4:1 according to the molar ratio of lithium in lithium-containing clinker and silicon in ferrosilicon alloy; the weight content of silicon in ferrosilicon alloy is 98%;

[0062] Vacuum thermal reduction reaction, the reaction time is 1.5h;

[0063] Heat the reaction tank through the insulation resistance furnace outside the reaction tank, control the temperature measured by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com