Method for judging gas fleeing time

A technology of gas escape and time, which is applied in the direction of mining fluid, earthwork drilling, measurement, etc., can solve the problems affecting the time of gas escape, gas production speed fluctuations, irregular changes, etc., to avoid inaccuracy, reduce interference, The effect of good technical applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for determining the gas escape time, wherein, the present embodiment adopts a natural outcrop sandstone core model, the core size is 30cm×4.5cm×4.5cm, the porosity is 22%, and the permeability is 1.7×10 -3 μm 2 ; The water used is oil well produced water, and the water type is CaCl 2 type, the salinity is 80.06g / L; the crude oil used is oilfield crude oil, the density of degassed crude oil is 0.8579g / mL, and the surface viscosity is 11.54mPa·s. Crude oil, the simulated crude oil viscosity is 4.87mPa s (45°C); CO 2 The purity of the gas is 99.99%, and the experimental temperature is 45°C.

[0039] The method for determining gas blow-by time provided in this embodiment includes the following steps:

[0040] Put the core in the core holder, check the tightness of the system, vacuumize the system, and then use pressurization to fully saturate the water produced by the oil wells in the oil field to obtain a water-saturated core with a rec...

Embodiment 2

[0049] This embodiment provides a method for determining the gas escape time, wherein, the present embodiment adopts a natural outcrop sandstone core model, the core size is 30cm×4.5cm×4.5cm, the porosity is 23%, and the permeability is 2.5×10 -3 μm 2 , the water used is oil well produced water, and the water type is CaCl 2 type, the salinity is 80.06g / L; the crude oil used is oilfield crude oil, the density of degassed crude oil is 0.8579g / mL, and the surface viscosity is 11.54mPa·s. Crude oil, the simulated crude oil viscosity is 4.87mPa s (45°C); CO 2 The purity of the gas is 99.99%; the experimental temperature is 45°C.

[0050] The method for determining gas blow-by time provided in this embodiment includes the following steps:

[0051] Put the core in the core holder, check the tightness of the system, vacuumize the system, and then use pressurization to fully saturate the water produced by the oil well in the oil field to obtain a water-saturated core with a recorded...

Embodiment 3

[0060] This example provides a method for determining the gas escape time, which is based on the low-permeability injection of CO in a domestic oilfield. 2 Take the pilot mine as an example. The mine includes multiple oil production wells. The implementation targets are 1# oil production well and 2# oil production well. Among them, the average liquid production of 1# oil production well is 9.1t / d, and the water content is 2.06 %.

[0061] The method for judging the gas channeling time of the 1# production well provided in this embodiment includes the following steps:

[0062] CO2 was carried out on the 1# production well 2 Gas displacement at constant pressure to obtain oil-gas mixture;

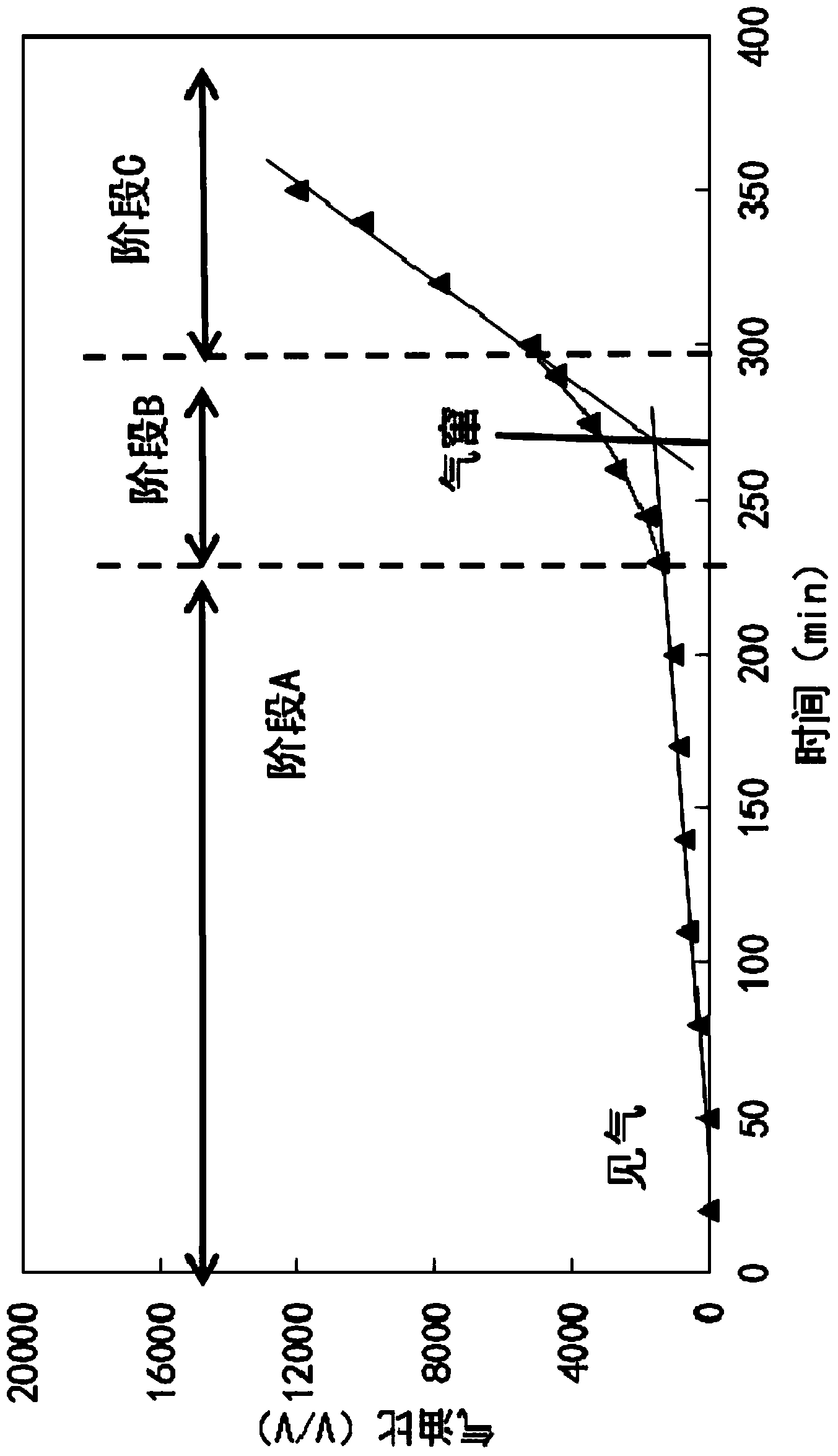

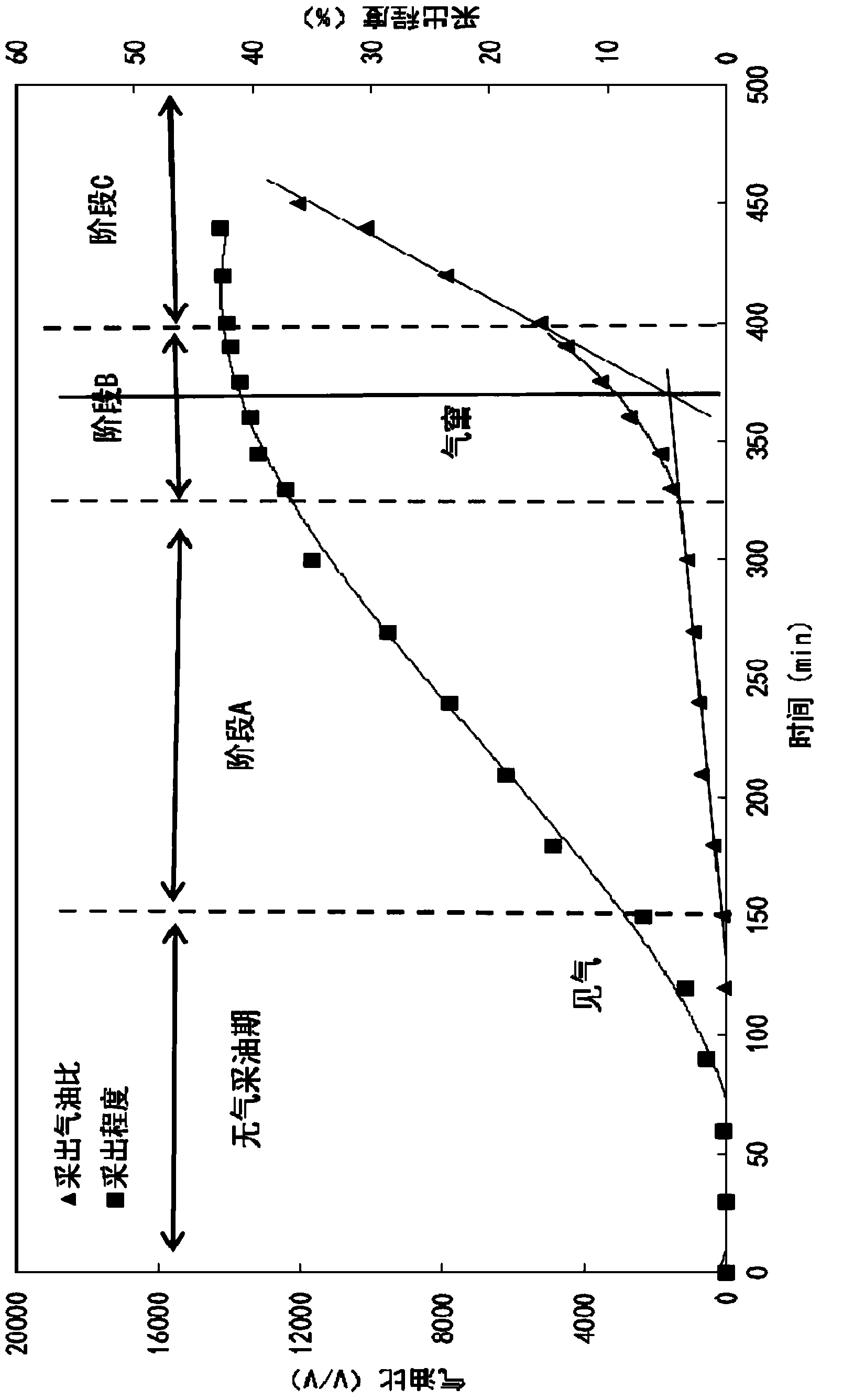

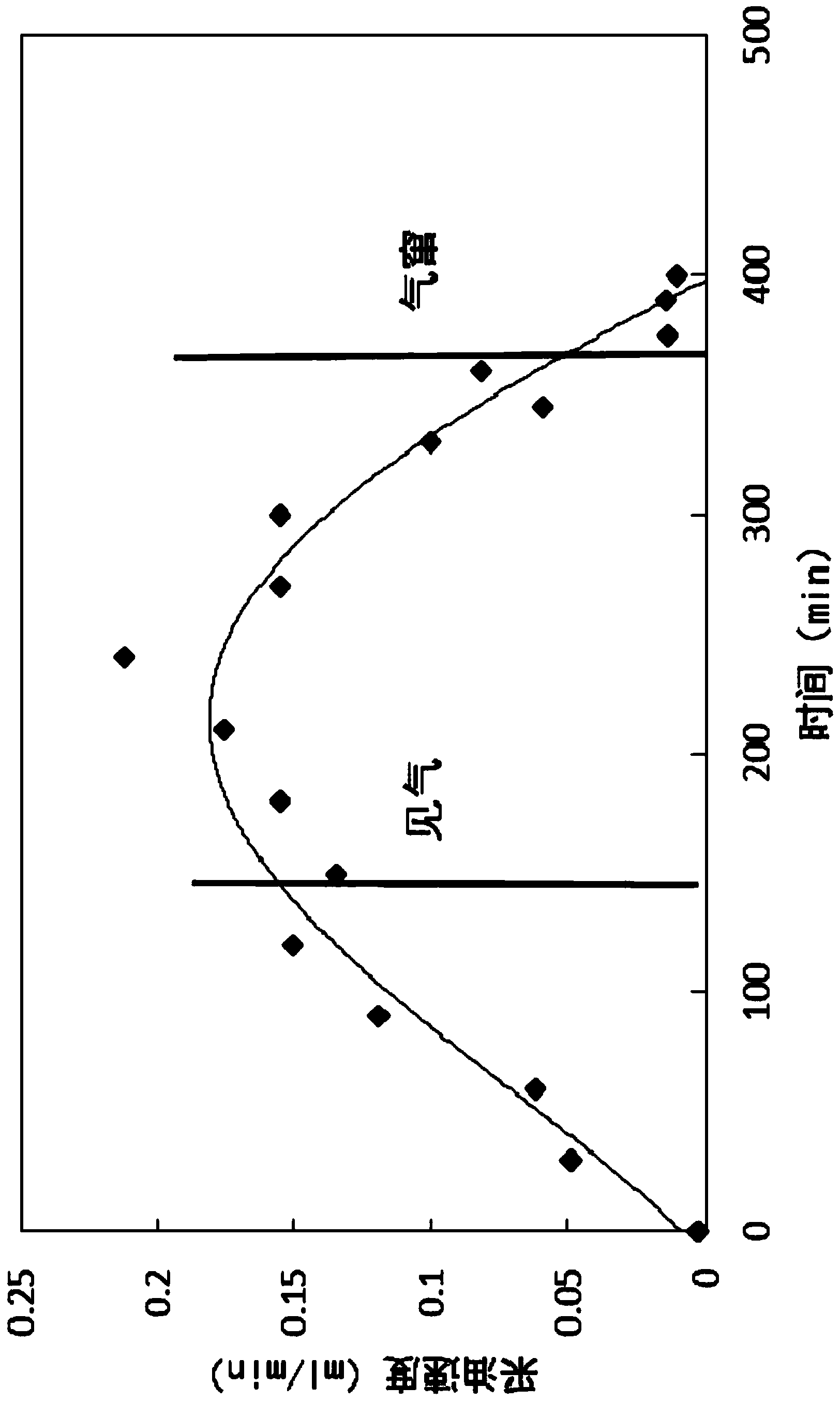

[0063] As the displacement progresses, the oil-gas mixture is separated, the oil output and gas output at each time point are measured, and the gas-oil ratio at each time point is obtained; the gas-oil ratio varies with the injection time. Figure 5 As shown, according to the change trend ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Salinity | aaaaa | aaaaa |

| Core permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com