A gas-filled temperature measuring system for a solid engine

A solid engine and engine technology, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of transparent glass surface hindering light wave collection, thermocouples are easy to fuse, glass damage, etc., to improve light wave collection efficiency, prevent damage, and experiment The effect of accurate and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

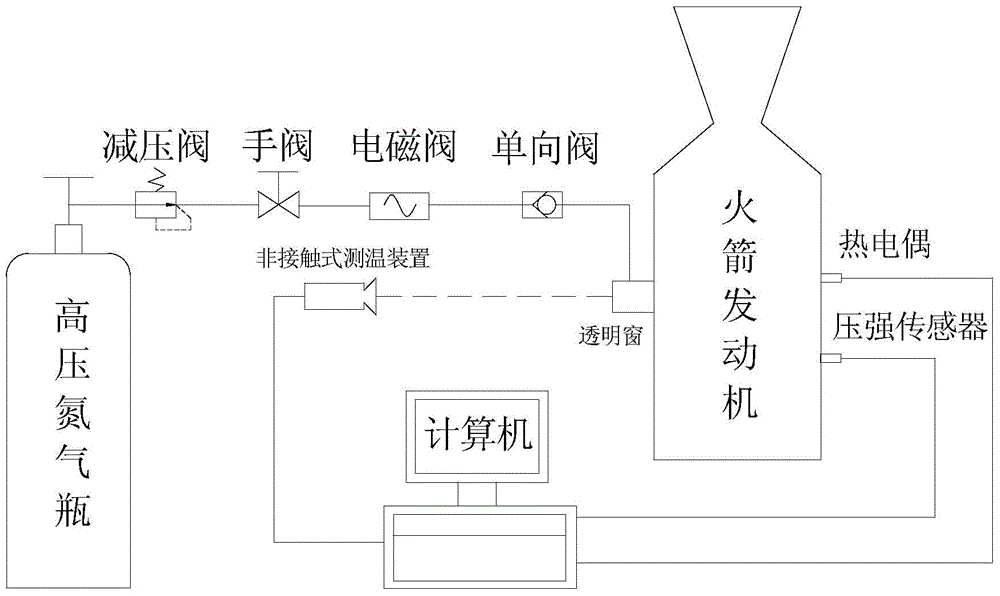

[0027] This embodiment is an air-filled temperature measurement system for a solid engine; it includes an engine, an air supply system, and a test system. The air supply system and the test system are installed outside the engine, and the engine is fixed on the test bench by bolts.

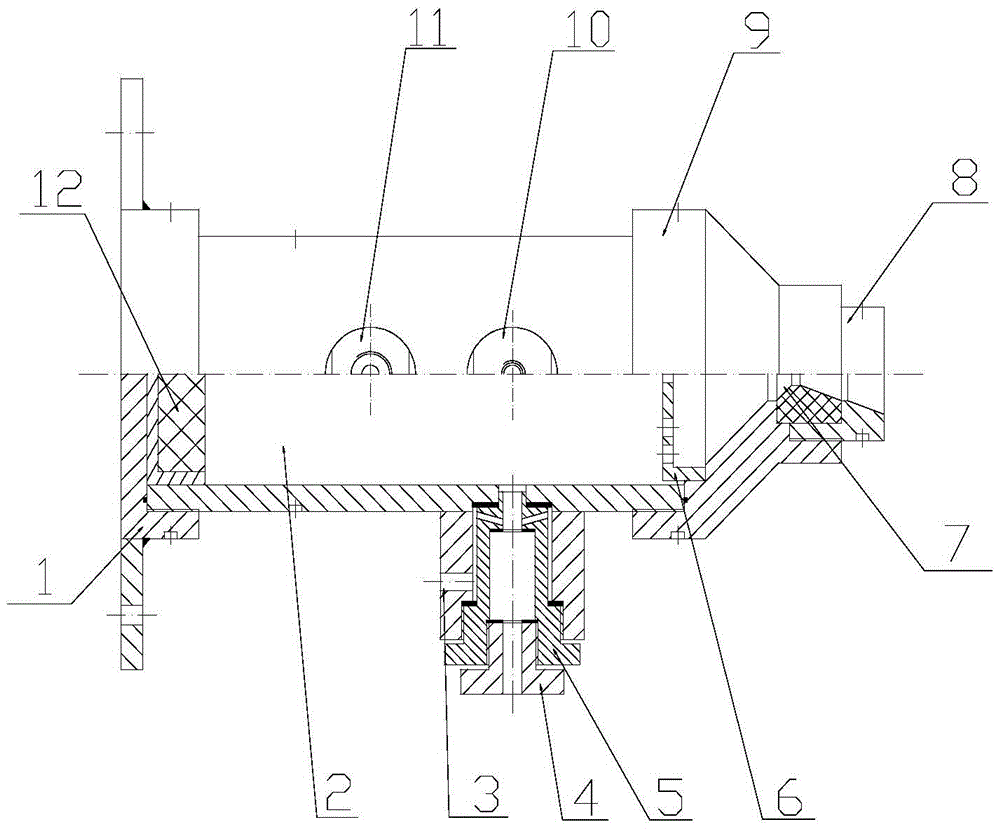

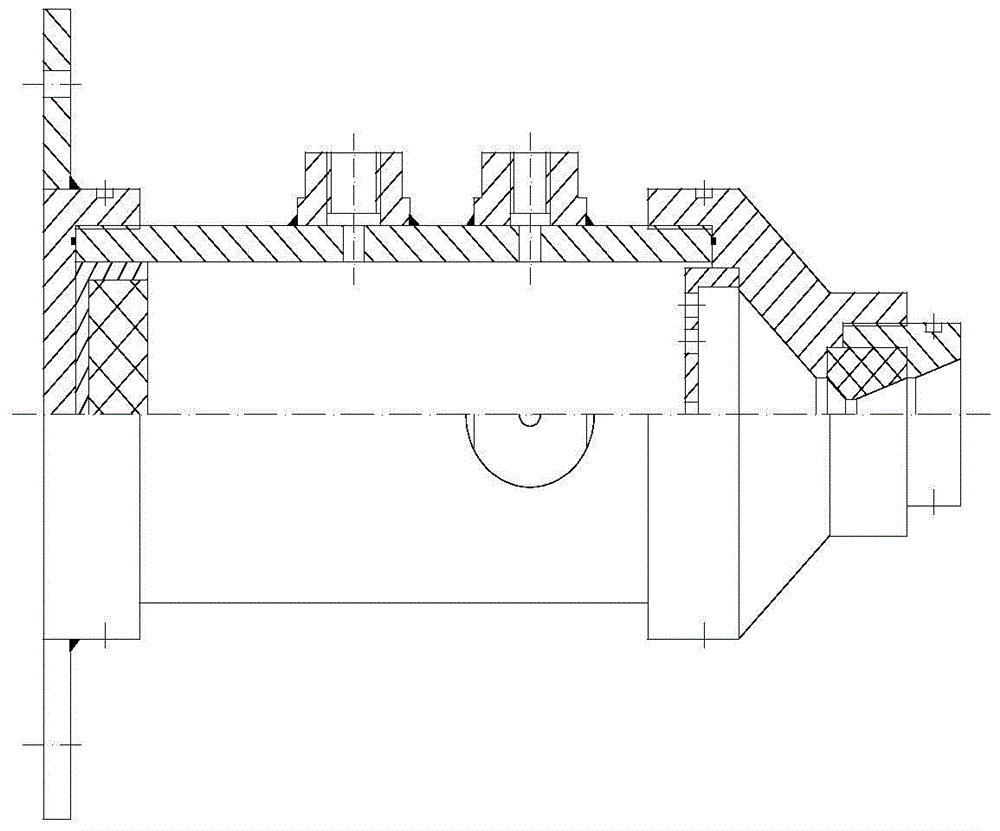

[0028] see Figure 1 to Figure 7 , the engine consists of front head 1, combustion chamber 2, air inlet 3, transparent window pressure screw 4, transparent window base 5, medicine baffle 6, nozzle seat 8, nozzle 7, rear head 9, temperature measuring hole 10. The pressure measuring hole 11 and the propellant 12 are composed; the combustion chamber 2 is a cylindrical structure, the two ends of the combustion chamber 2 are respectively connected with the front head 1 and the rear head 9 through threads, and the medicine baffle 6 is installed in the combustion chamber 2 At the inner rear end, the propellant 12 is placed in front of the medicine baffle 6; the medicine baffle 6 is an interference fit wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com