Composite soft magnetic material and preparation method thereof

A composite soft magnetic and nano-material technology, applied in the direction of inorganic material magnetism, can solve the problems of low insulation and voltage resistance, low resistivity, insufficient DC bias characteristics of devices, etc., and achieve the effect of improving insulation and voltage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

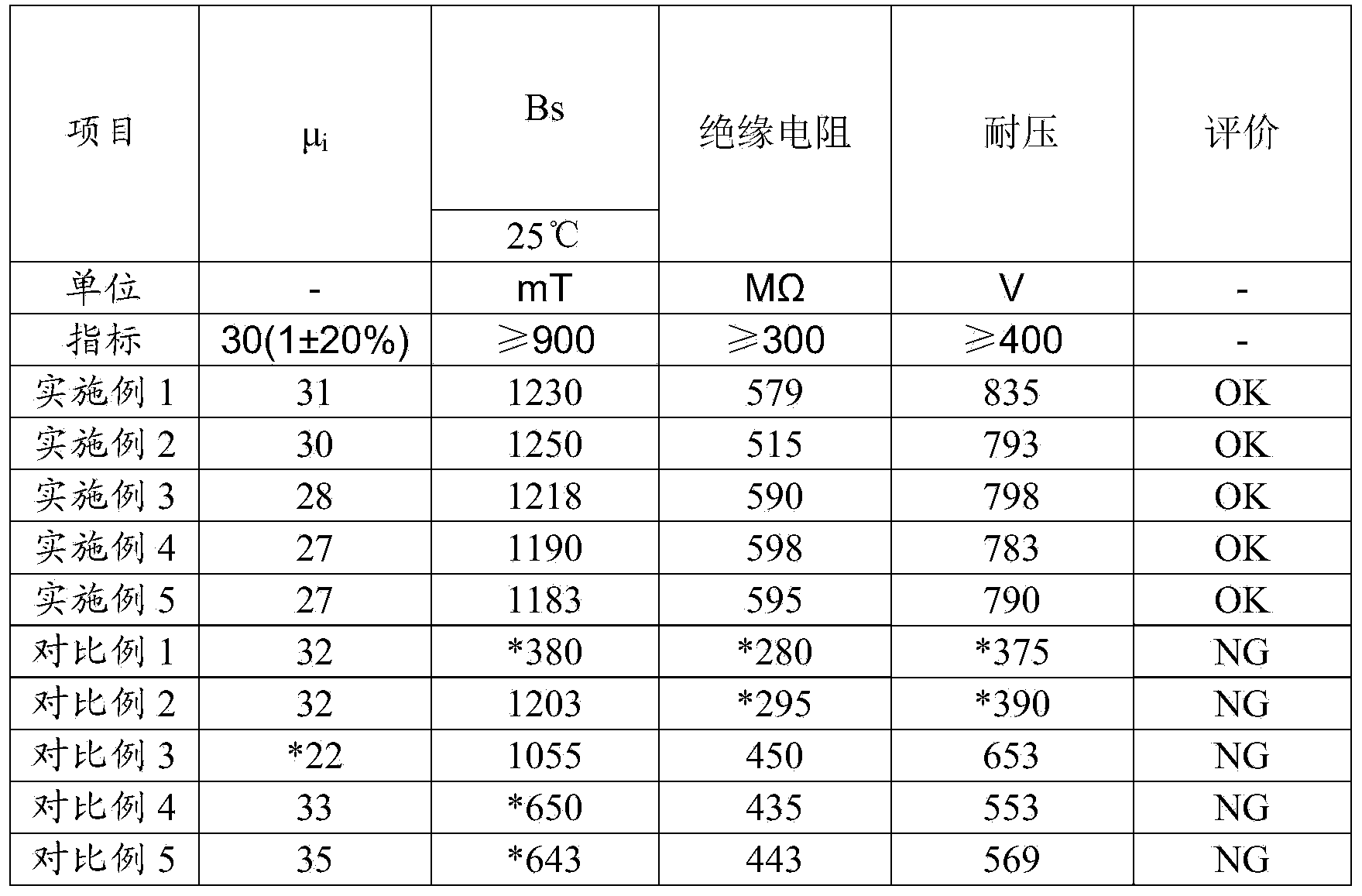

[0022] The embodiments of the present invention use composite soft magnetic material components with different proportions to prepare composite soft magnetic materials, and the composite soft magnetic materials prepared by the proportions of each embodiment and each comparative example are tested and evaluated respectively. Wherein Table 1 shows the composite soft magnetic material composition ratio of the embodiment and the comparative example, and the steps of the specific preparation method are as follows:

[0023] Step S1: Mixing; perform dry mixing according to the composition ratio in Table 1, and the mixing time is 60 to 90 minutes;

[0024] Step S2: pre-burning; the mixed materials are pre-fired in a nitrogen-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com