Lattice defect-containing difunctional bismuth subcarbonate catalyst and preparation method thereof

A kind of bismuth oxycarbonate catalyst, lattice defect technology, applied in the field of catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Put 1.5 g of pure-phase bismuth oxycarbonate in a vacuum treatment tube, and heat-treat it for 3 hours at a vacuum degree of 50 mmHg and a heat treatment temperature of 225° C. to obtain light black bismuth oxycarbonate. After the heat treatment, wait for it to cool down to room temperature, and put it in a sample tube for use.

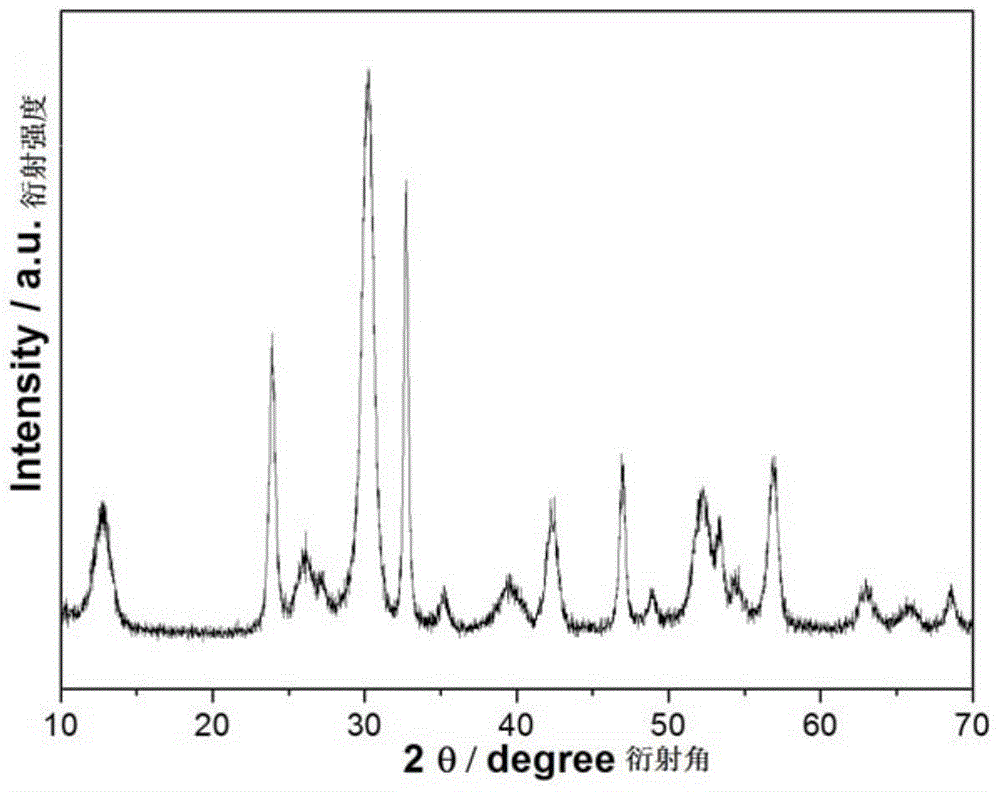

[0033] The present invention carries out XRD analysis to the bismuth oxycarbonate catalyst obtained after vacuum heat treatment, as figure 1 Shown, the bismuth oxycarbonate catalyst that present embodiment prepares has (BiO) 2 CO 3 phase and a small amount of bismuth elemental phase; the present invention carries out SEM scanning analysis to the bismuth oxycarbonate catalyst prepared by the present embodiment, and the result shows that the morphology of the bismuth oxycarbonate catalyst prepared by the present embodiment is consistent with the morphology of the pure phase bismuth oxycarbonate, so The vacuum heat treatment did not destroy the ...

Embodiment 2

[0036] Put 1.5g of pure-phase bismuth oxycarbonate in a vacuum treatment tube, and heat-treat it for 3 hours under the conditions of a vacuum degree of 50mmHg and a heat treatment temperature of 250°C to obtain black bismuth oxycarbonate. After the heat treatment, wait for it to cool down to room temperature, and put it in a sample tube for use.

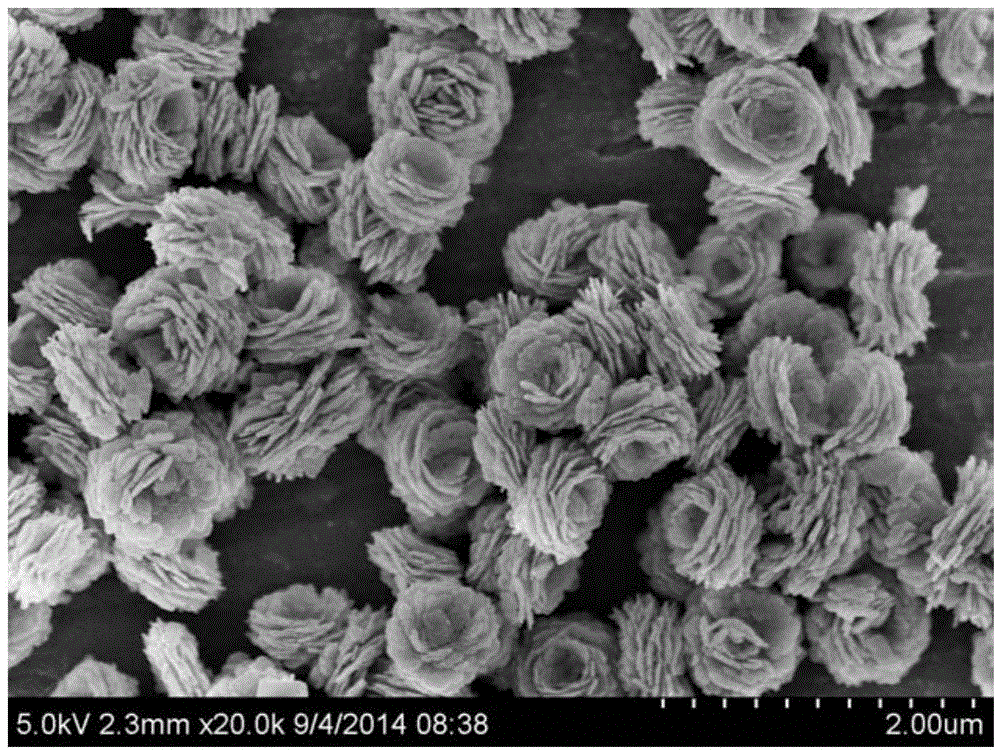

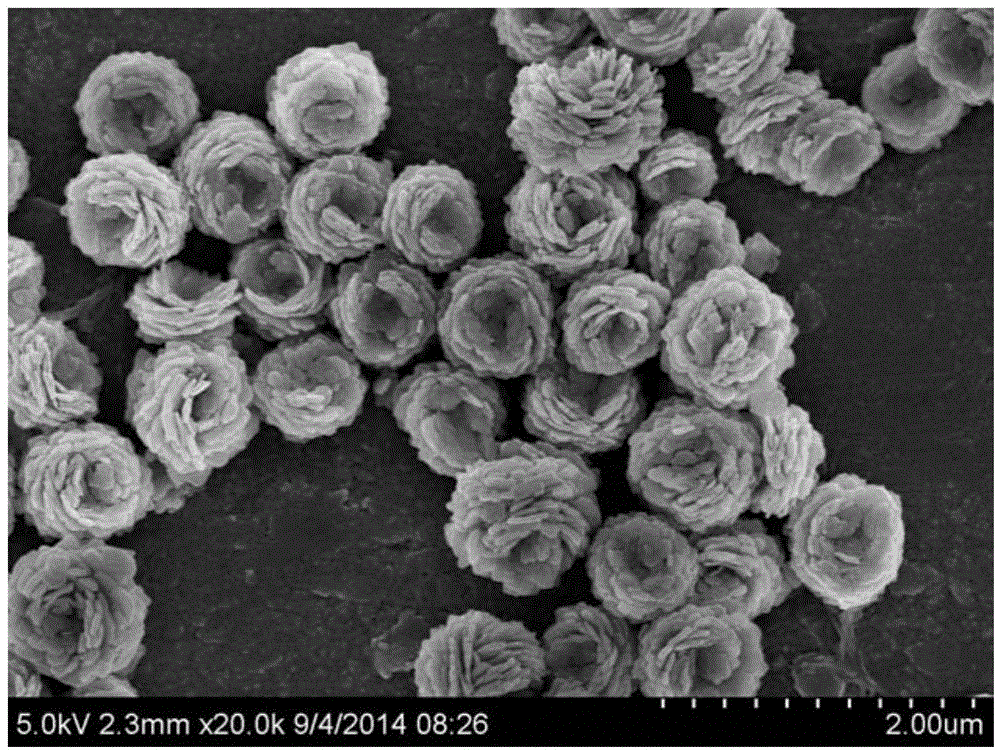

[0037] The present invention carries out XRD analysis to the bismuth oxycarbonate catalyst obtained after vacuum heat treatment, and the result shows that the bismuth oxycarbonate catalyst prepared by the present embodiment has (BiO) 2 CO 3 phase and bismuth single substance phase; the present invention carries out SEM scanning analysis to the bismuth oxycarbonate catalyst prepared by the present embodiment, as figure 2 , image 3 As shown, the result shows that the morphology of the bismuth oxycarbonate catalyst prepared by the present embodiment is consistent with the morphology of the pure phase bismuth oxycarbonate, so the vac...

Embodiment 3

[0040] Put 1.5g of pure-phase bismuth oxycarbonate in a vacuum treatment tube, and heat-treat it for 3 hours under the conditions of vacuum degree of 50mmHg and heat treatment temperature of 275°C to obtain black bismuth oxycarbonate. After the heat treatment, wait for it to cool down to room temperature, and put it in a sample tube for use.

[0041] The present invention carries out XRD analysis to the bismuth oxycarbonate catalyst obtained after vacuum heat treatment, as Figure 5 As shown, the result shows that the bismuth oxycarbonate catalyst prepared by the present embodiment has (BiO) 2 CO 3 phase and bismuth single substance phase; the present invention carries out SEM scanning analysis to the bismuth oxycarbonate catalyst prepared by the present embodiment, and the result shows that the morphology of the bismuth oxycarbonate catalyst prepared by the present embodiment is consistent with the morphology of the pure phase bismuth oxycarbonate, so vacuum heat treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com