Turbine Casting Method for Turbocharger for Gasoline Engine

A turbocharger and gasoline engine technology, which is applied in the field of metallurgical technology, can solve problems such as structural design and process route defects, and achieve the effects of high internal quality, high dimensional accuracy and high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

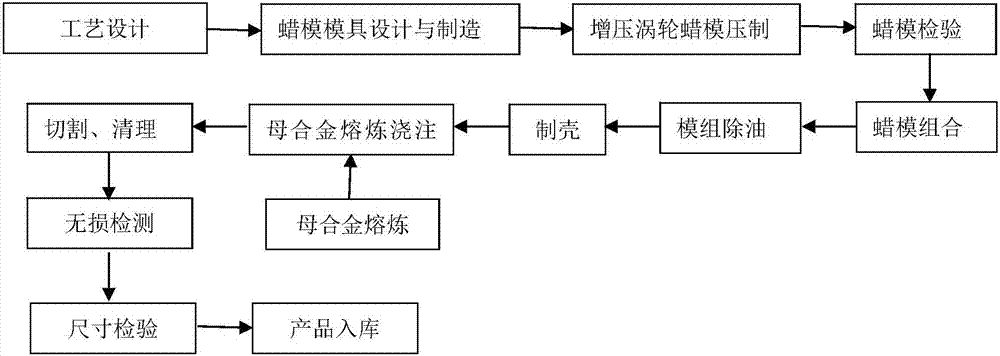

Image

Examples

Embodiment 1

[0024] A non-reserve investment casting process for a turbocharger for a gasoline engine, comprising the following steps:

[0025] 1) Wax mold design and manufacture; place the mold on the working surface of the wax press machine, adjust the height of the nozzle and the wax injection port

[0026] until consistent; open the mold, after checking that it is correct, spray a thin layer of atomized silicone oil, then close the mold, and align it with the wax injection nozzle;

[0027] 2) Compression and inspection of turbocharger wax molds: press the work button with both hands to press the wax molds; among them, the wax used for the wax molds in the wax mold pressing is filled with wax AB2066, and its shrinkage rate is controlled between 0.4% and 0.65%. Between, the ash content should be small. Pressing parameters are as follows: barrel area temperature 65°C; wax injection temperature 62°C; nozzle temperature 62°C; upper and lower template temperature 30°C; mold clamping pressur...

Embodiment 2

[0042] Basically the same as Example 1, the difference is: the pressing of the turbocharger wax mold: the temperature of the barrel area is 63°C; the temperature of wax injection is 62°C; the temperature of the nozzle is 60°C; the temperature of the upper and lower templates is 27°C; Pressure 40bar; injection pressure 8bar; injection time 40S; holding time 40S; parting agent: atomized silicone oil.

[0043] The master alloy is selected from the chemical composition shown in Table 2, and the balance is impurities.

[0044] Table 2 Unit: Mass %

[0045] Ni Cr Si P Fe mn Cu Sb Pb Bi 73.64 12.63 0.017 0.006 0.0270 0.0003 0.0026 <0.0001

[0046]The pouring of turbochargers for gasoline engines takes place on a three-chamber vacuum induction furnace. Vacuum induction furnace: the final baking temperature of the formwork is 1000°C, and the heat preservation is 3h; the superheating temperature of the alloy liquid is 1580°C; the pouring temperature...

Embodiment 3

[0048] Basically the same as Example 1, the difference is: the pressing of the turbocharger wax mold: the temperature of the barrel area is 68°C; the temperature of wax injection is 65°C; the temperature of the nozzle is 65°C; the temperature of the upper and lower templates is 32°C; Pressure 45bar; injection pressure 5bar; injection time 80S; holding time 90S; parting agent: atomized silicone oil.

[0049] The master alloy is selected from the chemical composition shown in Table 3, and the balance is impurities.

[0050] Table 3 Unit: mass percentage%

[0051] Ni Cr Si P Fe mn Cu Sb Pb Bi 73.65 12.67 0.041 0.006 0.0310 0.0020 0.0025 <0.0001

[0052] The pouring of turbochargers for gasoline engines is carried out on a three-chamber vacuum induction furnace or a rapid melting furnace. Vacuum induction furnace: the final baking temperature of the formwork is 1050°C, and the heat preservation is 3h; the superheating temperature of the alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com