High-calcium coal ash cement and preparation method thereof

A high-calcium fly ash and cement technology, which is applied in cement production and other directions, can solve the problems of reducing the strength of volume stabilized cement, and achieve the effects of reducing energy consumption, saving energy consumption and reducing the amount of clinker.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

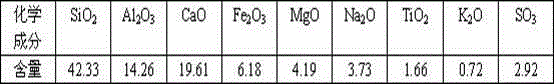

Image

Examples

preparation example Construction

[0033] The preparation method of high-calcium fly ash cement of the present invention may further comprise the steps:

[0034] 1) Ball milling: Portland cement clinker and desulfurized gypsum are mixed and ball milled to obtain a mixture;

[0035] 2) Mechanochemical excitation treatment: the mixture obtained in step 1) is mixed with high-calcium fly ash, silica fume, water glass and composite activator for ball milling to obtain high-calcium fly ash cement.

[0036] Each component of the high-calcium fly ash cement of the present invention can be subjected to mechanochemical activation treatment through ball milling to dissolve free calcium oxide in the fly ash, thereby solving the problem of volume stability caused by free calcium oxide. Among them, the composite activator (the mixture of triethanolamine and sodium sulfate) can efficiently stimulate the mechanochemical activation treatment under the ball milling condition, and the silica fume and water glass further assist an...

Embodiment 1

[0043] The weight percent of the high-calcium fly ash cement of the present embodiment is composed as follows:

[0044] Portland cement clinker 50%;

[0045] High calcium fly ash 40%;

[0046] Desulfurization gypsum 3.3%;

[0047] Silica fume 5.0%;

[0048] Water glass 1.0%;

[0049] Composite activator (a mixture of triethanolamine and sodium sulfate with a mass ratio of 1:3) 0.7%.

[0050] The preparation method is as follows: 1) Ball milling: first, mill cement clinker and desulfurized gypsum in a roller ball mill for 3 hours, and control the particle size of 300 mesh to be no more than 10%; 2) Mechanochemical excitation treatment: then high calcium fly ash, Silica fume, water glass, and composite activator are added together into a ball mill for 2 hours of ball milling to obtain high-calcium fly ash cement.

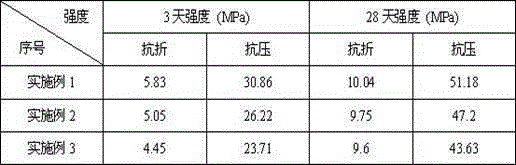

[0051] According to the method of GB / T17671-1999, the strength of the cement prepared in this example was tested, and the results are shown in Table 2. It can be...

Embodiment 2

[0053] The weight percent of the high-calcium fly ash cement of the present embodiment is composed as follows:

[0054] Portland cement clinker 40%;

[0055] High calcium fly ash 50%;

[0056] Desulfurization gypsum 3.2%;

[0057] Silica fume 4.9%;

[0058] Water glass 1.0%;

[0059] Compound activator (a mixture of triethanolamine and sodium sulfate with a mass ratio of 1:3) 0.9%.

[0060] The preparation method is as follows: 1) Ball milling: firstly, the cement clinker and desulfurized gypsum are ball-milled in a roller ball mill for 2 hours, and the 300-mesh sieve residue is controlled to be no more than 10%; 2) Mechanochemical excitation treatment: then the high-calcium fly ash, Silica fume, water glass and composite activator were added to the ball mill for 2h ball milling to obtain high calcium fly ash cement.

[0061] According to the method of GB / T17671-1999, the strength of the cement prepared in this example is tested. The results are shown in Table 2. It can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com