Self-leveling insulating castable for thermocouple wrapping

A thermocouple and self-leveling technology, which is applied in the field of self-leveling insulating castables for thermocouple wrapping, can solve the problems of losing the protective effect of U-shaped quartz tubes, reducing the insulation performance of refractory fillers, and poor moisture-proof performance of refractory fillers, etc., to achieve excellent self-leveling Good fluidity, moisture-proof effect, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

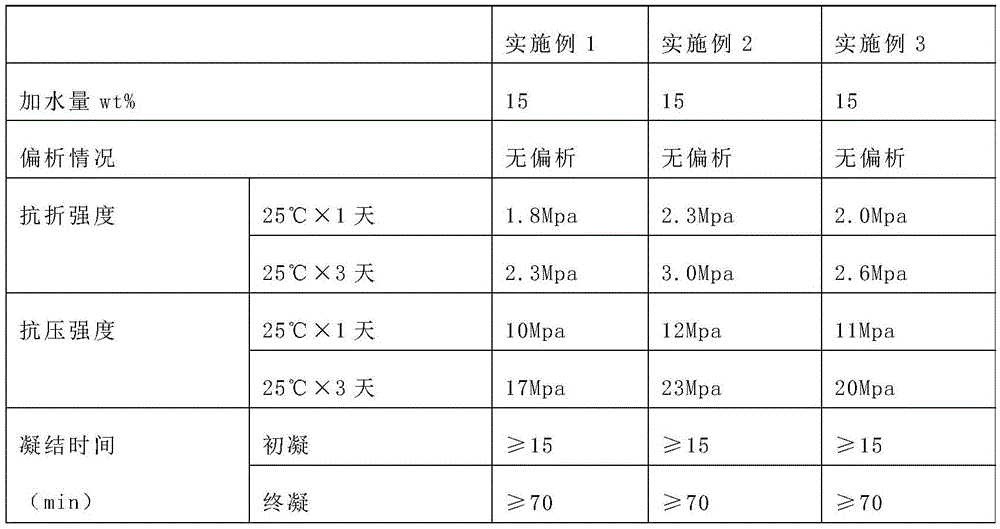

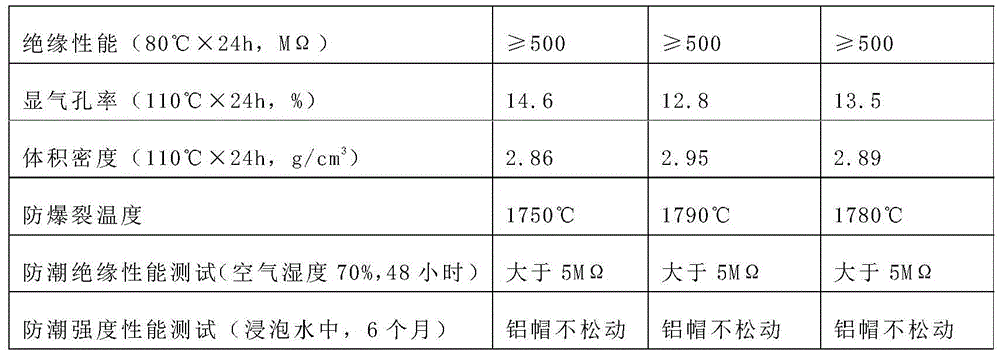

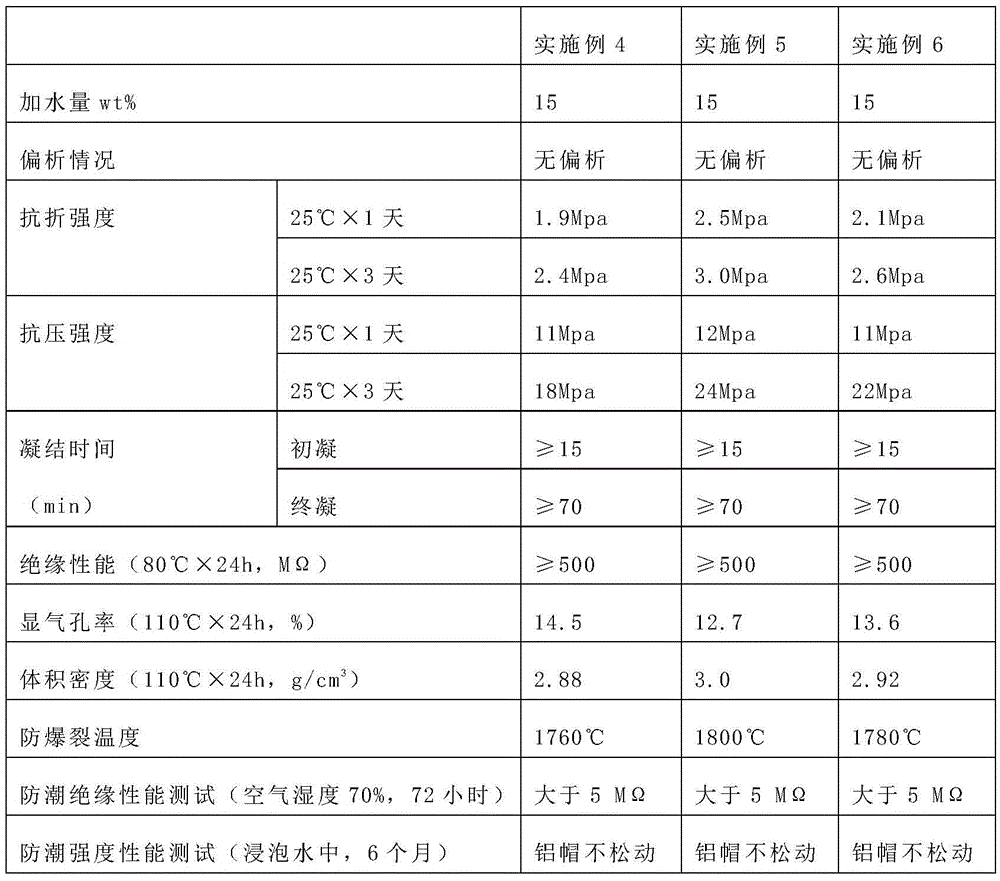

Embodiment 1

[0021] The self-leveling insulating castable for thermocouple wrapping in this embodiment is composed of the following components: brown corundum sand, brown corundum fine powder, alumina powder, fused alumina cement and water reducing agent.

[0022] The brown corundum sand is composed of 30-40 mesh brown corundum sand, 50-60 mesh brown corundum sand, 70-80 mesh brown corundum sand, 90-100 mesh brown corundum sand and 110-120 mesh brown corundum sand; 10 kg for brown corundum sand, 10 kg for 50-60 mesh brown corundum sand, 3 kg for 70-80 mesh brown corundum sand, 12 kg for 90-100 mesh brown corundum sand, 15 kg for 110-120 mesh brown corundum sand kilogram.

[0023] The brown corundum fine powder is composed of brown corundum fine powder with a particle size greater than 0 mesh and less than or equal to 180 mesh and brown corundum fine powder with a particle size of 200-325 mesh; the brown corundum fine powder with a particle size greater than 0 mesh and less than or equal to...

Embodiment 2

[0028] The self-leveling insulating castable for thermocouple wrapping in this embodiment is composed of the following components: brown corundum sand, brown corundum fine powder, alumina powder, fused alumina cement and water reducing agent.

[0029] The brown corundum sand is composed of 30-40 mesh brown corundum sand, 50-60 mesh brown corundum sand, 70-80 mesh brown corundum sand, 90-100 mesh brown corundum sand and 110-120 mesh brown corundum sand; 4 kg of brown corundum sand, 12 kg of brown corundum sand of 50-60 mesh, 5 kg of brown corundum sand of 70-80 mesh, 15 kg of brown corundum sand of 90-100 mesh and 17 kg of brown corundum sand of 110-120 mesh kilogram.

[0030] The brown corundum fine powder is composed of brown corundum fine powder with a particle size greater than 0 mesh and less than or equal to 180 mesh and brown corundum fine powder with a particle size of 200-325 mesh; the brown corundum fine powder with a particle size greater than 0 mesh and less than or...

Embodiment 3

[0035] The self-leveling insulating castable for thermocouple wrapping in this embodiment is composed of the following components: brown corundum sand, brown corundum fine powder, alumina powder, fused alumina cement and water reducing agent.

[0036] The brown corundum sand is composed of 30-40 mesh brown corundum sand, 50-60 mesh brown corundum sand, 70-80 mesh brown corundum sand, 90-100 mesh brown corundum sand and 110-120 mesh brown corundum sand; 12 kg for brown corundum sand, 8 kg for 50-60 mesh brown corundum sand, 5 kg for 70-80 mesh brown corundum sand, 10 kg for 90-100 mesh brown corundum sand and 13 kg for 110-120 mesh brown corundum sand kilogram.

[0037] The brown corundum fine powder is composed of brown corundum fine powder with a particle size greater than 0 mesh and less than or equal to 180 mesh and brown corundum fine powder with a particle size of 200-325 mesh; the brown corundum fine powder with a particle size greater than 0 mesh and less than or equal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com