LDPE (low-density polyethylene) foaming heteromorphic material and preparation method thereof

A technology for foamed sheets and heterosexual materials, which is applied in the field of LDPE foamed deformed materials and their preparation, can solve the problems of unenvironmental protection, poor elasticity, poor burst resistance, poor folding resistance and puncture resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

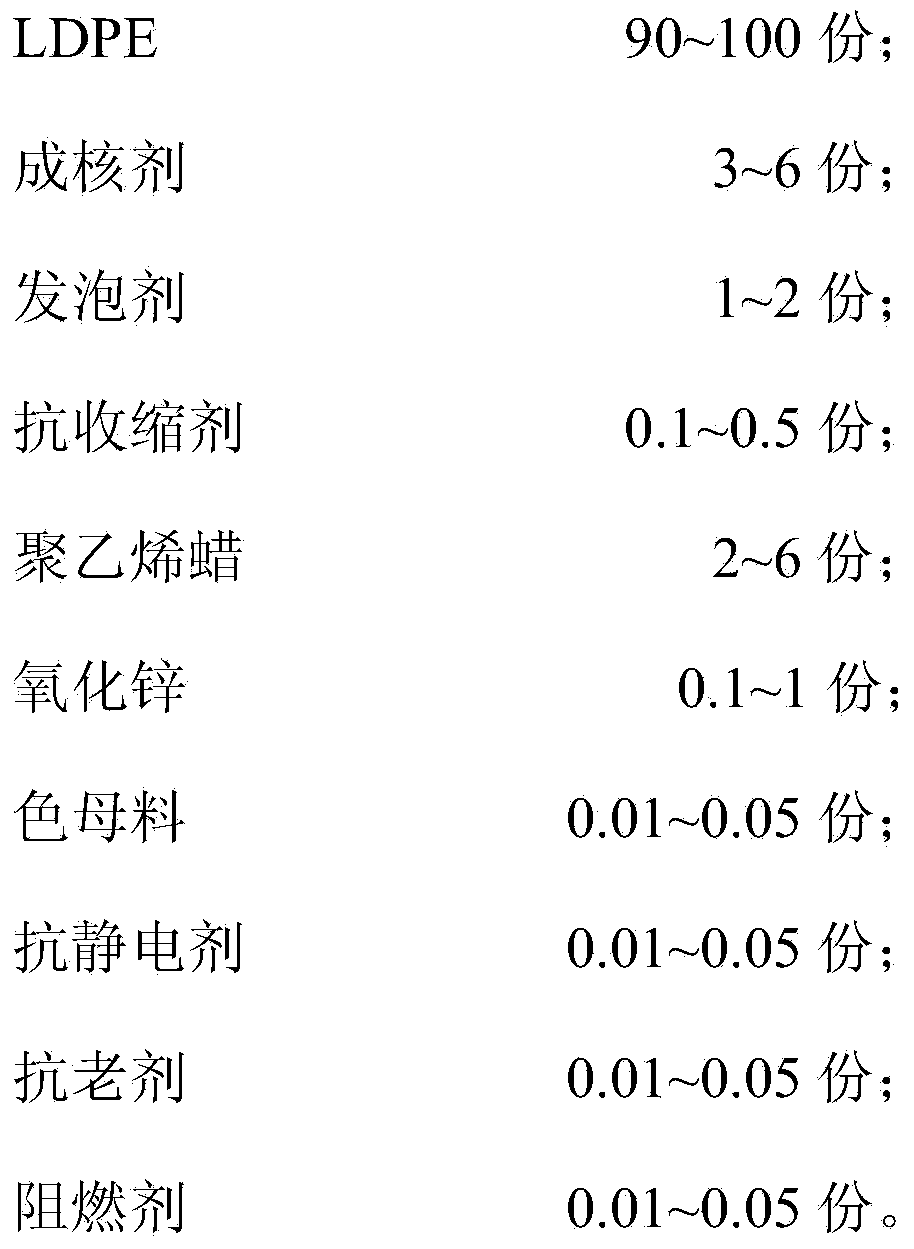

[0020] Embodiment 1: a kind of LDPE foaming special-shaped material, by mass parts, comprises the following components:

[0021]

[0022] A method for preparing the above-mentioned LDPE foamed profiled material, comprising the following steps:

[0023] In parts by mass, add 90 parts of LDPE, 3 parts of nucleating agent and 2 parts of polyethylene wax into the barrel of the extruder, mix at 125°C for 5 minutes, add 0.1 part of zinc oxide, 0.01 part of color masterbatch, antistatic 0.01 part of anti-aging agent, 0.01 part of anti-aging agent, 0.01 part of flame retardant, continue mixing for 2 minutes, heat 1 part of foaming agent and 0.1 part of anti-shrinkage agent to 105 ° C, and add them to the material at a pressure of 10 MPa with a high-pressure metering pump In the cylinder, heat to 150°C and mix for 4 minutes to disperse the components evenly, cool, extrude through the filter, foam, form, cool and draw, and flatten to obtain LDPE foamed special-shaped materials;

[0...

Embodiment 2

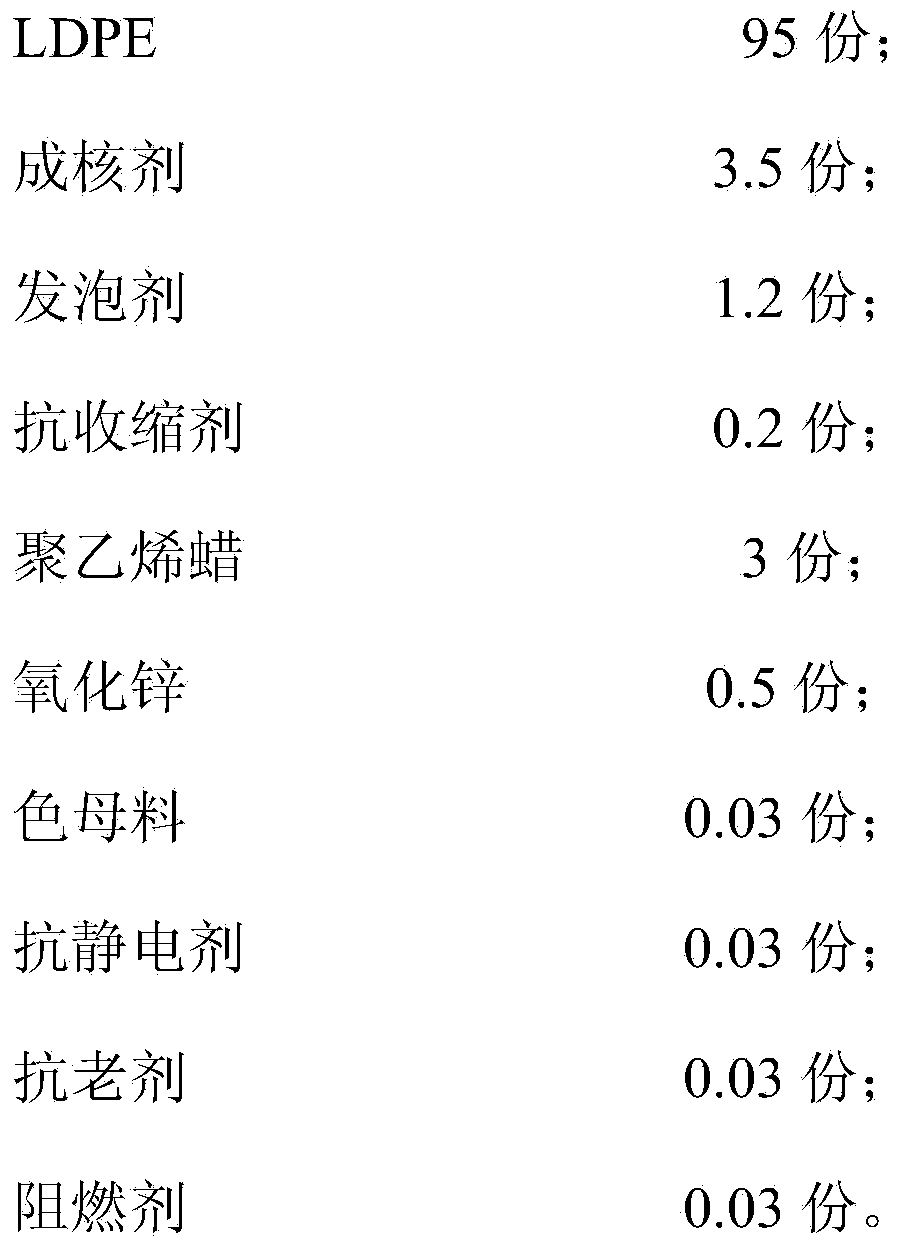

[0025] Embodiment 2: a kind of LDPE foaming special-shaped material, by mass parts, comprises the following components:

[0026]

[0027] A method for preparing the above-mentioned LDPE foamed profiled material, comprising the following steps:

[0028] In parts by mass, add 95 parts of LDPE, 3.5 parts of nucleating agent and 3 parts of polyethylene wax into the barrel of the extruder, mix at 130°C for 6 minutes, add 0.5 parts of zinc oxide, 0.03 parts of color masterbatch, antistatic 0.03 parts of anti-aging agent, 0.03 parts of anti-aging agent, 0.03 parts of flame retardant, continue mixing for 2.5 minutes, heat 1.2 parts of foaming agent and 0.2 parts of anti-shrinkage agent to 110 ° C, and add them to the In the barrel, heat to 160°C and mix for 5 minutes to disperse the components evenly, cool, extrude through the filter, foam, form, cool and draw, and flatten to obtain LDPE foamed special-shaped materials;

[0029] After the rolled foamed sheet is left to stand for 1...

Embodiment 3

[0030] Embodiment 3: a kind of LDPE foaming special-shaped material, by mass parts, comprises the following components:

[0031]

[0032] A method for preparing the above-mentioned LDPE foamed profiled material, comprising the following steps:

[0033] The specific process of step (1) is: in parts by mass, add 100 parts of LDPE, 6 parts of nucleating agent and 6 parts of polyethylene wax into the barrel of the extruder, mix at 135°C for 7 minutes, add 1 part of zinc oxide, 0.05 part of color masterbatch, 0.05 part of antistatic agent, 0.05 part of anti-aging agent, 0.05 part of flame retardant, continue mixing for 3 minutes, heat 2 parts of foaming agent and 0.5 part of anti-shrinkage agent to 115 °C, and measure with high pressure respectively The pump is added into the barrel at a pressure of 15MPa, heated to 170°C and mixed for 6 minutes, so that the components are uniformly dispersed, cooled, extruded through the filter, foamed, formed, cooled and drawn, and flattened t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com