Composite nano coating for oil casing threads and preparation method and use method of composite nano coating

A nano-coating, oil-casing technology, applied in the direction of anti-corrosion coatings, polyester coatings, polyacetal coatings, etc., can solve the problems of inaccurate amount of thread grease, low production efficiency of copper plating, environmental hazards, etc., to increase the reliability of the connection performance, protection from corrosion, and improvement of construction efficiency

Inactive Publication Date: 2015-03-11

XIAN RUILIN SURFACE ENG

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the solution of copper plating and phosphating process has great environmental hazards. The thread grease often contains heavy metals such as lead, copper, and zinc, which flow out during the making and breaking process, causing serious pollution to the surrounding environment. Accumulation in oil and gas wells requires frequent cleaning operations, which greatly increases production costs. In addition, thread grease will harden due to low temperature in cold regions, resulting in increased stress on oil and casing.

The application of thread compound is now mainly done manually by Inoue, the amount of thread compound is often inaccurate and the efficiency is low

The production efficiency of copper plating is low, the economy is not good, and large-scale use cannot be realized

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

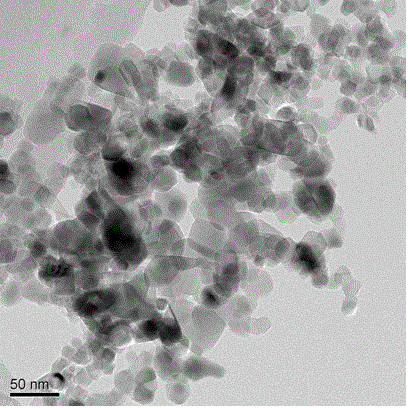

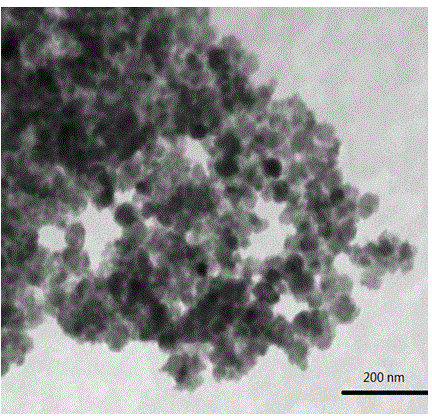

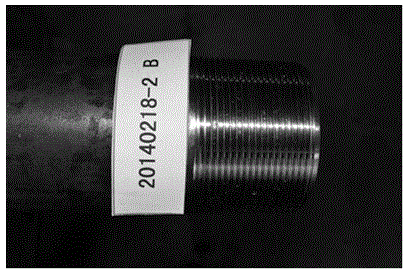

The invention discloses a composite nano coating for oil casing threads. The composite nano coating comprises the following components: film-forming resin, an organic solvent, nano lubrication packing, a dispersing agent and a defoaming agent. A preparation method comprises the following steps: 1) uniformly mixing the nano lubrication packing and the dispersing agent; 2) grinding the mixture and the organic solvent, and uniformly mixing; 3) adding the film-forming resin, and uniformly mixing; 4) continuously adding the solvent till appropriate concentration, and uniformly mixing; and 5) sealing and storing the prepared coating. The use method of the coating comprises the following steps: 1) pretreating the oil casing threads, including decontamination, degreasing, washing with water, pickling and sand blasting or phosphorization; 2) coating or spraying the uniformly mixed coating on the surfaces of the threads; and 3) curing the coating at the room temperature. The composite nano coating disclosed by the invention is simple in preparation process, convenient to construct and low in cost, thread gluing is effectively avoided, and the threads are prevented from corrosion.

Description

technical field The invention belongs to the technical field of petroleum machinery, and in particular relates to a composite nano-coating for oil casing thread and its preparation and use method, which can effectively prevent oil casing from sticking during use and play a role of corrosion protection. Background technique The failure phenomenon of sticky fasteners is a phenomenon that when the surfaces of materials slide or roll relative to each other, the surfaces of materials in contact with each other are fused due to cold welding, resulting in surface tearing. The thread sticking of the oil casing joint is that when the thread of the oil casing is threaded on and off, the threads in contact with each other are not in ideal smooth contact, but have certain roughness and shape and size deviations. Under the action of contact pressure, The actual contact area is much lower than the theoretical contact area, causing the pressure in the local area of the contact surface to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D159/00C09D161/20C09D163/00C09D161/06C09D167/00C09D167/08C09D133/00C09D175/04C09D127/18C09D5/08

CPCC09D159/00C08K2201/011C08L2205/03C09D5/08C09D7/20C09D7/61C09D7/65C09D7/67C09D7/68C09D161/20C09D163/00C08L101/00C08L27/18C08K3/04C08K2003/3009C08K3/34C08K3/2279

Inventor 张坤申昭熙

Owner XIAN RUILIN SURFACE ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com