Tetrafluoropropene composition with good lubricant compatibility and preparation method thereof

A tetrafluoropropene and lubricant technology, which is applied in the field of tetrafluoropropene composition and its preparation, can solve the problems of increasing equipment investment and energy consumption, affecting the degree of two-phase mixing, affecting the heat transfer performance of refrigerants, etc. The effect of low flammability, low flammability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

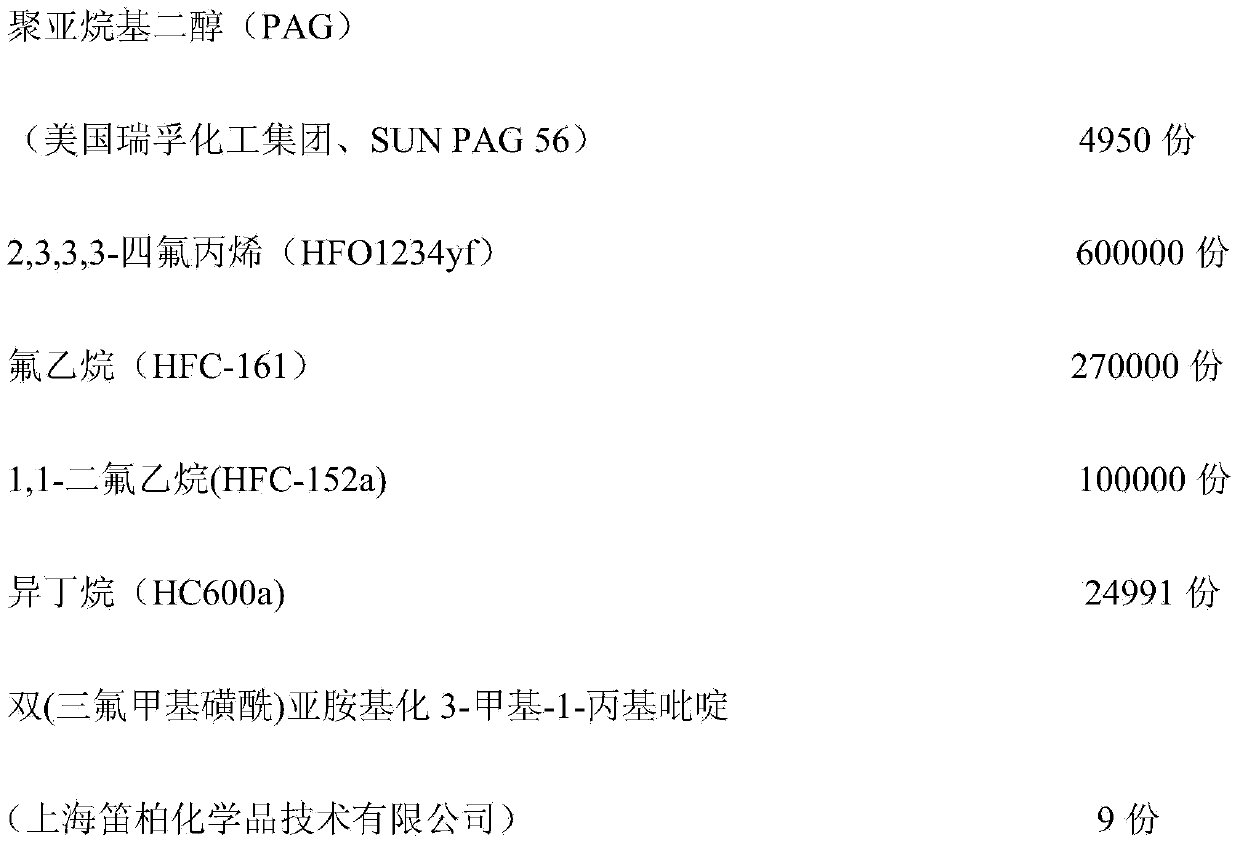

[0031] A kind of tetrafluoropropene composition with good lubricant compatibility, by every 1g, formula is as follows:

[0032]

[0033]

[0034] Its preparation method is as follows:

[0035] The preparation of step (1) nano-lubricant

[0036] In a stirred reactor, disperse 48.75 parts of fluorine-modified Ni-containing hydrotalcite into 1,000,000 parts of ethanol according to the proportion, then add 1.25 parts of KH550 silane coupling agent, react at 25°C for 15 hours, filter to remove ethanol, and then add 4950 Parts of polyalkylene glycol (PAG) were reacted at 25°C for 15 hours to obtain a nano-lubricant.

[0037] Step (2) mixing in the high-throughput microchannel glass reactor

[0038] Mix the nano-lubricant prepared in step (1) with 600,000 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 270,000 parts of fluoroethane (HFC-161), and 100,000 parts of 1,1-difluoroethane (HFC-152a), 24991 parts of isobutane (HC600a), 9 parts of bis(trifluoromethylsulfonyl)imidate...

Embodiment 2

[0040] A kind of tetrafluoropropene composition with good lubricant compatibility, by every part of 1Kg, formula is as follows:

[0041]

[0042] Its preparation method is as follows:

[0043] The preparation of step (1) nano-lubricant

[0044] In a stirred reactor, disperse 0.00497 parts of fluorine-modified Ni-containing hydrotalcites into 1000 parts of ethanol according to the proportion, then add 0.00002 g parts of KH570 silane coupling agent, react at room temperature for 10 hours, filter to remove ethanol, and then add 0.99501 Parts of polyalkylene glycol (PAG), react at room temperature for 10 hours, and obtain nano-lubricant.

[0045] Step (2) mixing in the high-throughput microchannel glass reactor

[0046] The nano-lubricant prepared in step (1) is mixed with 200 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 600 parts of fluoroethane (HFC-161), 150 parts of 1,1-difluoroethane (HFC-152a), 48.992 parts of isobutane (HC600a), 0.008 parts of bis(trifluoromethyls...

Embodiment 3

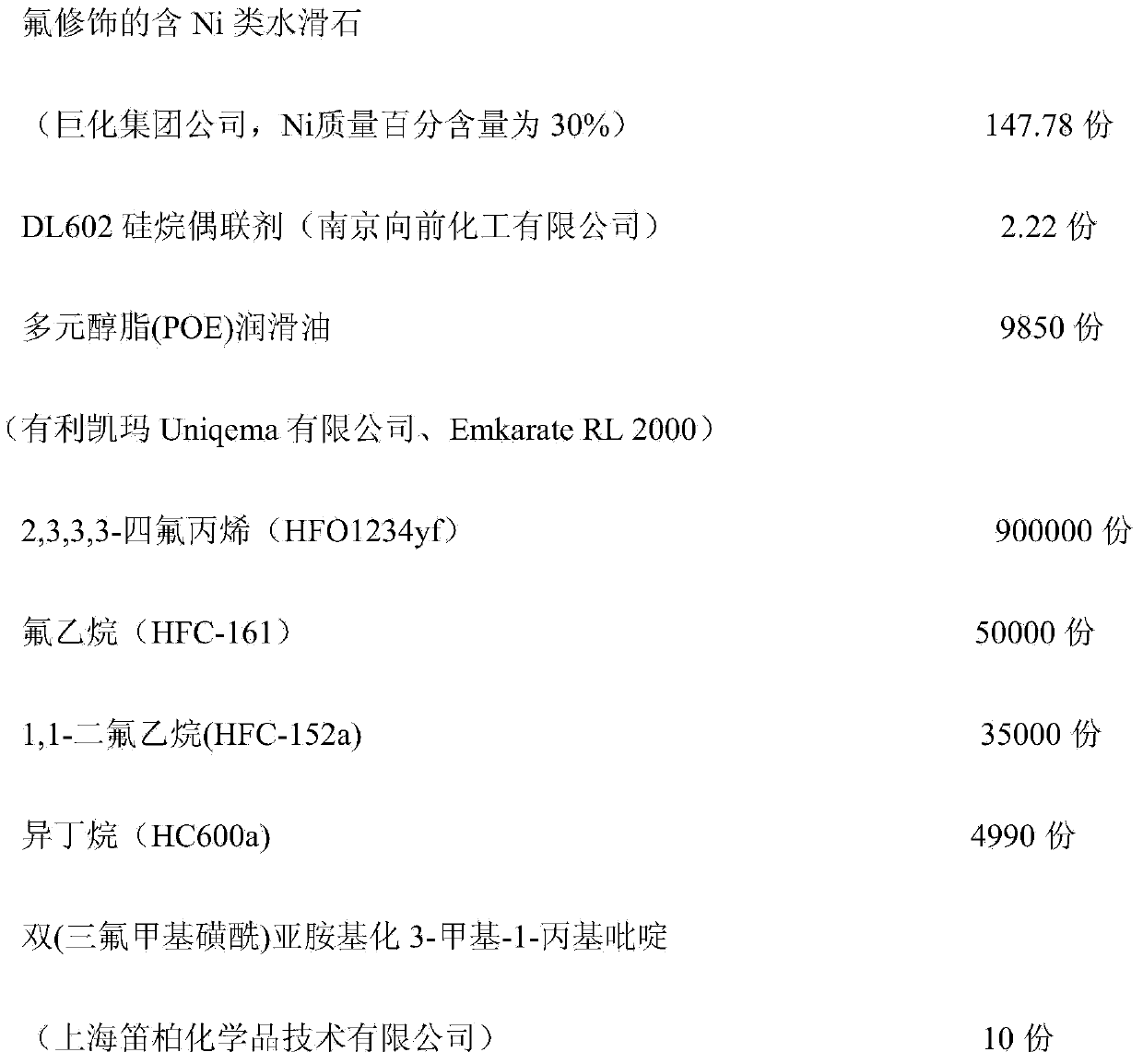

[0048] A kind of tetrafluoropropene composition with good lubricant compatibility, by every 1g, formula is as follows:

[0049]

[0050] Its preparation method is as follows:

[0051] The preparation of step (1) nano-lubricant

[0052] In a stirred reactor, disperse 147.78 parts of fluorine-modified Ni-containing hydrotalcites into 1,000,000 parts of ethanol according to the proportion, then add 2.12 parts of DL602 silane coupling agent, react at room temperature for 20 hours, filter to remove ethanol, and then add 9850 Parts of polyol ester (POE) lubricating oil, react at room temperature for 20h to obtain nano-lubricant.

[0053] Step (2) mixing in the high-throughput microchannel glass reactor

[0054] Mix the nano-lubricant prepared in step (1) with 900,000 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 50,000 parts of fluoroethane (HFC-161), and 35,000 parts of 1,1-difluoroethane (HFC-152a), 4990 parts of isobutane (HC600a), 10 parts of bis(trifluoromethylsulfonyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com