Leaching method for recovering lead from lead oxide ores, and its leaching agent

A leaching agent, lead oxide technology, applied in the improvement of process efficiency, photography process, instruments, etc., can solve the problems of instability, low solubility, and inappropriateness, and achieve the effect of low process cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

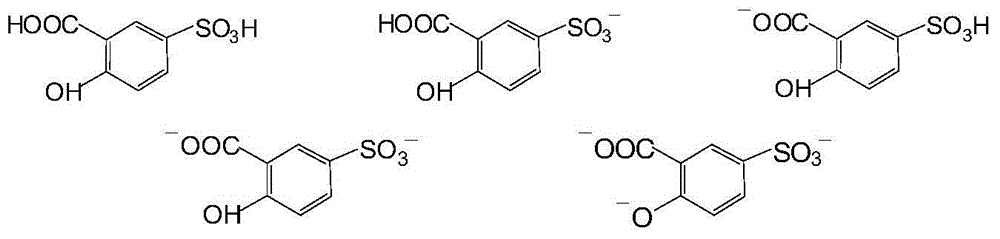

Image

Examples

Embodiment 1

[0021] The embodiment of the present invention provides a leaching agent for recovering lead in lead oxide ore. The leaching agent is mainly formed by uniformly mixing 5-sulfosalicylic acid and water, and the concentration of 5-sulfosalicylic acid is 0.2mol / L. The oxidized lead ore with a lead grade of 40% is leached, the leaching temperature is 30°C, the weight percentage of the ore particle size is less than 65 μm is 80%, and the leaching agent of 5-sulfosalicylic acid and the lead oxide ore powder are mixed according to the ratio of 20:1 The mass liquid-solid ratio is mixed, fully stirred for 35 minutes, and the leaching rate of lead is about 91.1%.

Embodiment 2

[0023] The embodiment of the present invention provides a leaching agent for recovering lead in lead oxide ore. The leaching agent is mainly formed by uniformly mixing 5-sulfosalicylic acid and water, and the concentration of 5-sulfosalicylic acid is 0.4mol / L. The oxidized lead ore with a lead grade of 47% is leached, the leaching temperature is 35°C, the weight percentage of the ore particle size is less than 65 μm is 85%, and the leaching agent of 5-sulfosalicylic acid and the lead oxide ore powder are mixed according to the ratio of 20:1 The mass liquid-solid ratio is mixed, fully stirred for 45 minutes, and the leaching rate of lead is about 94.8%.

Embodiment 3

[0025] The embodiment of the present invention proposes a leaching method for recovering lead in oxidized lead ore. The method is specifically as follows: crushing and grinding the lead oxide ore with a lead grade of 35%, and the weight percentage of the ore with a particle size of less than 65 μm is 80%; Mix with lead oxide ore powder according to the mass liquid-solid ratio of 15:1, and fully stir for 40 minutes, wherein the leaching temperature is controlled at 25°C; a lead-containing solution suitable for the next step of extraction and electrowinning is obtained. The lead leaching rate is about 96.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com