Zr-Ti-Cu-Ni-Be-Co bulk amorphous alloy material and preparation method thereof

A zr-ti-cu-ni-be-co, amorphous alloy technology, applied in the field of Zr-Ti-Cu-Ni-Be-Co bulk amorphous alloy material and its preparation, to improve the fracture strength, improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

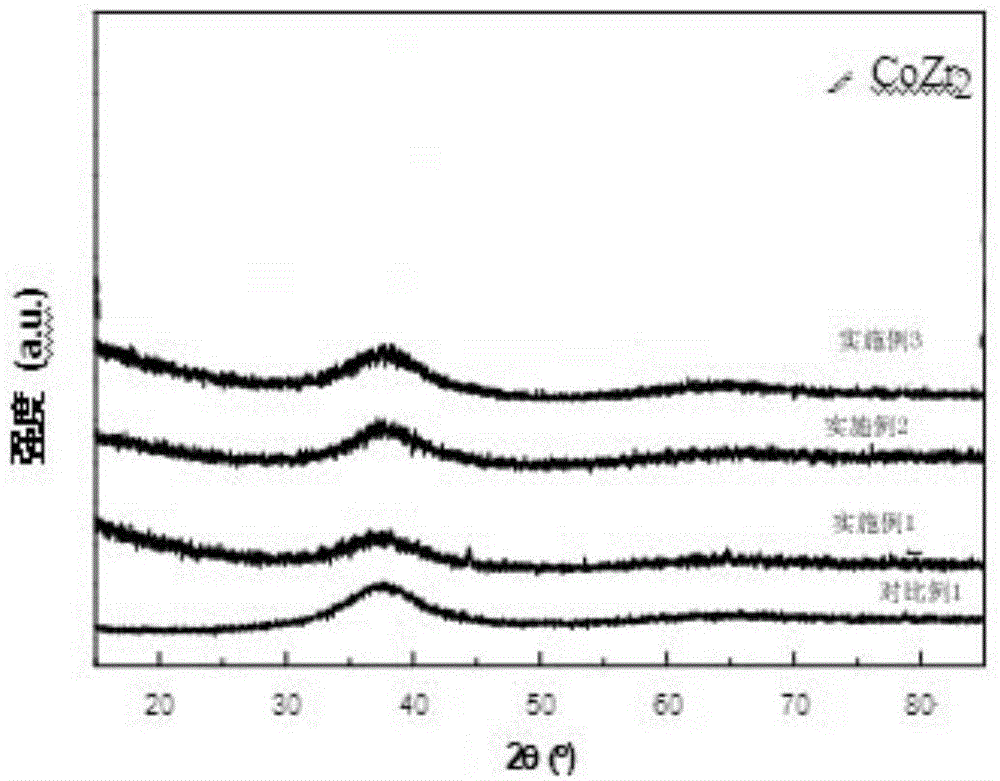

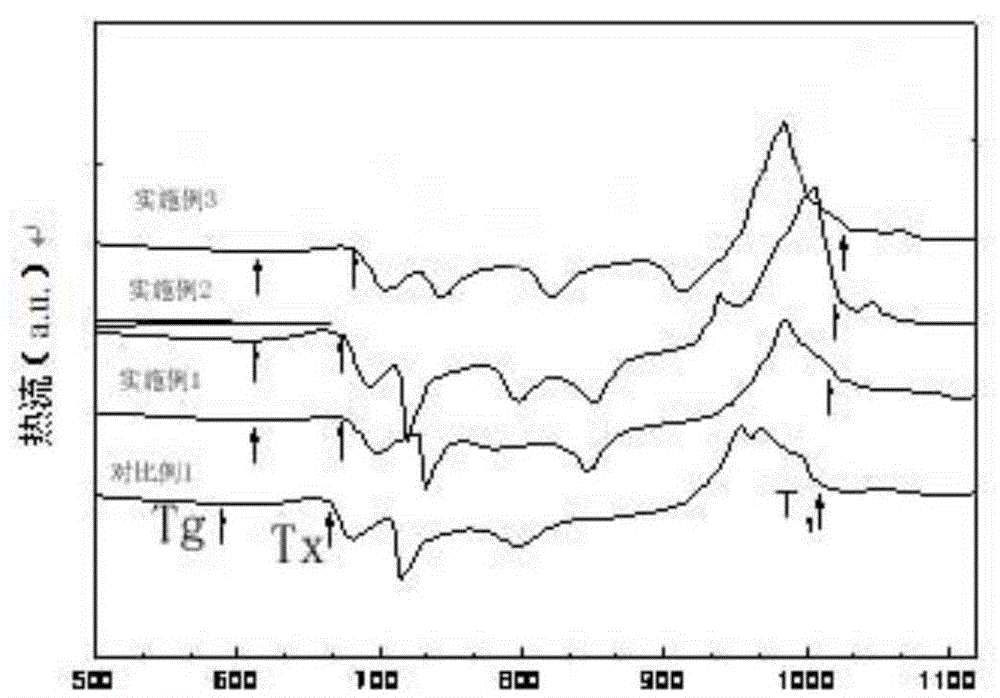

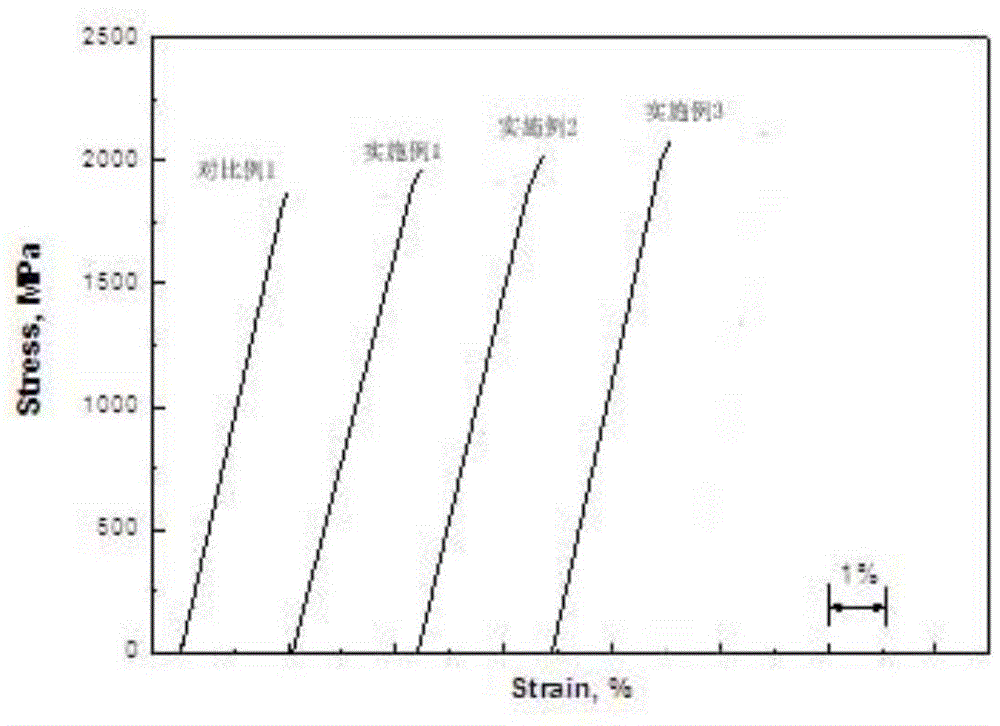

[0024] A Zr-Ti-Cu-Ni-Be-Co bulk amorphous alloy material is composed of the following substances according to the following atomic percentages: zirconium 38%, titanium 17%, copper 12.5%, nickel 5%, beryllium 22.5%, cobalt 5%.

[0025] Preparation:

[0026] a. Ingredients: Select high-purity zirconium, titanium, beryllium, copper, nickel and cobalt bulk metals as raw materials, according to the following atomic percentages: zirconium 38%, titanium 17%, copper 12.5%, nickel 5%, beryllium 22.5% , Cobalt 5% for batching;

[0027] b. Removing the surface oxide layer: Polish the bulk metal surface of zirconium, titanium, beryllium, copper, nickel and cobalt to remove the oxide layer on the surface. The bulk metal is cleaned in acetone solution, and then cleaned by ultrasonic wave for 5 minutes;

[0028] c. Melting: vacuumize the vacuum arc melting furnace and fill it with 10 5 Pa high-purity argon gas is used as a protective atmosphere, and then the bulk metals of zirconium, tit...

Embodiment 2

[0032] A Zr-Ti-Cu-Ni-Be-Co bulk amorphous alloy material is composed of the following substances according to the following atomic percentages: zirconium 38%, titanium 17%, copper 12.5%, beryllium 22.5%, cobalt 10%.

[0033] Preparation:

[0034] a. Batching: Select high-purity zirconium, titanium, beryllium, copper and cobalt bulk metals as raw materials, according to the following atomic percentages: zirconium 38%, titanium 17%, copper 12.5%, beryllium 22.5%, cobalt 10% for batching ;

[0035] b. Remove the oxide layer on the surface: polish the surface of the bulk metal of zirconium, titanium, beryllium, copper and cobalt, remove the oxide layer on the surface, and place the bulk metal of zirconium, titanium, beryllium, copper and cobalt after removing the oxide layer. Wash in acetone solution, and then pass through ultrasonic cleaning for 5 minutes;

[0036] c. Melting: vacuumize the vacuum arc melting furnace and fill it with 10 5 Pa high-purity argon gas is used as a ...

Embodiment 3

[0040] A Zr-Ti-Cu-Ni-Be-Co bulk amorphous alloy material is composed of the following substances according to the following atomic percentages: zirconium 38%, titanium 17%, copper 10.5%, beryllium 22.5%, cobalt 12%.

[0041] Preparation:

[0042] a. Batching: select high-purity zirconium, titanium, beryllium, copper and cobalt bulk metals as raw materials, according to the following atomic percentages: zirconium 38%, titanium 17%, copper 10.5%, beryllium 22.5%, cobalt 12% for batching ;

[0043] b. Remove the oxide layer on the surface: polish the surface of the bulk metal of zirconium, titanium, beryllium, copper and cobalt, remove the oxide layer on the surface, and put the bulk metal of zirconium, titanium, beryllium, copper and cobalt after removing the oxide layer. Wash in acetone solution, and then pass through ultrasonic cleaning for 5 minutes;

[0044] c. Melting: vacuumize the vacuum arc melting furnace and fill it with 10 5 Pa high-purity argon gas is used as a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com