High-speed heavy-load mute tow chain

A quiet, high-speed technology, applied in the field of towlines, can solve the problems of high noise, high speed and heavy loads of towlines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

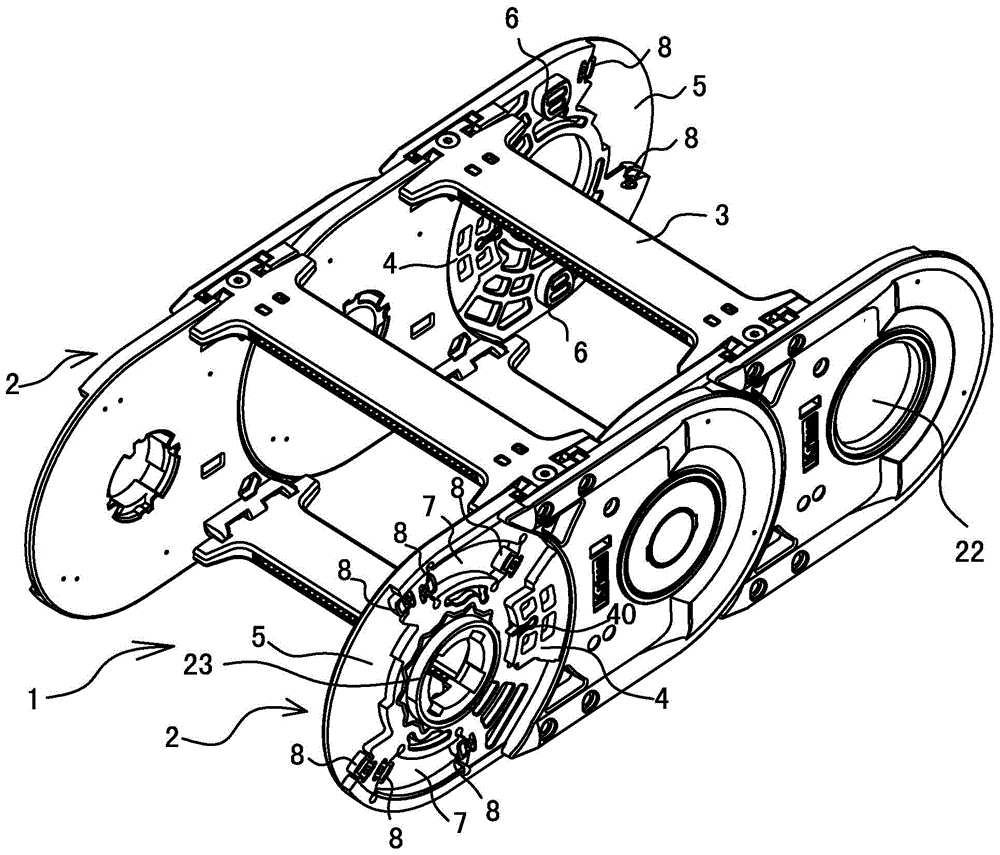

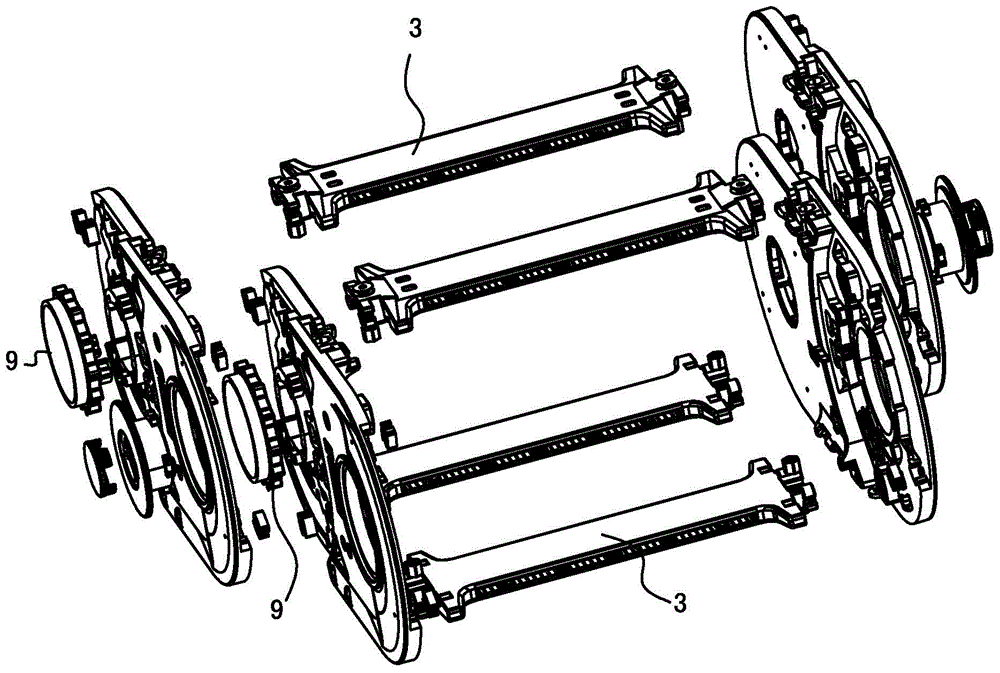

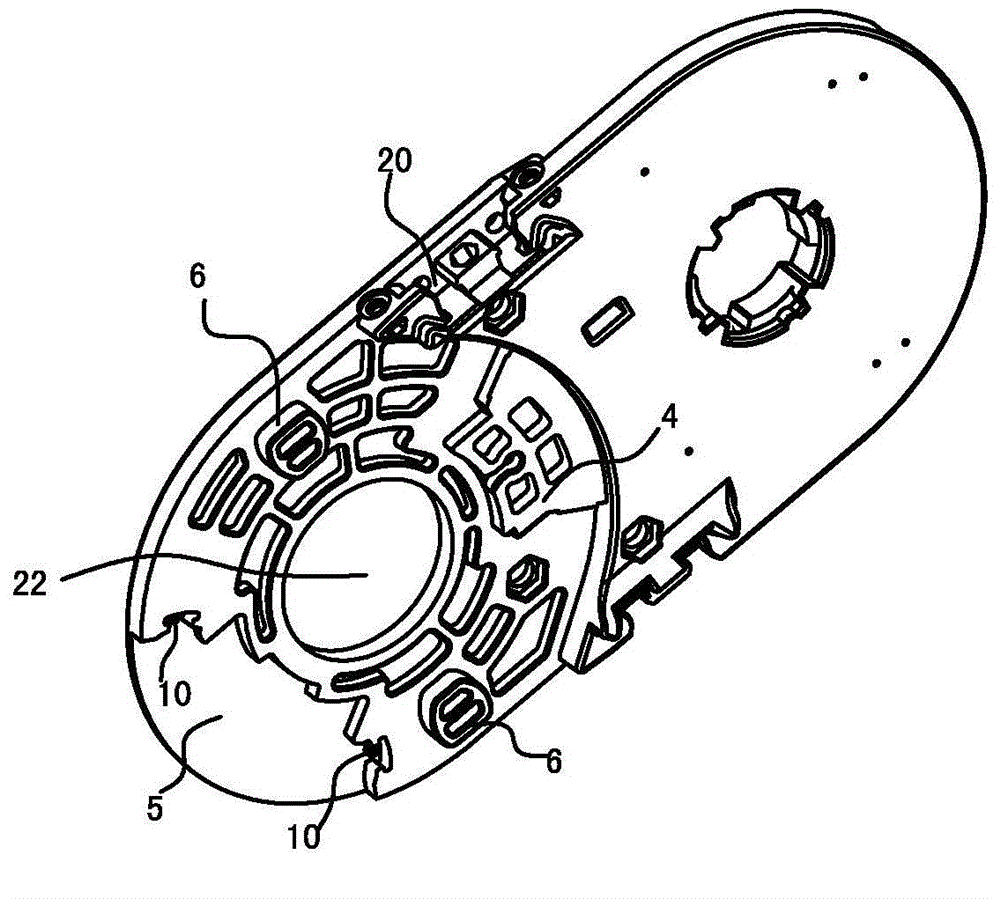

[0069] Embodiment one: see attached Figure 1-2 , attached Figure 5-18 , attached Figure 22 , a high-speed heavy-duty silent drag chain, which is composed of several chain links 1 with the same shape, size and structure connected end to end.

[0070] Wherein, each chain link 1 is composed of two chain plates 2 and a cross bar 3 fixedly connecting the two chain plates 2, the two chain plates 2 in each chain link 1 have the same shape, size and structure, and the chain The center line in the length direction of section 1 is arranged parallel and symmetrically to the datum.

[0071] The cross bar 3 has upper and lower layers. The top or bottom of the chain plate 2 is provided with a positioning groove 20. The positioning part of the cross bar 3 is fixed with the positioning groove 20 of the chain plate 2. In the assembled state, the positioning surface of the cross bar 3 Embed in the positioning groove 20 of the chain plate 2.

[0072] Between any two adjacent chain links 1...

Embodiment 2

[0092] Embodiment two: see attached Figure 19 , and the rest are the same as in Embodiment 1, except that each column groove structure is formed by a column groove structure located on the inner side and another column groove structure located on the outside arranged side by side in the radial direction of the circumference. That is to say, there is another column groove structure inside the outer column groove structure, and two column groove structures are arranged side by side along the radial direction of the circumference, which can further share the impact force on the chain plate 1 . In this embodiment, there are four post-groove structures and two block-shaped structures. The first post-groove structure is reflected on the chain plate 2 of the previous chain link 1 as a convex post 6, and the second post-groove structure is The structure is reflected in the arc-shaped groove 7 on the chain plate 2 of the previous chain link 1; the third column groove structure is refl...

Embodiment 3

[0094] Embodiment three: see attached Figure 20 As shown, the rest are the same as in Embodiment 1, the difference is that the four rotation limiting structures are composed of four column groove structures, and the rotation limiting structures of the four column groove structures are based on the center of the rotating connection Arranged at intervals in the circumferential direction. In this embodiment, the four rotation limiting structures are column-groove structures. The first column-groove structure is reflected on the chain plate 2 of the previous chain link 1 as a convex column 6, and the second column-groove structure Reflected on the chain plate 2 of the previous chain link 1 is an arc-shaped groove 7; the third column groove structure is reflected on the chain plate 2 of the previous chain link 1 as a convex column 6, and the fourth column groove structure Reflected on the chain plate 2 of the previous chain link 1 is an arc-shaped groove 7 .

[0095] In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com