High-efficiency tightly-coupled LLC resonance transformer

A resonant transformer and tight coupling technology, applied in the field of transformers, can solve the problems of reducing the efficiency of transformer energy transfer, discounting transformer energy transmission efficiency, reducing power supply efficiency and reliability, etc., achieving parameter accuracy and flexibility improvement, design and calculation Convenience and speed, the effect of improving energy transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

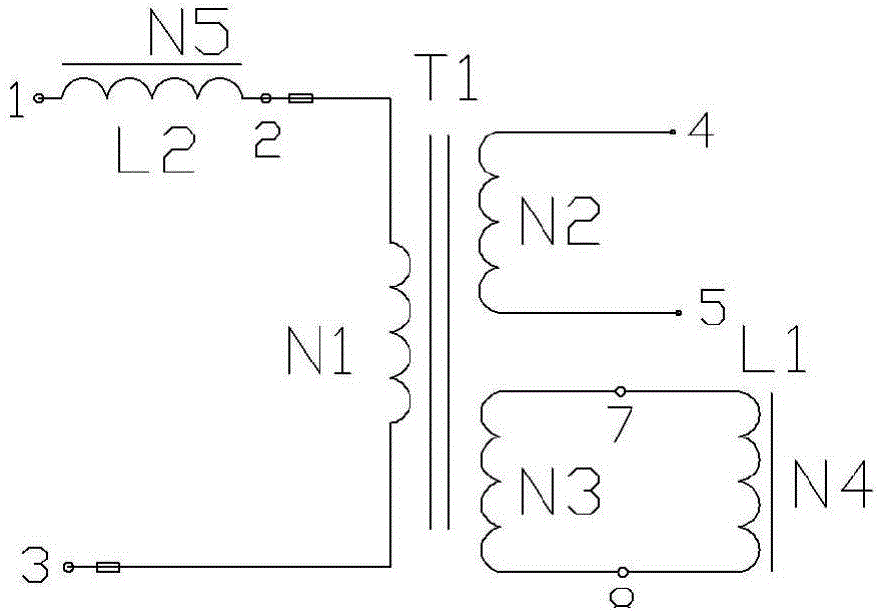

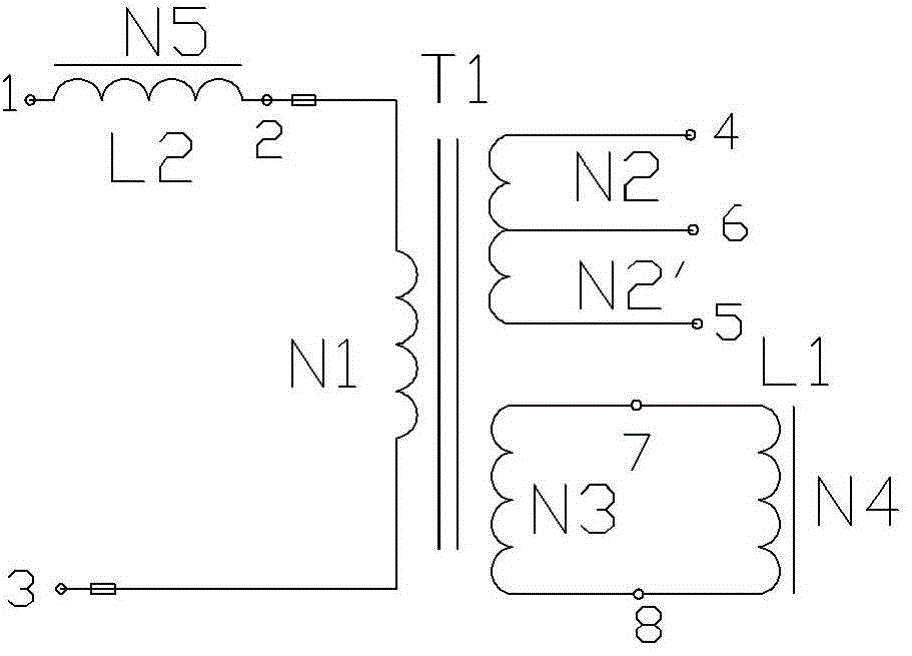

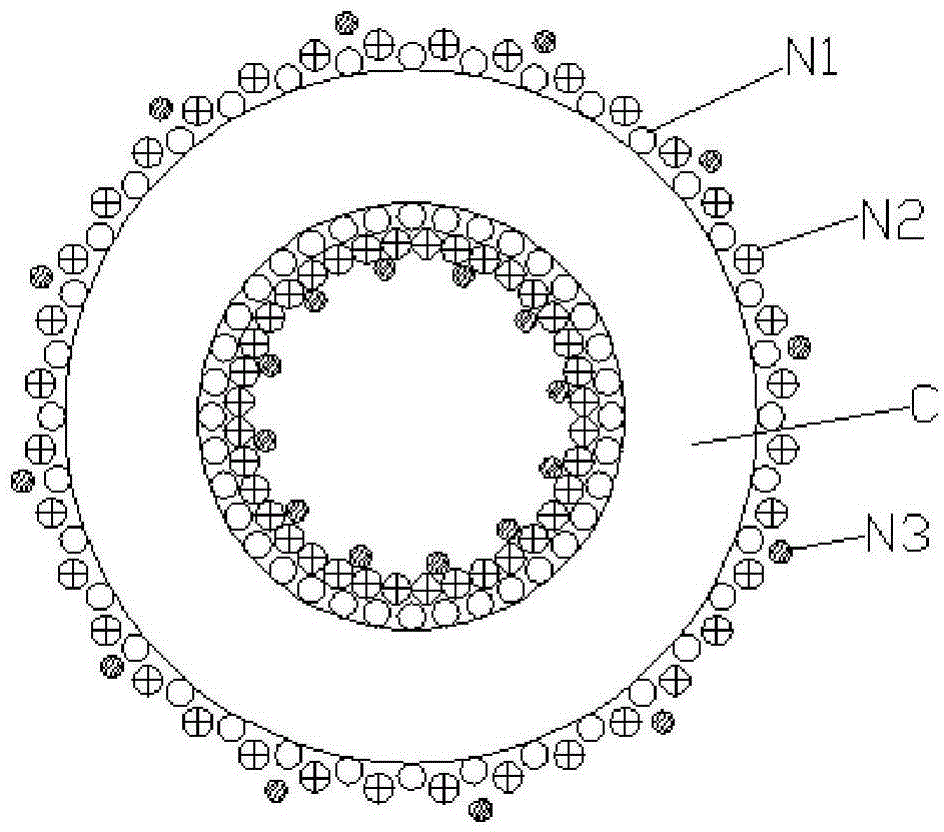

[0025] Such as Figure 1 to Figure 4 As shown, an embodiment of the present invention is composed of a ring-shaped main transformer T1 without an air gap, an output auxiliary inductor L1, and an input auxiliary inductor L2. The core C of the toroidal main transformer does not add an air gap. The primary N1 is wrapped with multi-strand enameled wire or flat copper tape and then evenly wound on the magnetic core. It can be wound clockwise or counterclockwise. The number of primary turns N1 is given by the formula (1 )Sure. The number of turns N2 of the first and secondary of the main transformer is determined by formula (2), which can be a winding with a center tap or a winding without a center tap. When there is no center tap, the first secondary N2 is wrapped with multi-strand enameled wire or flat copper tape and then evenly distributed and wound on the magnetic core. It can be wound clockwise or counterclockwise. With a center tap, the first secondary N2 and N2ˊ are wrappe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com