A method of obtaining DC pulse high voltage applied to grid-controlled x-ray tube

A pulsed high-voltage, applied technology, applied in the field of X-ray imaging, can solve the problems of soft rays harming the human body and the charge at the load end can not disappear instantly, and achieve the effect of reducing product cost and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

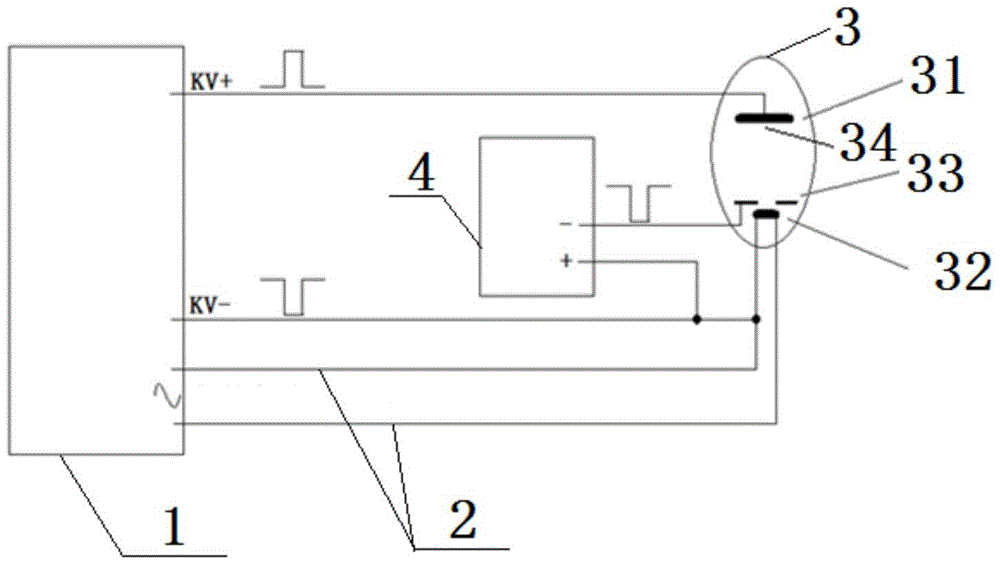

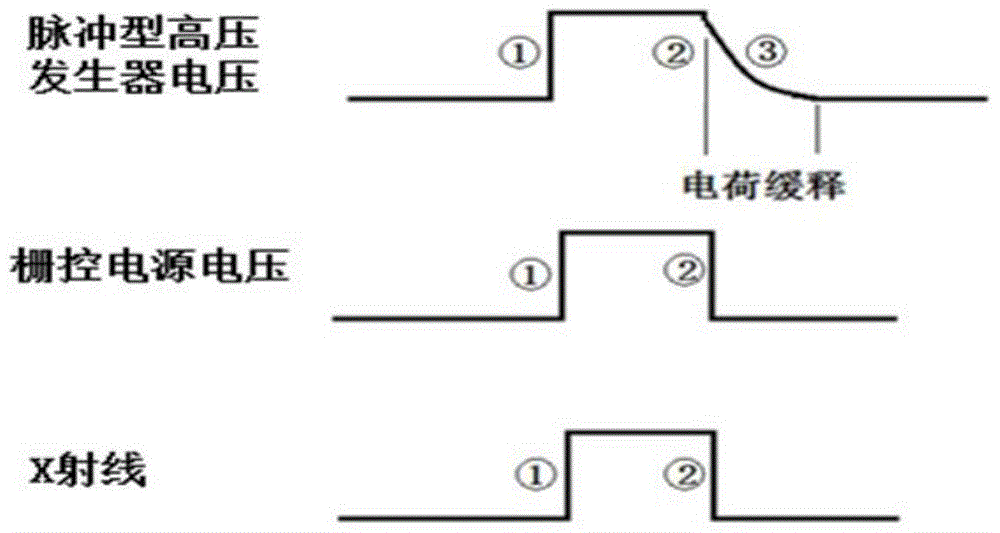

[0041] Such as figure 1 and image 3 As shown, a method for obtaining a DC pulsed high voltage applied to a grid-controlled X-ray tube in the present invention includes the following steps: starting the pulsed high-voltage generator, the grid-controlled power supply outputs a negative high voltage to the grid, and the rotating anode of the tube starts to accelerate Rotate, wait for the rotating anode to accelerate to the specified speed, the negative voltage of the grid control power supply is canceled, and at the same time (or delayed) the pulse high voltage generator starts the high voltage, at this time the high voltage directly reaches the cathode filament of the bulb and the anode target disk, because the grid is in conduction In the state, the electrons generated by the cathode filament quickly pass through the grid and bombard the anode target disk, generating X-rays at the focal point. When the set high-voltage time arrives, the pulse high-voltage generator stops out...

Embodiment 2

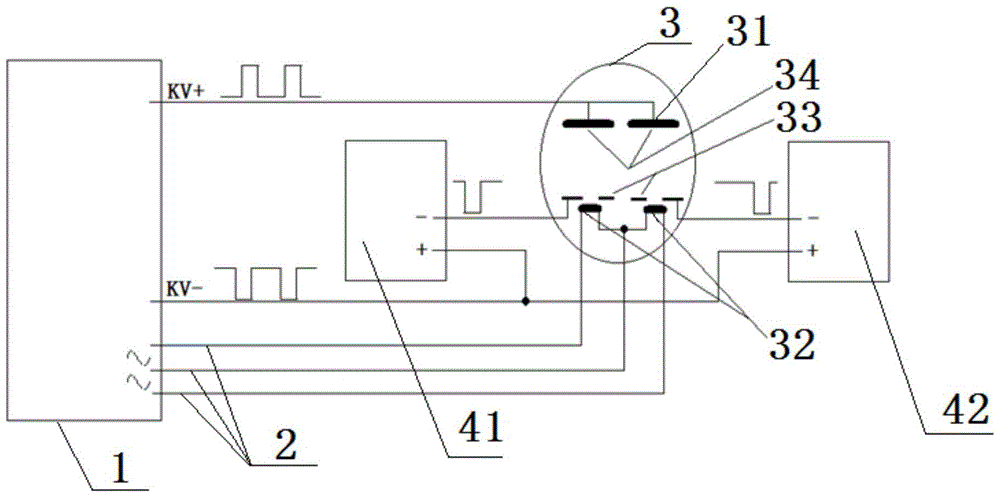

[0045] Such as figure 2 and Figure 4 As shown, a schematic diagram of the structure of the focal point in the tube used in the method for obtaining the DC pulse high voltage applied to the grid-controlled X-ray tube of the present invention, that is, to generate a focus requires a group of grid-controlled power supply, cathode filament and anode target Disk, and between the cathode filament and the anode target disk, there is a set of grids connected to the negative pole of the grid control power supply, and the two sets are arranged in parallel; for example Figure 5 The structure schematic diagram of two sets of grid control power supplies, one cathode filament and two anode target discs is required to generate two focal points as shown, that is, the cathode filament is located in the middle, and the anode target discs are on both sides, and the cathode filament and the anode target disc are set There is a gate connected to the negative pole of the gated power supply. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com