Method for quickly producing uniform core-shell type alloy solder balls

A core-shell, uniform technology, applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of low yield and uneven particle size, and achieve the effects of high yield, complex preparation process, and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

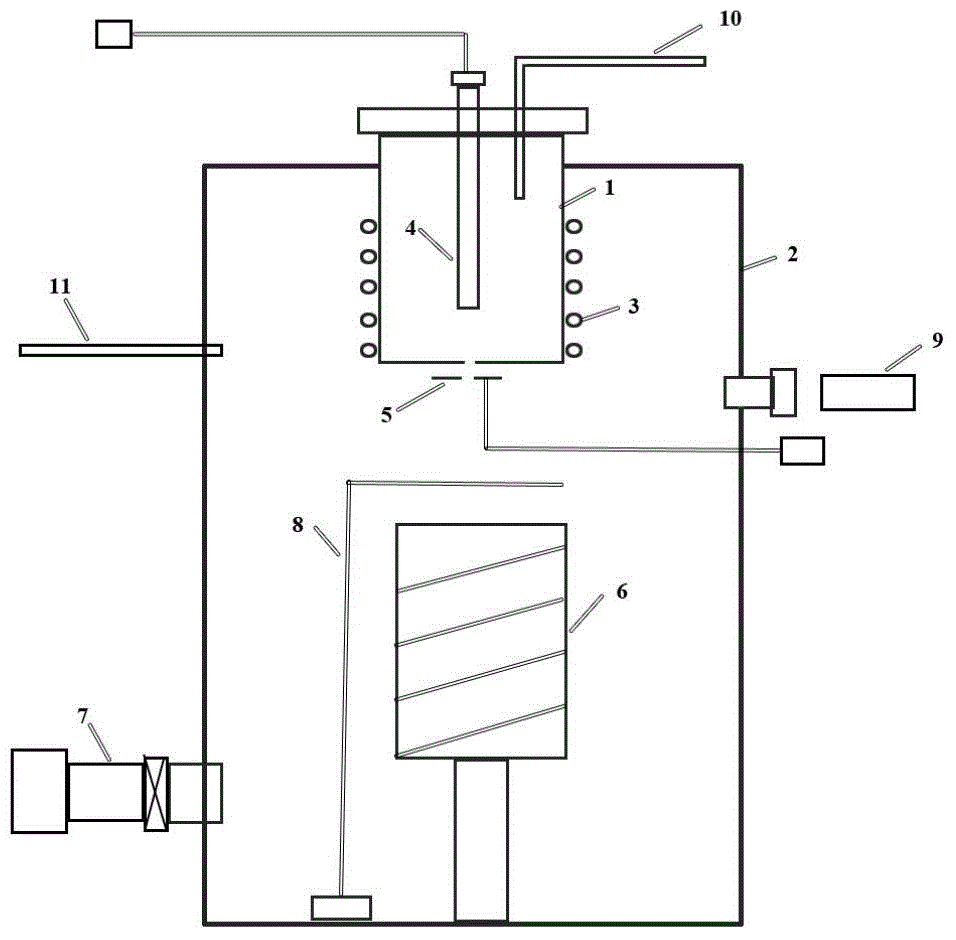

[0031] as attached figure 1 As shown, in the device for preparing core-shell solder balls used in the present invention, 1 is a quartz crucible, 2 is a vacuum chamber, 3 is an induction heating system, 4 is a piezoelectric oscillation system, 5 is an electrode plate, and 6 is a liquid Nitrogen spiral cooling collection device, 7 is a vacuum pump, 8 is a baffle, 9 is an image monitoring system, 10 is a protective gas delivery system connected to a crucible, and 11 is a protective gas delivery system connected to a vacuum chamber.

[0032] The equipment used includes:

[0033] 1) A vacuum chamber connected to a vacuum pump through a gas pipeline with a vacuum valve.

[0034] 2) A quartz crucible with an induction heating system located above the vacuum chamber.

[0035] 3) An image monitoring system, including a strobe, a video camera and a micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com