Method for carrying out solar thermal decomposition on H2O and/or CO2 employing perovskite dispersed by different carriers

A perovskite, CO2 technology, applied in chemical instruments and methods, hydrogen production, energy input, etc., can solve the problems of carrier modification and loading methods that are still less researched, and achieve improved production rate and cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of perovskite active material LaFe by combustion method 0.7 co 0.3 o 3 . Weigh 10mmol of lanthanum nitrate, 7mmol of ferric nitrate, 3mmol of cobalt nitrate, 40mmol of glycine and dissolve them in deionized water, stir at room temperature for 30min, stir in a water bath at 80°C until evaporated to dryness, dry in an oven at 120°C until foaming, and grind Grind and bake at 700°C for 4h.

Embodiment 2

[0038] Preparation of perovskite active material LaFe by microemulsion method 0.7 co 0.3 o 3 . A certain proportion of alkanes, alcohols, surfactants, and corresponding metal salt solutions form microemulsion 1, and the same proportion of alkanes, alcohols, and surfactants form microemulsion 2 with alkali solution, mix microemulsions 1 and 2, stir, and age , washed, dried, roasted.

Embodiment 3

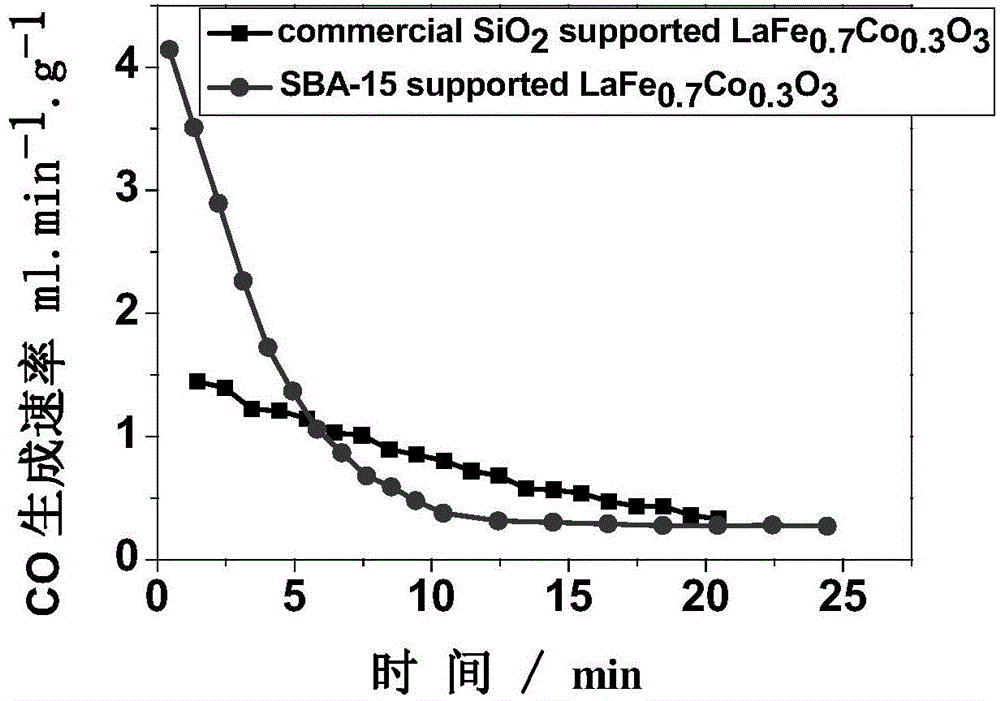

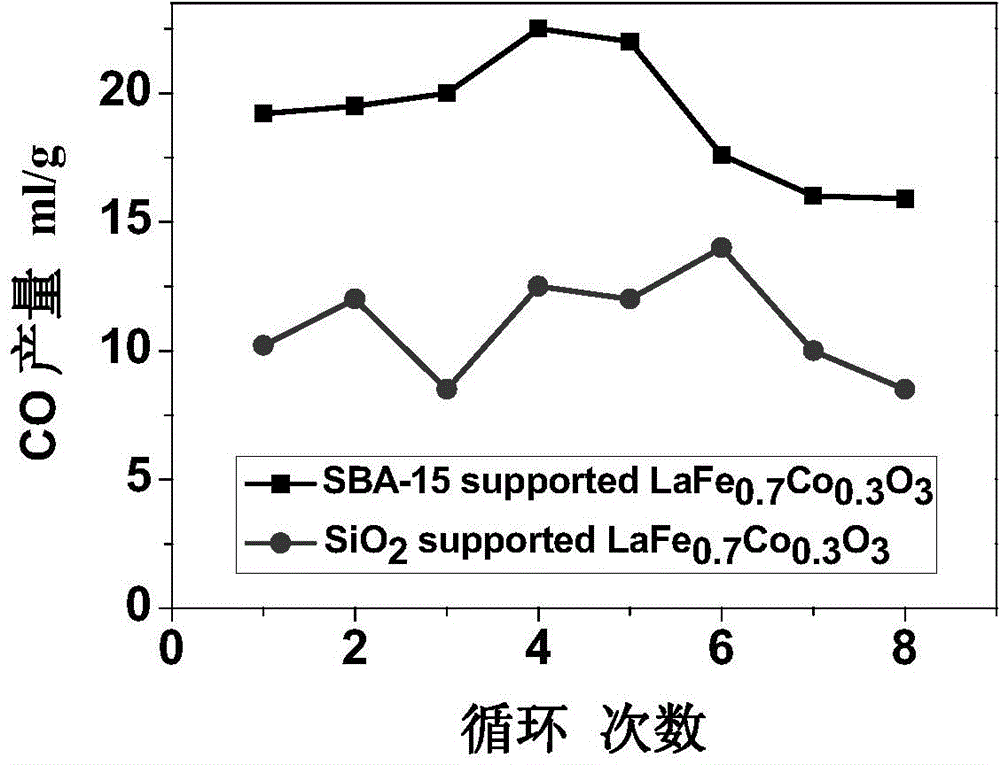

[0040] Active materials were loaded on the surface of SBA-15. Weigh 0.1g active material, 0.3g SBA-15, fully grind, with 25wt%LaFe 0.7 co 0.3 o 3 / SBA-15 means.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com