Environment-friendly adhesive composition and tape manufactured using the same

An environmentally friendly, adhesive technology, applied in the direction of film/sheet adhesives, adhesive types, ester copolymer adhesives, etc., to achieve high functional properties, improved tack and flame retardancy, high tack Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

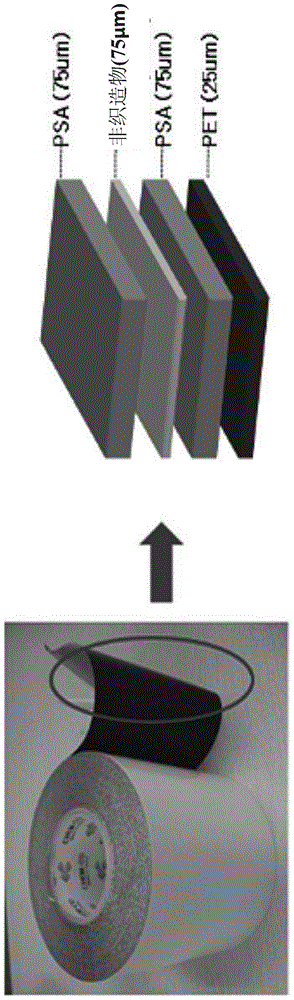

[0038] Adhesive compositions were formed according to the composition of the tackifier base in Table 1 below and the composition ratios in Table 2 below. Such as image 3 Shown to manufacture tapes with complex structures. A 75 μm thick layer of tackifier PSA was coated on a black PET film, a 75 μm thick nonwoven layer was laminated on it, a 75 μm thick layer of tackifier PSA was coated again, and the prepared adhesive was coated Covered on PET film. Once the adhesive was applied to the PET film, the odor was reduced by fully evaporating the odor elements and gradually increasing the temperature during the drying process from an initial moderate temperature to a temperature of about 110°C to maximize inhibition of tackifier coating. Tape samples were produced by reducing the odor by volatilizing the remaining odor elements during long-term aging at a temperature of about 43°C.

[0039] Table 1

[0040] The composition of tackifier base material (unit: parts by weight)

...

experiment example

[0047] Experimental Example: Measurement of Physical Properties

[0048] The physical properties of the samples manufactured according to Examples 1 to 3 and Comparative Examples 1 to 3 were determined by the following methods. The results are described in Table 3 below. The physical property results described in Table 4 below provide an average of five tape samples measured except for the highest and lowest values. Its test method is described as follows:

[0049] (1) Determination of VOC amount: The discharged VOC amount is measured by the standard MS 300-55 test method. The unit of emitted VOC is μg / m 3 .

[0050] (2) Odor determination: The amount of odor was determined by the standard MS 300-34 test method. The conversion ratio is obtained by dividing the weight average molecular weight (Mw) by the number average molecular weight (Mn). Set up a reference vs. standard comparison with an odor rating of 4 or more scales. An increase in conversion ratio represents a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com