Combined aluminum mould plate system

An aluminum formwork, combined technology, applied in the direction of formwork/formwork member, formwork/formwork/work frame, formwork/formwork/work frame connector, etc., can solve the problem of poor consistency of pouring products and difficult wall size Guarantee, formwork takes up a lot of space and other problems, to achieve the effect of light weight, light weight, improve construction speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

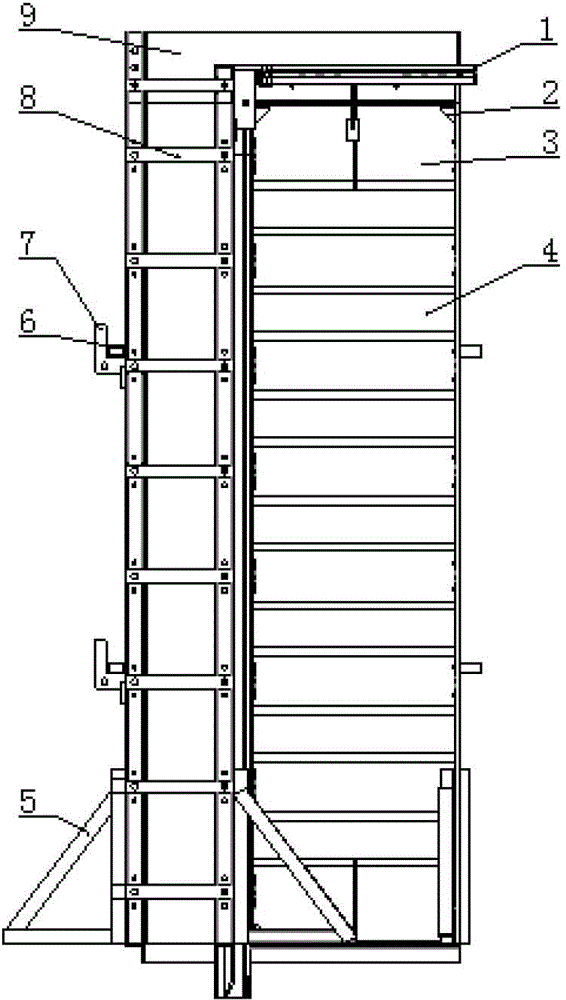

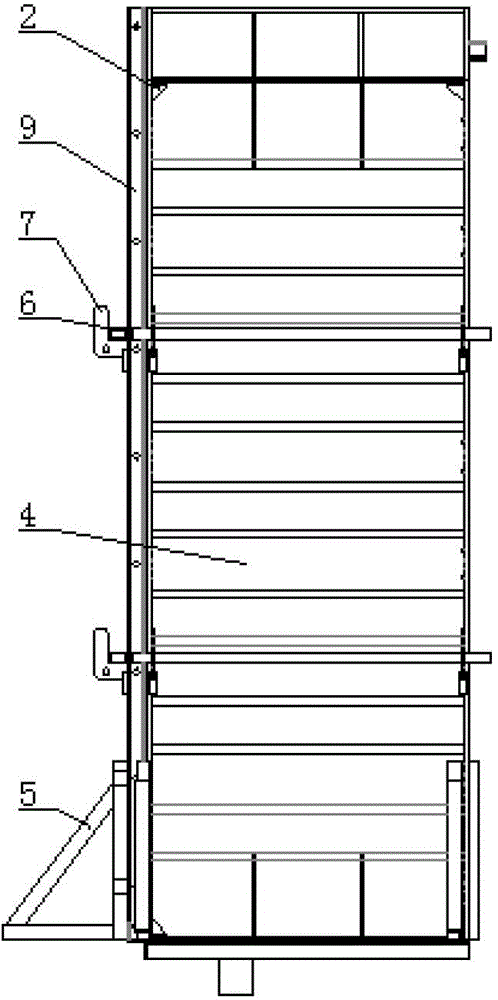

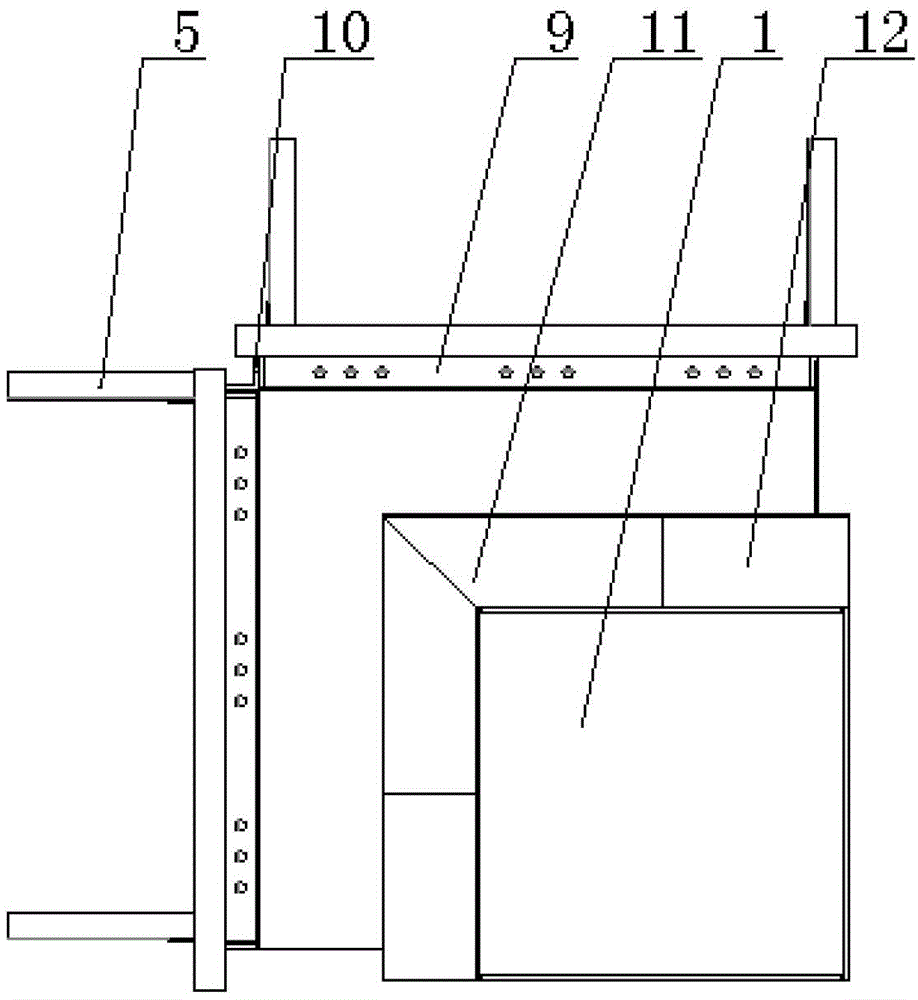

[0039] A combined aluminum formwork system, comprising an exterior wall formwork 9, an interior wall formwork 3 and a top formwork 1, the exterior wall formwork and the interior wall formwork are set opposite to each other, the top formwork is fixed to the upper end of the interior wall formwork, the exterior wall formwork and the interior wall formwork The lower ends are respectively fixed with triangular stabilizing frames 5, and the inner sides of the four corners of the outer wall formwork, inner wall formwork and top formwork are respectively fixed with joint plates 2, and the back corrugated card 7 is fixed on the outer wall formwork, and the back corrugated card and the outer wall formwork Reinforced steel pipes 6 are installed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com